Fiber Construction Guide: Top Tips & Insights for 2024

Connecting Tomorrow: Understanding Fiber Construction

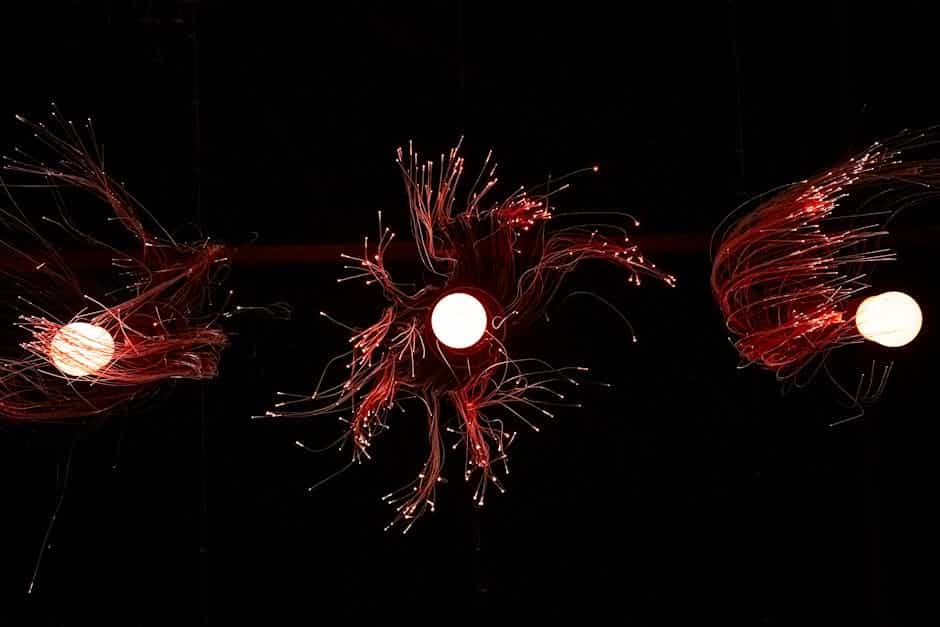

Fiber construction is the backbone of modern-day communication, revolutionizing how we interact, work, and play. This engineering marvel delivers high-capacity, low-latency internet by integrating underground cables, aerial fiber links, and even underwater routes. Here’s a quick look at what fiber construction entails:

- Overview: Creating pathways for fiber optic cables through various environments.

- Importance: Ensures stable, fast, and reliable internet connections for all.

- Fiber Optics: Uses light to transmit data over long distances quickly and efficiently.

Fiber networks are buried underground, strung between poles, or laid across the ocean floor. These networks aren’t just for homes; they support businesses, governments, and industries around the globe.

I’m Corin Dolan, owner of AccuTech Communications, with over two decades of experience in the industry. Over my career, I’ve helped design and implement fiber construction projects of all sizes. Together, let’s dive into the complexities and see why this technology is essential for modern communication.

Understanding Fiber Construction

What is Fiber Construction?

Fiber construction refers to the process of creating a network of fiber optic cables to transmit data using light signals. This involves laying cables underground, stringing them between poles, or even placing them underwater. The goal is to provide high-speed, reliable internet and communication services.

Optical telecommunications rely on these fiber optic networks to deliver data at lightning speeds over long distances. This technology forms the backbone of our digital infrastructure, supporting everything from streaming services to cloud computing.

Key Phases in Fiber Construction

Building a fiber network is a multi-step process that involves several key phases:

Field Data Collection

The first step is field data collection. Engineers gather information about the area where the fiber will be installed. This includes checking for existing utilities like water, gas, and electrical lines. Accurate data collection is crucial to avoid damaging existing infrastructure.

Make-Ready Engineering

Next is make-ready engineering. Engineers design a detailed plan for the fiber network, including where to place poles or underground conduits. This phase also involves getting permissions and permits from local authorities.

Example: In one project, engineers had to redesign their plan to avoid a newly finded gas line, which saved time and prevented potential hazards.

Mainline Splicing

Mainline splicing is where the magic happens. This involves connecting the main fiber cables to smaller, local networks. Splicing ensures that data can flow seamlessly from the main network to individual homes and businesses.

Fact: Splicing can take three to six weeks, depending on the complexity of the network.

Components of Fiber Construction

Fiber construction involves several key components:

- Underground Cables: These are buried 3-4 feet below the surface to protect them from damage.

- Aerial Fiber Links: These are strung between poles, ideal for uneven or rocky terrain.

- Conduit Placement: Plastic or steel tubes that protect and organize the fiber cables.

- Fiber Termination: The process of connecting the fiber cables to distribution hubs or patch panels.

Each component plays a crucial role in ensuring the network is robust and reliable.

Quote: “Deploying fiber cabling underground, over aerial links above ground, or using submarine cables to span the oceans requires a set of tools and practices collectively known as fiber construction.” – AccuTech Communications

Digital Infrastructure

Fiber construction is essential for our digital infrastructure. It supports everything from streaming video to telemedicine. Without it, our modern way of life would be much slower and less efficient.

In summary, fiber construction is a complex but essential process. It involves multiple phases and components, each playing a crucial role in creating a robust and reliable network. This technology is the backbone of our digital world, enabling fast and efficient communication and data transfer.

Next, let’s dig into the costs and duration of fiber construction.

Costs and Duration of Fiber Construction

How Much Does Fiber Construction Cost?

Building a fiber optic network is a significant investment. The costs can vary widely based on several factors, such as whether the cables are installed underground or overhead, the terrain, and the length of the circuit.

