Cat 5 Cable Cost: 7 Powerful Savings in 2025

Understanding Cat 5 Cable Costs in Today’s Market

Cat 5 cable cost varies widely based on length, quality, and where you buy it. Here’s what you need to know:

Quick Cost Overview:

– Patch cables (1-25 ft): $2-$25 each

– Bulk cable per foot: $0.10-$0.25

– 1000 ft spools: $80-$150

– Installation labor: $45-$75 per hour

While Cat 5 cables are becoming less common due to newer standards like Cat 6, they’re still preferred in many environments because they’re cost-effective for specific applications.

Cat 5 cables support speeds up to 100 Mbps at 100 MHz frequency. They work perfectly for basic networking needs, VoIP phone systems, and legacy equipment that doesn’t require gigabit speeds.

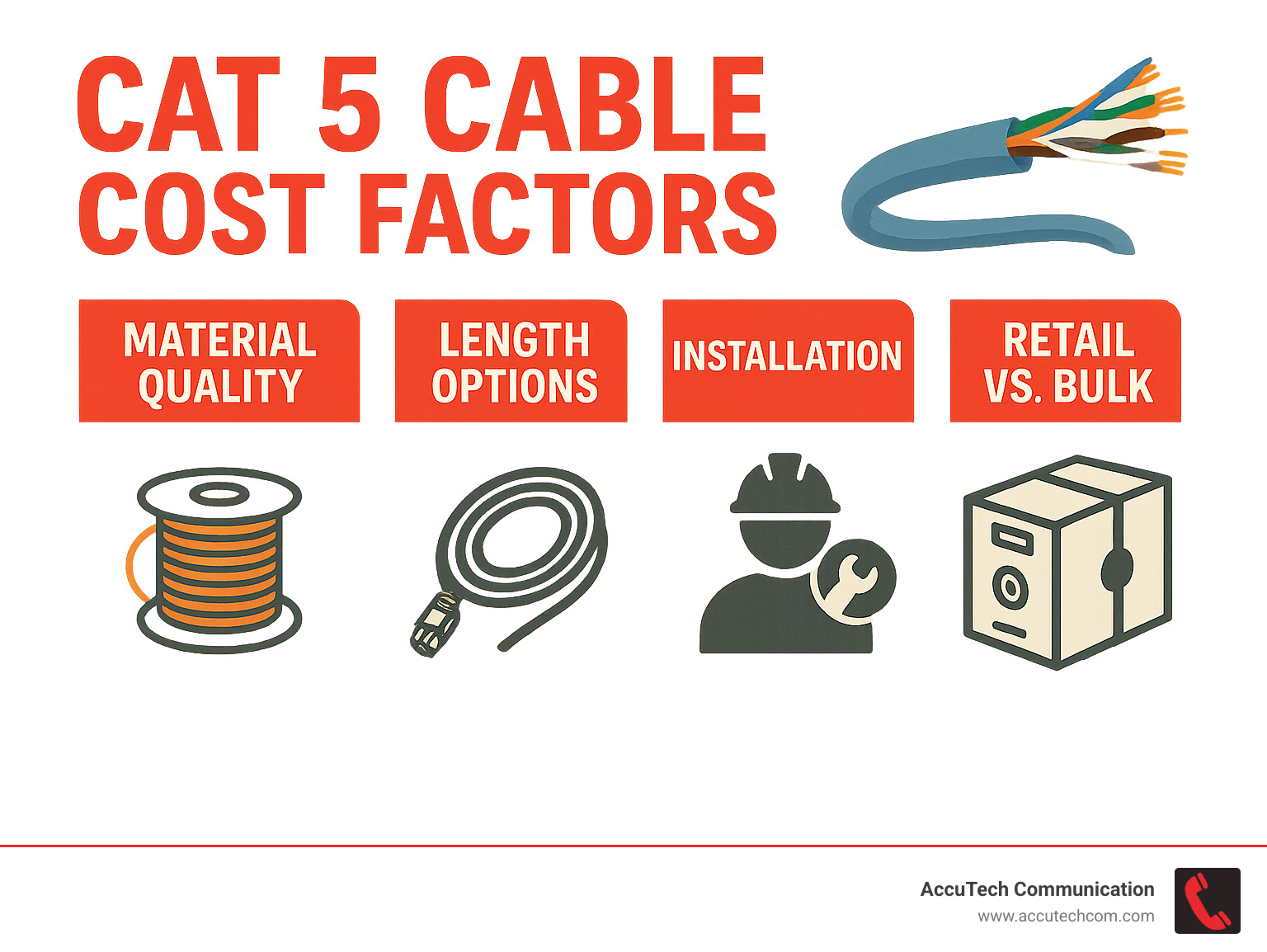

Key factors affecting price include:

