Conduit for Outdoor Network Cable: The 1 Essential Guide

Why Conduit is Essential for Outdoor Network Runs

Conduit for outdoor network cable provides critical protection that direct burial cables simply cannot match on their own. While outdoor-rated cables are designed to withstand environmental conditions, they remain vulnerable to physical damage from shovels, rocks, and rodents that can cause costly network outages.

Best conduit options for outdoor network cable:

- PVC (Schedule 40/80) – Most cost-effective, excellent UV resistance, easy installation

- Rigid Metal Conduit (RMC) – Superior EMI shielding, maximum durability, best for industrial environments

- Electrical Metallic Tubing (EMT) – Good balance of protection and cost, lighter than RMC

- Liquid-Tight Flexible Non-Metallic (LFNC) – Ideal for short runs requiring flexibility

- HDPE Corrugated – Excellent for direct burial, crush-resistant yet flexible

As one installer noted: “Normal CAT5E and CAT6 cables will deteriorate quickly when exposed to outside conditions like weather, temperatures, and humidity.” Even with outdoor-rated cables, conduit adds a crucial layer of physical protection and future-proofing that saves money long-term.

The reality is that conduits will fill with water due to condensation – but this doesn’t diminish their value. The primary benefits are protecting against physical damage, providing a pathway for future cable upgrades, and shielding against electromagnetic interference when using metallic conduit.

I’m Corin Dolan, owner of AccuTech Communications. With over 30 years of experience installing network systems across Massachusetts, New Hampshire, and Rhode Island, I know that proper conduit installation is the key to a long-lasting network.

The Conduit vs. Direct Burial Cable Debate

While some “direct burial” cables don’t technically require conduit, our experience shows this is a risky shortcut. Direct burial cables have robust, waterproof jackets, but they offer little defense against physical damage from shovels, shifting rocks, or rodents. Conduit provides a crucial physical shield and simplifies future upgrades—pulling a new cable through a smooth pipe is far easier than re-digging a trench. Seasoned installers agree: using outdoor-rated cable inside a conduit is the superior method for long-term reliability and protection.

For more insights into what our community thinks about this, you can check out this forum discussion: Is conduit necessary when using outdoor grade ethernet cable on …

Key Benefits of Using Conduit

The advantages of installing conduit for outdoor network cable extend far beyond simple cable protection. It’s about building a resilient, future-proof network infrastructure.

Here are the key benefits we champion:

- Physical Damage Prevention: Conduit provides a hard barrier against cuts from garden tools, shifting soil, and rodents, shielding your sensitive network lines.

- Weather Resistance: Conduit adds an extra layer of defense against UV radiation, extreme temperatures, and moisture. It keeps bulk water and debris away from the cable jacket, preserving its integrity.

- Simplified Maintenance and Upgrades: Need to replace a damaged cable or upgrade to a higher category? With conduit, you simply pull the new cable through without re-digging. This well-planned infrastructure can also increase property value.

- EMI/RFI Shielding (Metallic): For installations near power lines or motors, metallic conduit (like RMC or EMT) shields Ethernet signals from electromagnetic interference (EMI), ensuring consistent performance.

- Future-Proofing: Conduit allows for adding more cables later without new trenching. Slightly oversizing your conduit is a small investment that saves significant future effort.

As specialists in underground fiber optic cable installation, we know the importance of robust pathways. Whether it’s copper or fiber, protecting your investment with conduit is a non-negotiable best practice. Learn more about our approach to underground installations here: Underground Fiber Optic Cable Installation