– Cable length and gauge

– Copper purity (pure copper vs. copper-clad aluminum)

– Special features (shielding, plenum rating, outdoor jackets)

– Brand and retailer markup

– Bulk vs. retail purchasing

I’m Corin Dolan, owner of AccuTech Communications, and I’ve been helping businesses steer cat 5 cable cost decisions and network infrastructure upgrades across Massachusetts, New Hampshire, and Rhode Island since 1993. Through thousands of installations, I’ve learned that understanding true cable costs – including hidden expenses – saves businesses significant money and prevents costly mistakes.

Cat 5 cable cost further reading:

– cat6a ethernet cable 1000 ft

– cat6a outdoor ethernet cable

– cat6a patch cable

What Is Cat 5 Cable & Why It Still Matters in 2024

Cat 5 cable is the reliable workhorse that helped build the internet as we know it today. While it might not be the flashiest option anymore, this unshielded twisted pair (UTP) cable still has plenty to offer in 2024 – especially when you’re watching your cat 5 cable cost budget.

Cat 5 stands for “Category 5,” and inside each cable, you’ll find four pairs of copper wires twisted together in a specific pattern. This twisting is engineered to keep electromagnetic interference from messing with your data signals.

After three decades of installing network cables across Massachusetts, New Hampshire, and Rhode Island, I’ve seen plenty of situations where Cat 5 is still the smart choice. The 100 Mbps speed limit might sound slow compared to newer cables, but it’s plenty fast for many applications. Plus, Cat 5 cables work great for Power over Ethernet (PoE) devices like IP phones and security cameras.

Cat 5 Performance Specs

Cat 5 cables support 10/100 Base-T Ethernet, which means they handle both 10 Mbps and 100 Mbps speeds. The 100 MHz bandwidth is why you can’t push gigabit speeds through Cat 5.

The unshielded twisted pair design uses four color-coded wire pairs. Each pair twists at a different rate, which means less interference and cleaner signals.

Key specs: 100 Mbps maximum speed, 100 MHz bandwidth, and a 328-foot maximum run length. The cables typically use 24 AWG conductors with 100-ohm impedance.

Typical Use-Cases in 2024

You might wonder who still uses Cat 5 cables when faster options exist. The answer? Plenty of smart businesses and homeowners who understand that matching cable performance to actual needs saves money.

Home streaming is a perfect example. If your internet service delivers 50 or 75 Mbps, upgrading to expensive Cat 6 cables won’t make Netflix load any faster. Cat 5 handles those speeds beautifully while keeping your cat 5 cable cost reasonable.

VoIP phone systems love Cat 5 cables. Voice calls use minimal bandwidth, and these cables easily carry both voice signals and power to desk phones.

CCTV and security cameras represent another sweet spot for Cat 5. Many IP cameras don’t need gigabit speeds, especially older models or basic monitoring setups.

IoT sensors and building automation devices are Cat 5’s newest fans. Temperature sensors, door controllers, and smart building systems typically need basic connectivity that Cat 5 provides reliably and affordably.

Cat 5 Cable Cost Breakdown

When you’re planning a network project, understanding cat 5 cable cost means looking beyond the sticker price. The cable market has different pricing tiers based on where you shop and what quality you choose.

Retail stores offer convenience when you need something today, but you’ll pay more for that instant gratification. Wholesale suppliers and online vendors typically offer better pricing, especially for larger projects.

The biggest factor driving cat 5 cable cost up or down? What’s actually inside that cable jacket. Pure copper conductors cost more than copper-clad aluminum (CCA) alternatives, but pure copper provides better performance and meets UL listing requirements – something we always recommend for permanent installations.

Don’t forget about installation costs when budgeting your project. In our experience across Massachusetts, the labor often costs more than the cable itself.

| Cable Type | Patch Cable Price | Bulk Price Range |

|---|---|---|

| Basic Cat 5 | Higher per foot | Lower volume pricing |

| Standard Cat 5 | Mid-range pricing | Best value option |

| Premium Cat 5 | Highest cost | Specialized applications |

Average cat 5 cable cost per foot

The cat 5 cable cost per foot varies depending on what you’re buying and where you shop. Budget options start at the lower end but often use copper-clad aluminum conductors and basic PVC jackets. While these save money upfront, they might not meet electrical codes for commercial installations.

Standard quality cables hit the sweet spot for most projects. These feature pure copper conductors with CMR (riser) rated jackets – exactly what we typically recommend for business installations.

Premium options cost more but include features like plenum rating for air handling spaces, outdoor UV resistance, or improved shielding.

Big-box stores typically charge higher per-foot rates, while local electrical suppliers often offer better pricing for contractors and bulk purchases. Online suppliers frequently provide the best rates if you can handle shipping costs and wait times.

cat 5 cable cost for bulk 1000 ft spools

Buying cable in bulk spools dramatically reduces your cat 5 cable cost per foot – sometimes by half or more compared to smaller quantities. 1000-foot spools offer the best value for most commercial projects.

Economy spools cost the least but usually feature CCA conductors and basic jackets. Standard spools with pure copper conductors and CMR rating represent the best bang for your buck. Premium spools include specialized features like plenum rating or special jacket materials for outdoor installations.

Online wholesalers often beat local pricing on bulk spools, but shipping costs can add up quickly. A heavy spool might cost extra to ship, so factor that into your total project cost.

Pre-Made Cat 5 Patch Cable Prices by Length

Pre-made patch cables cost more per foot than bulk cable, but they save you time and labor on smaller projects.

Short patch cables offer the best value for connecting equipment in tight spaces. Medium-length cables bridge the gap between short patches and long runs. Long patch cables start competing with bulk cable on price, but they still save termination time.

The math gets interesting when you factor in labor costs. A technician might spend several minutes terminating each end of a bulk cable, while a patch cable plugs in immediately. For small projects, the labor savings often justify the higher material cost.

Factors That Drive Cat 5 Pricing Up or Down

When I help businesses understand cat 5 cable cost, several key factors can make prices swing dramatically.

The biggest price driver is copper versus CCA (Copper-Clad Aluminum). Pure copper costs significantly more, but provides excellent conductivity and won’t corrode over time. CCA uses aluminum cores with thin copper plating, which saves money upfront but can cause problems later.

Shielding options also impact your budget. Standard unshielded twisted pair (UTP) keeps costs down and works fine for most office environments. Foil shielding adds modest protection at a reasonable cost increase. Full braided shielding provides ultimate protection but comes with a premium price.

Jacket ratings represent another major cost factor. CMG (General use) cables cost the least but can only be used in basic applications. CMR (Riser) rated cables cost more due to improved fire resistance and are required for vertical runs between floors. CMP (Plenum) cables command the highest prices because they use special fire-resistant materials.

Brand markups can add substantial costs without always providing proportional value. While established manufacturers often deliver consistent quality and better warranties, generic suppliers frequently offer identical performance at lower prices.

Length & Gauge Matters

Cable length creates an interesting dynamic in cat 5 cable cost calculations. Longer cables require more material and cost more total dollars. However, the per-foot economics often improve with longer lengths since suppliers spread fixed costs across more cable.

AWG (American Wire Gauge) size significantly impacts both price and performance. 24 AWG represents the sweet spot for most installations – it balances cost and signal quality effectively. 22 AWG uses thicker conductors that reduce signal loss over long runs but increases costs. 26 AWG offers the lowest price but limits installation distances.

Signal loss increases with cable length, potentially requiring additional equipment like switches for runs approaching the 100-meter limit. This hidden cost can exceed your cable savings if you choose inadequate wire gauge.

From our experience installing thousands of cable runs across Massachusetts, we typically recommend 24 AWG for runs under 200 feet and upgrade to 22 AWG for longer distances.

Special Features That Add Cost

Several specialized features can increase cat 5 cable cost but provide specific benefits.

Snag-less boots prevent connector damage during installation and future moves. These molded strain relief boots add cost per cable end but dramatically reduce long-term maintenance expenses.