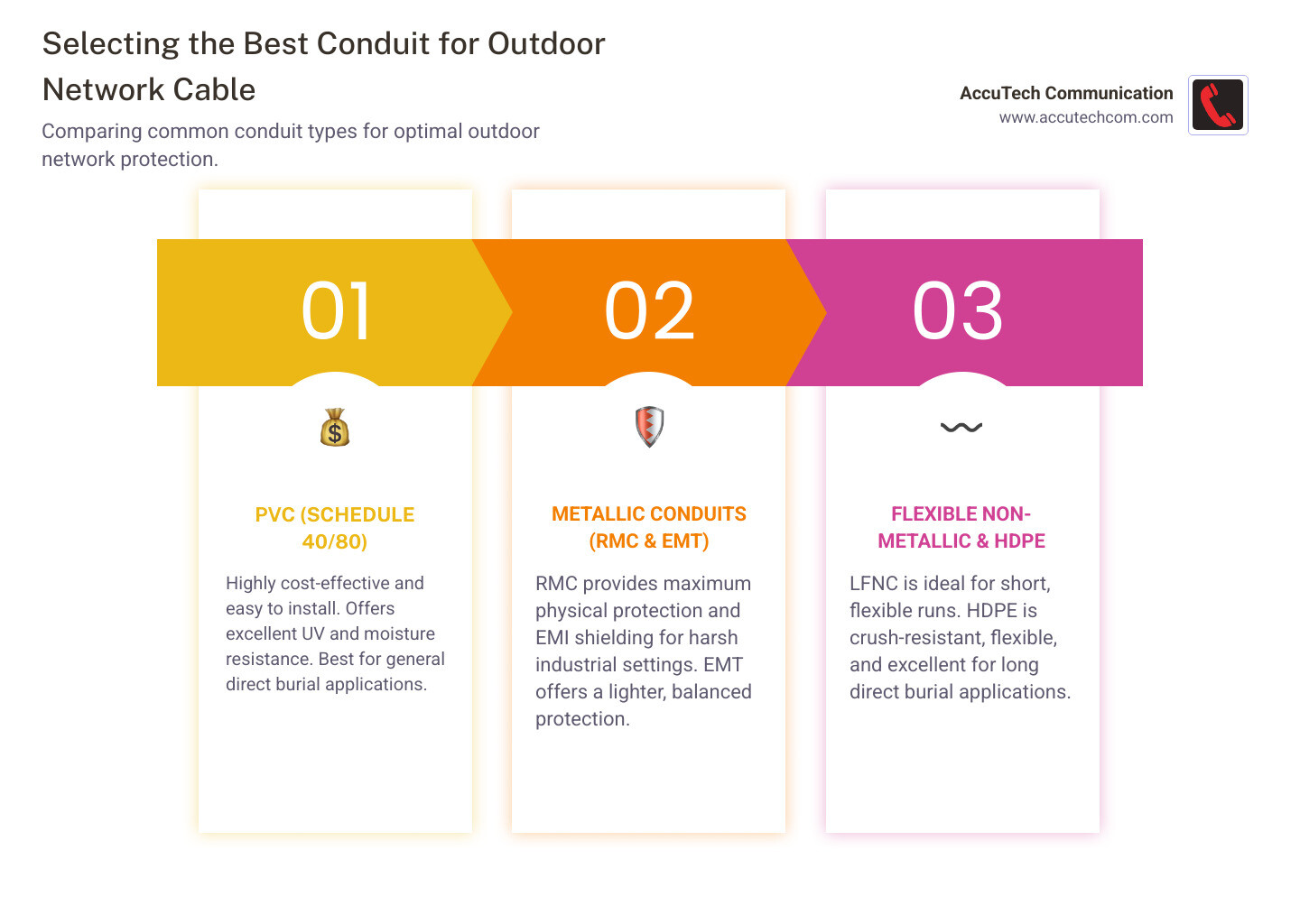

Selecting the Best Conduit for Outdoor Network Cable

Choosing the right conduit for outdoor network cable depends on your environment, budget, and required level of protection. The best fit will provide the right armor for your data cables based on your unique needs.

A Breakdown of Suitable Conduit Types

Let’s explore the common types of conduit we use for outdoor network installations:

- Rigid PVC (Polyvinyl Chloride): A popular choice for residential jobs, PVC is cost-effective, lightweight, and resistant to moisture, corrosion, and UV rays. It’s easy to install but offers less impact protection than metal and no EMI shielding. We recommend 3/4-inch or 1-inch sizes for future expansion.

- Rigid Metal Conduit (RMC): Made from galvanized steel, RMC offers the best protection against physical impact and excellent EMI shielding, making it ideal for industrial settings or areas near power lines. However, it is heavier, more expensive, and requires special tools for installation.

- Electrical Metallic Tubing (EMT): Often called “thin-wall conduit,” EMT offers a good balance of protection, cost, and ease of installation. It provides some EMI shielding and is easier to bend than RMC, making it suitable for many commercial applications where extreme durability isn’t required.

- Liquid-Tight Flexible Non-Metallic Conduit (LFNC): Known by brand names like “Carflex,” this flexible PVC conduit is perfect for short, wet, or oily runs, such as connecting an outdoor camera to a junction box. It’s not intended for long burial runs and offers less physical protection than rigid types. For more on flexible options, see: What Kind of Flexible Electrical Conduit is Used for Outside?