UL/ETL listings ensure cables meet electrical safety codes through third-party testing. Listed cables cost more than generic alternatives, but they’re required for commercial installations in most areas.

Outdoor and UV-resistant jackets use special polymer compounds that resist ultraviolet degradation and moisture damage. These environmental protections increase material costs substantially.

Plenum rating represents the most expensive jacket option due to fire-resistant materials that meet strict building codes. These cables cost significantly more than standard versions, but they’re non-negotiable for installations in air-handling spaces.

Cat 5 vs Cat 5e, Cat 6, Cat 6a – Is Upgrading Worth It?

When considering cat 5 cable cost, it’s tempting to stick with the cheapest option. But sometimes spending a little more upfront saves you headaches down the road.

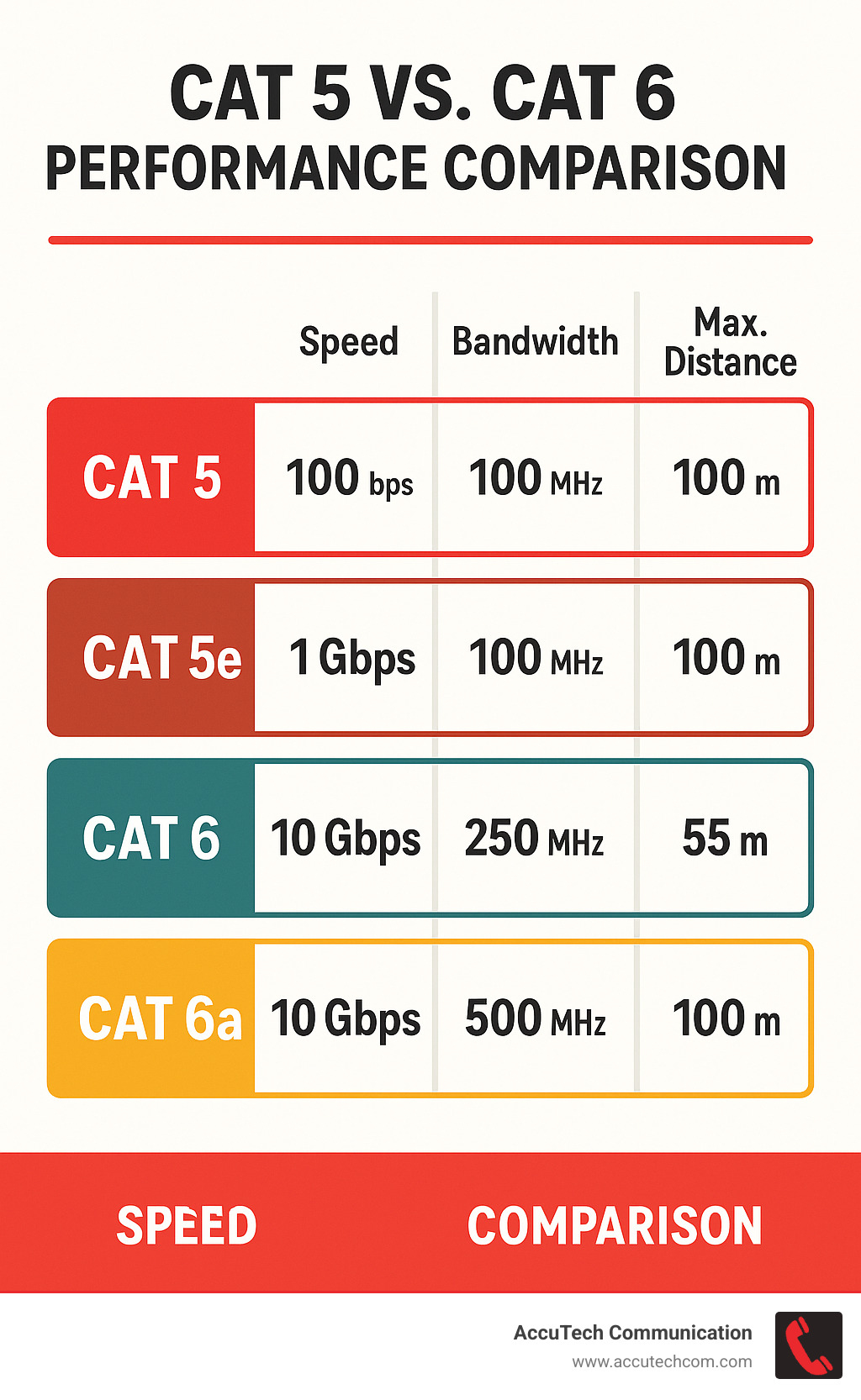

Cat 5e (the “e” stands for improved) supports gigabit speeds up to 1000 Mbps while maintaining that same 100 MHz bandwidth. The key improvement is reduced crosstalk between wire pairs.

Cat 6 steps things up significantly, delivering up to 10 Gbps over shorter distances (about 180 feet) and reliable 1 Gbps over the full 328-foot run. It operates at 250 MHz bandwidth.

Cat 6a (augmented) is the current sweet spot for future-proofing. It maintains that 10 Gbps speed over the full 328-foot distance at 500 MHz bandwidth.

Here’s what I’ve learned from 30+ years of installations across Massachusetts: the labor cost to pull cables through walls and ceilings is the same whether you’re installing Cat 5 or Cat6 CMR Ethernet Cable 1000ft. Since labor typically represents 60-70% of your total project cost, the cable upgrade often adds just 10-15% to your total budget.

Price Comparison Snapshot

The cat 5 cable cost advantage shrinks when you look at the bigger picture. Cat 5e typically costs about 10% more than standard Cat 5. Cat 6 runs 30-50% higher than Cat 5, while Cat 6a costs 70-100% more than Cat 5.

What’s interesting is how these price gaps have narrowed over the years. As Cat 5 becomes less common, manufacturers focus on newer categories, sometimes making Cat 5e and Cat 6 more competitively priced than you’d expect.

Performance-per-Dollar Analysis

This is where the cat 5 cable cost savings can actually cost you money later.

Gigabit readiness matters more than ever. Internet speeds keep climbing, and many businesses now have 200+ Mbps connections. Cat 5’s 100 Mbps limit becomes a bottleneck, while Cat 5e and higher categories handle these speeds easily.

PoE+ support is crucial for modern devices. Today’s wireless access points, IP cameras, and VoIP phones often need Power over Ethernet Plus, which delivers up to 25 watts. Cat 5 cables can struggle with this power delivery, especially over longer runs.

Resale value is something most people don’t consider. When you sell your building or lease space to new tenants, having modern cabling infrastructure adds real value.

The bottom line? For new installations, the small incremental cost for Cat 6 often makes sense. You get better performance, future-proofing, and peace of mind for just a modest increase in total project cost.

Smart Buying Tips & Hidden Costs

Smart cat 5 cable cost planning goes way beyond just looking at the cable price on the shelf. I’ve seen too many businesses get surprised by expenses they didn’t see coming.

The biggest money-saver is understanding bulk discounts. Most suppliers offer sweet spots at 500 feet, 1000 feet, and larger volumes. That single 1000-foot spool will cost you less per foot than buying several smaller spools.

Don’t forget about the tools you’ll need if you’re going the DIY route. Cable testers alone can run several hundred dollars. You’ll also need crimping tools, punch-down tools, and cable pulling equipment.

RJ45 connectors might seem like a small expense, but they add up when you’re doing multiple runs. Quality matters here too – cheap connectors can cause headaches with intermittent connections.

Shipping costs can be a real budget buster, especially for heavy cable spools. That great online deal might not look so great after you add shipping fees.