- High-Density Polyethylene (HDPE) Corrugated Conduit: Excellent for direct burial, HDPE conduit is flexible, crush-resistant, and lightweight. Its corrugated design bends easily around obstacles, protecting cables from shifting ground and rocks, though it provides no EMI shielding. You can learn more about HDPE conduit from manufacturers like Dura-Line: HDPE Standard | Dura-Line

When making your choice, always consider the specific conditions your cables will face. For example, if you have power lines nearby, a metallic conduit might be your best bet to keep your data signals clear.

Choosing the Right Ethernet Cable for Inside Conduit

Conduit isn’t a magic shield against all elements; moisture from condensation can still accumulate inside. Therefore, using the right cable is critical.

Here’s what we recommend to make sure your Ethernet cable is up to the task:

- Outdoor-Rated (CMX) Jacket: Always use cables with a CMX or “outdoor” rating. Their robust LLDPE or HDPE jackets are UV-resistant and far more durable than standard indoor PVC jackets. An indoor cable, even in conduit, will break down quickly when exposed to outdoor elements.

- Shielded Twisted Pair (STP) vs. Unshielded Twisted Pair (UTP):

- We strongly recommend STP (Shielded) cables for outdoor runs near power lines or other interference sources to protect the signal. Proper grounding is essential for STP to be effective.

- UTP (Unshielded) cables may suffice for short runs far from interference, but STP offers greater peace of mind for a minimal extra cost.

- Cat6 or Cat6a:

- Cat6 is affordable and supports speeds up to 10 Gbps over shorter distances (55m), sufficient for most needs like security cameras or outdoor Wi-Fi.

- For longer runs or to future-proof for higher bandwidth, Cat6a supports 10 Gbps over the full 100-meter length.

- Gel-Filled Cables: For maximum moisture protection in very wet environments, consider gel-filled cables. A special gel surrounds the wires, preventing water from migrating along the cable if the jacket is compromised.

By pairing the right outdoor-rated cable with the perfect conduit for outdoor network cable, you’re building a resilient connection that will serve you well for years. For more details on our selection of outdoor network cables, check out our options here: Outdoor Network Cable

Planning Your Installation: Sizing and Path

Once you’ve selected your conduit for outdoor network cable, proper planning is the next step. This involves choosing the right conduit size and carefully mapping its route to avoid future problems.

How to Correctly Size Your Conduit for Outdoor Network Cable

Undersized conduit makes pulling cables difficult and can cause damage, while also preventing future upgrades. We adhere to industry best practices for fill ratios.

The 40% Rule is key: for the initial pull, cables should not exceed 40% of the conduit’s internal area. This reduces friction and protects cables from damage during installation.

For future expansion, the total fill should never exceed 60%. This leaves enough room to add cables later without binding.

Always consider the cable’s outer diameter (OD). We recommend a minimum conduit trade size of 3/4 inch for network cables.

Here’s a quick guide for standard Ethernet cables (approx. 6.00mm OD):

- 3/4-inch PVC conduit: Holds up to 4 cables.

- 1-inch PVC conduit: Holds up to 7 cables.

- For thicker Cat6a cables (around 7.00mm OD), a 1-inch PVC conduit will comfortably hold up to 5 cables.

For runs with many bends or long distances, consider using a larger conduit size to reduce friction.

Mapping Your Cable Route

Before digging, a well-thought-out route is essential.

- Call Before You Dig: This is non-negotiable. Contact your local utility locator service to mark all buried gas, water, and electrical lines. This is the first step for safety on every project in Massachusetts, New Hampshire, and Rhode Island.

- Burial Depth: We recommend burying conduit at least 12 inches deep, with 18-24 inches being ideal for protection against digging and frost heave. Always verify local building and electrical codes, as requirements for low-voltage lines can vary.

- Avoiding Power Lines: Maintain a safe distance between your network conduit and any electrical power lines to prevent signal interference and safety hazards. More distance is always better.

- Drip Loops and Sealing: Where a cable exits the conduit, create a downward drip loop so water drips off instead of flowing into equipment. Seal conduit entry points at buildings with weatherproof outdoor boxes and silicone caulk to prevent moisture intrusion. Ensure the conduit does not slope towards the building.