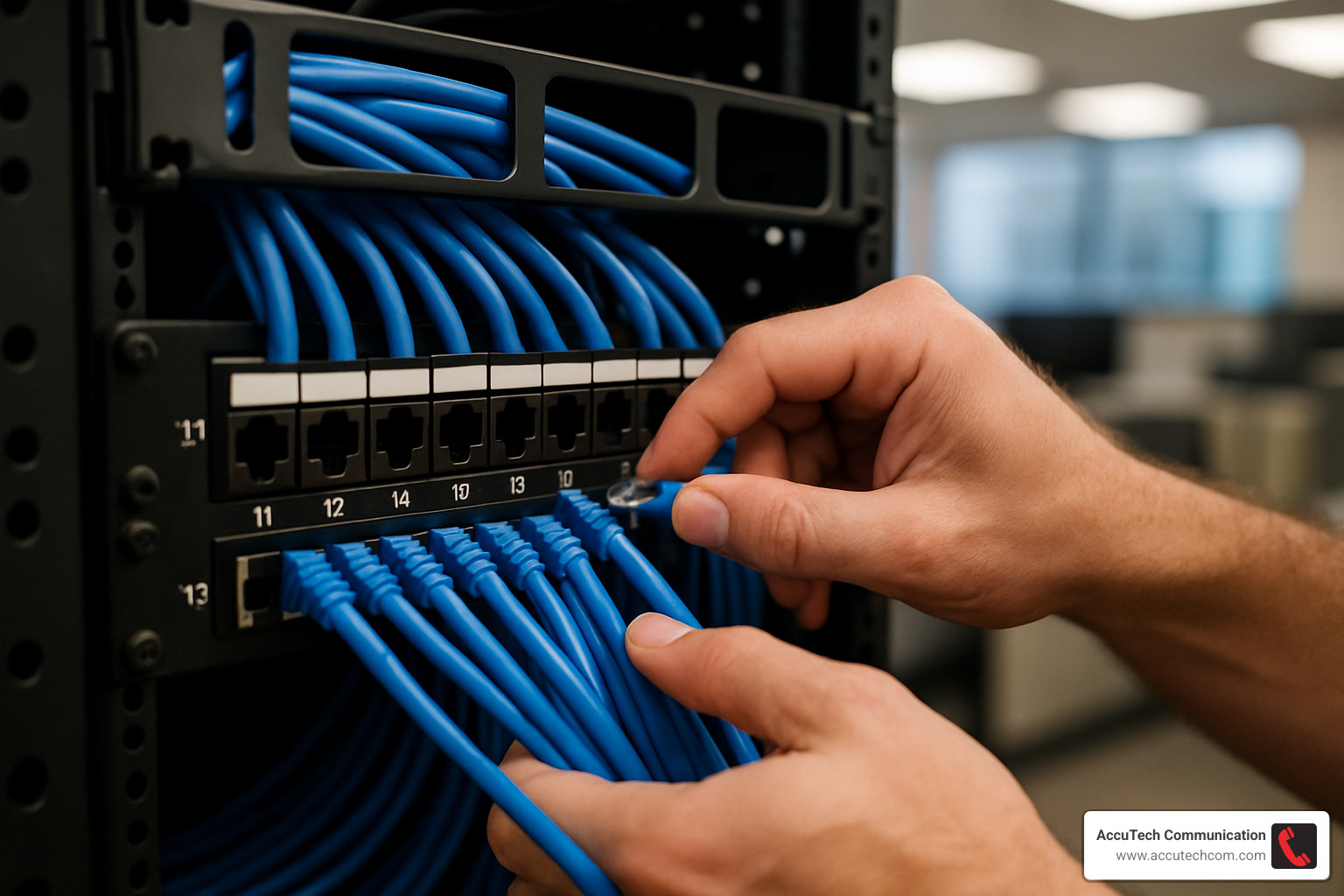

The biggest hidden cost is often installation labor. Professional installation typically costs more than the cable materials themselves.

How to Calculate Total Project Budget

Getting your cat 5 cable cost budget right means thinking about everything from start to finish. Start with your cable footage and add a waste factor – usually 10-15% covers the inevitable routing changes.

Your cable costs are just the foundation. From there, you need connectors on both ends, wall plates where they terminate, and possibly patch panel space.

Tools and equipment represent either a one-time investment for DIY projects or rental costs for specialized gear. If you’re only doing one project, renting often makes more sense than buying.

Labor costs vary widely depending on your market and installation complexity. Always add a contingency buffer – I recommend 10-20% for most projects.

When a Professional Install Saves Money

Professional installation often costs less in the long run than doing it yourself.

Testing equipment is expensive and essential. Professional cable testers cost thousands of dollars, but they catch problems that could require tearing out and redoing entire cable runs.

Certification matters more than most people realize, especially for business installations. Many commercial applications require certified installations with proper documentation.

Reduced downtime is huge for businesses. Our experienced teams complete installations faster and with fewer disruptions than DIY attempts.

We provide warranty coverage on both materials and workmanship. Code compliance is another area where professionals add value. Licensed installers know local requirements inside and out, preventing costly violations.

At AccuTech Communications, we regularly get calls from businesses who tried to save money on cat 5 cable cost by doing installations themselves. Unfortunately, the initial savings often disappear when troubleshooting time and re-work expenses get factored in.

Frequently Asked Questions About Cat 5 Cable Pricing

Is Cat 5 still worth buying in 2024?

This is probably the most common question I get from business owners looking at their cat 5 cable cost options. The honest answer? It depends on what you’re trying to accomplish.

Cat 5 still makes sense for legacy equipment replacement where you’re swapping out old cables that connect to devices that can’t handle faster speeds anyway. Basic VoIP phone systems are another sweet spot for Cat 5.

Here’s where I’d steer you away from Cat 5: any new business network installation. The price difference between Cat 5 and Cat 5e has gotten so small that it doesn’t make financial sense to limit yourself to 100 Mbps when you could have gigabit capability for just a few dollars more.

Will longer cables slow my network?

Yes, and this is where understanding cat 5 cable cost versus performance really matters. Cat 5’s 100-meter limit sounds like plenty of distance, but signal loss starts affecting performance well before you hit that maximum.

Signal loss increases gradually with distance, causing your network to work harder to maintain connections. You might not notice it immediately, but longer runs can cause increased error rates and connection instability.

The voltage drop issue becomes especially important if you’re using Power over Ethernet devices. A 250-foot Cat 5 run might deliver enough data signal but not enough power to keep an IP camera running reliably.

For runs approaching 300 feet, I typically recommend upgrading to 22 AWG cable instead of the standard 24 AWG, or stepping up to Cat 6 which handles longer distances much better.

Can I mix Cat 5 with newer cables?

Absolutely, and this comes up all the time during gradual network upgrades. The key thing to remember is that your network speed defaults to the slowest cable in the chain.

So if you’ve got beautiful new Cat 6 infrastructure throughout your building but connect everything with Cat 5 patch cables, you’re still limited to 100 Mbps speeds.

I always tell customers to document what cable types they have where because mixing categories during upgrades is totally normal. We’ve helped plenty of businesses phase in better cables over time rather than replacing everything at once.

Gigabit equipment automatically negotiates to work with whatever cable you’ve got, which is nice. Your switches and computers figure out the best speed they can achieve and work with that.

Conclusion

Making smart decisions about cat 5 cable cost goes way beyond just looking at sticker prices. After helping hundreds of businesses in Massachusetts, New Hampshire, and Rhode Island steer their cabling needs over the past 30 years, I’ve learned that the cheapest cable isn’t always the most economical choice.

The real story emerges when you factor in everything: installation labor, tools, connectors, and how well your network will serve you down the road. A seemingly expensive cable that prevents future headaches often delivers better value than a bargain option that leaves you scrambling for upgrades in two years.

Your biggest money-saving opportunities come from buying in bulk when possible, choosing pure copper conductors over cheaper alternatives, and getting professional installation right from the start. DIY looks tempting on paper, but we’ve rescued enough “weekend warrior” projects to know that doing it twice costs more than doing it right once.

Cat 5 still has its place in 2024, especially for legacy equipment replacement, budget-tight projects with basic speed needs, and applications that genuinely don’t need more than 100 Mbps. But if you’re planning new business networks or need future-proofing, it’s time to look at newer categories.

Here’s the thing about cat 5 cable cost – context matters enormously. What makes perfect sense for a small office replacing old phone lines might be completely wrong for a growing business planning to double their staff in three years.

At AccuTech Communications, we’ve watched technology evolve since 1993, and we’ve seen what works (and what definitely doesn’t). Our certified technicians don’t just install cables – we help you avoid the expensive mistakes that come from focusing only on upfront costs while ignoring long-term needs.

Getting your wires crossed – literally or figuratively – always costs more than getting it right the first time. Whether you need straightforward Cat 5 installation for specific applications or want to explore higher-performance options, we bring three decades of experience to every project.

Ready to make sense of your cabling options without breaking the budget? Learn more about our structured cabling services and find how we can help you steer the cable cost maze while building a network that actually serves your business goals.