By carefully following these planning steps, you’re building a rock-solid foundation for a reliable and long-lasting outdoor network. For even more detailed guidance, be sure to check out our comprehensive Conduit Installation Guide.

Best Practices for a Flawless Installation

With planning complete, it’s time for installation. Following best practices when pulling cable through conduit for outdoor network cable is crucial for a reliable, damage-free setup.

Pulling Cable Without Damage

The goal is to get cables through the conduit without kinks, scuffs, or stress.

- Pulling Tension: Do not exceed 25 pounds of pulling tension on Ethernet cables, as this can stretch and damage the internal conductors, leading to network failure.

- Cable Lubricant: Use a quality, synthetic wax-based lubricant to dramatically reduce friction, making the pull smoother and safer for the cable jacket.

- Pull String and Tools: Always install a pull string in your conduit for current and future use. Attach the cable to the string with a fish tape. For long or complex runs, a specialized pull sock and swivel grips the cable securely and prevents twisting.

- Bends: Respect the cable’s minimum bend radius. Limit conduit runs to no more than two 90-degree bends between pull points to avoid excessive friction. For longer runs or those with more bends, install intermediate junction boxes.

- Protect Entry/Exit Points: Use protective bushings at the ends of the conduit to prevent the cable jacket from being torn on sharp edges during the pull.

When it comes to cable pulling, patience and the right tools are key. Take your time, use lubricant, and let your tools do the hard work!

Safety, Grounding, and Long-Term Protection

Electrical safety and long-term protection are paramount for any outdoor network.

- Grounding: If using shielded Ethernet cables, they must be properly grounded at one end (typically the equipment side). This drains electrical interference and protects against ESD and lightning. Attach a grounding wire to a grounded electrical panel or rod.

- Surge Protection: Install outdoor-rated surge protectors at both ends of the cable run. These devices are essential for lightning protection, diverting harmful electrical surges away from your sensitive network equipment.

- Sealing Conduit Ends: Use expanding foam, rubber caps, and silicone caulk to seal conduit ends. This prevents insects, rodents, debris, and bulk water from entering.

- Weatherproof Fittings: Ensure all outdoor connectors and fittings are weatherproof and properly sealed with tape or sealant to prevent moisture ingress and corrosion.

By prioritizing these safety and protection measures, you’re building a robust, reliable, and safe outdoor network infrastructure. For more on protecting your network, explore topics like innerduct and its importance: What is Innerduct and Why is it Important for Network Cabling Installation?

Frequently Asked Questions about Outdoor Conduit

We know you’ve got questions about getting your network outdoors. Here are some of the most common questions we hear, answered with our years of experience.

How deep should I bury conduit for Ethernet cable?

We recommend a burial depth of at least 12 inches, with 18-24 inches being ideal for protection against accidental digging. However, you must always check your local building and electrical codes, as specific requirements for low-voltage lines vary by location.

Can I run power and Ethernet cables in the same conduit?

No. This is prohibited by the National Electrical Code (NEC) for two critical reasons. First, it causes electromagnetic interference (EMI) that can disrupt your network signal. Second, it is a significant fire and electrical shock hazard. Always use separate conduits for power and data cables.

Do I still need outdoor-rated cable if I use conduit?

Yes, this is highly recommended. Conduits are not perfectly sealed and will accumulate moisture from condensation over time. An indoor-rated cable will degrade and fail in these conditions. Using an outdoor-rated (CMX) or direct-burial cable provides a vital second layer of protection, ensuring the cable itself can resist the moisture inside the conduit for long-term reliability.

Your Partner for Reliable Outdoor Connectivity

A properly installed conduit for outdoor network cable system is the best investment for your outdoor network, ensuring reliable performance and simplifying future upgrades. Following best practices creates a robust connection that will withstand New England’s harsh weather for decades.

At AccuTech Communications, we’ve been protecting network investments with high-quality installations since 1993. Our certified technicians understand the unique challenges of our region—from rocky soil to varying local codes across Massachusetts, New Hampshire, and Rhode Island.

Our solutions are not just built to work; they’re built to last. We have the expertise to design and install a system that avoids common pitfalls and costly future failures.

For professional, standards-based installations you can count on, trust the experts at AccuTech Communication. We ensure your project is done right the first time.

Ready to protect your outdoor network investment? Explore our Structured Cabling Services to get started.