Underground Costs: Underground fiber construction is typically more expensive. It can cost up to $60,000 per mile. The high costs are mainly due to the labor-intensive process of trench digging, laying conduit, and pulling fiber through it. Labor can account for up to 60% of the total cost.

Aerial Costs: Aerial fiber construction, where cables are strung between utility poles, is generally cheaper. However, it still involves costs for make-ready engineering and construction to ensure the poles can support the new cables. This process can also be time-consuming, adding to the overall expense.

Cost Comparison:

– Underground Deployment: Up to $60,000 per mile

– Aerial Deployment: Generally lower, but varies based on pole and terrain conditions

How Long Does Fiber Construction Take?

The timeline for fiber construction can range from six to twelve months, depending on various factors such as the length of the circuit, terrain, and weather conditions. Let’s break down the typical phases and their durations:

Field Data Collection:

– Duration: 2-4 weeks

– Activities: Engineers gather information about the area and existing utilities.

Make-Ready Engineering:

– Duration: 2-4 weeks

– Activities: Engineers design the network layout and secure necessary permits.

Make-Ready Construction:

– Duration: 4-12 weeks

– Activities: Preparing poles or digging trenches to make space for the fiber cables.

Fiber Construction:

– Duration: 4-8 weeks

– Activities: Laying the fiber cables, either underground or overhead.

Mainline Splicing:

– Duration: 3-6 weeks

– Activities: Connecting main fiber cables to local networks.

Service Drop Construction:

– Duration: 2-4 weeks

– Activities: Extending fiber from the main line to homes or businesses.

Drop Splicing:

– Duration: 2-4 weeks

– Activities: Splicing the drop lines to the main network.

Installation:

– Duration: Varies

– Activities: Installing equipment at homes or businesses and activating the service.

Delays: Weather conditions, such as extreme temperatures, rain, snow, and high winds, can cause delays at any phase. Planning for these contingencies is crucial to stay on schedule.

In summary, the cost and duration of fiber construction depend on numerous factors, including whether the deployment is underground or aerial, the complexity of the terrain, and weather conditions. Proper planning and efficient project management can help mitigate some of these challenges.

Next, let’s explore the technological advancements in fiber construction.

Technological Advancements in Fiber Construction

Cutting-Edge Technologies

Fiber construction has come a long way, thanks to innovations in technology. These advancements have made the process faster, cheaper, and more accessible. Let’s explore some of the cutting-edge technologies that are revolutionizing the field.

Microtrenching: This technique involves creating narrow, shallow trenches (8”-16” deep) to lay fiber cables. Microtrenching minimizes the disruption to existing infrastructure and natural habitats. It’s particularly useful in urban areas where space is limited, and traditional trenching would be too invasive.

Directional Drilling: This method allows for the installation of underground cables without extensive digging. By using a guided drill, workers can steer around obstacles like existing utilities and natural barriers. This not only speeds up the process but also reduces the cost and environmental impact.

LIDAR (Light Detection and Ranging): LIDAR technology uses laser pulses to create high-resolution maps of the terrain. This helps in planning the most efficient routes for fiber installation. By accurately mapping out the area, LIDAR reduces the need for manual surveys, saving both time and money.

Impact of New Technologies

The introduction of these advanced techniques and equipment has significantly impacted the fiber construction industry. Here’s how:

Speed: Automation and new technologies have drastically reduced the time it takes to complete fiber construction projects. For example, using automated processes for network design can cut the time needed by up to 30%. Similarly, digital twin models and computer vision can speed up site surveys by 20-25%.

Cost Reduction: By minimizing manual labor and reducing the need for extensive digging, these technologies lower the overall costs of fiber construction. Automated permit systems can also streamline the approval process, cutting the time needed to acquire permits by up to 15%.

Accessibility: Advanced techniques like microtrenching and directional drilling make it easier to install fiber in previously challenging environments. Whether it’s a densely populated urban area or a remote rural location, these technologies ensure that fiber networks can be deployed more efficiently and with less disruption.

In summary, technological advancements in fiber construction are making the process faster, cheaper, and more accessible. These innovations are crucial for meeting the growing demand for high-speed internet and other fiber-based services.

Next, let’s look at the various applications of fiber construction in residential, commercial, and industrial settings.

Fiber Construction for Various Applications

Residential Fiber Construction

Fiber to the Home (FTTH) is revolutionizing residential internet access. FTTH involves installing optical fiber directly to homes, resulting in significantly faster and more reliable internet connections.

Benefits of FTTH:

– Higher Speeds: FTTH offers speeds up to 100 Mbps, which is 20 to 100 times faster than traditional cable or DSL connections.

– Better Performance: Fiber connections are more stable and less prone to interference, ensuring a smoother online experience for streaming, gaming, and video calls.

– Future-Proof: Upgrades to the network infrastructure can be done without replacing the fiber itself, making it a long-term solution.

Installation Process:

– Planning: Engineers design a detailed plan for bringing fiber to a neighborhood.

– Construction: Fiber is either buried underground or strung on utility poles.

– Connection: The fiber is spliced and tested to ensure it’s working perfectly before connecting it to homes.

Commercial and Industrial Uses

Fiber construction isn’t just for homes. Businesses and industries benefit significantly from fiber networks.

Commercial Applications:

– Networking: Fiber optic networks provide higher bandwidth and faster speeds, essential for businesses that rely on cloud services, large data transfers, and video conferencing.

– Cost Savings: Businesses save money in the long run due to increased productivity and fewer network outages.

– Better Customer Service: Faster internet speeds lead to better customer experiences, whether through quicker transaction times or improved online services.

Industrial Applications:

– Medical: Hospitals and clinics need reliable, high-speed internet for telemedicine, electronic health records, and real-time medical imaging.

– Government: Fiber optics are used in SONAR, as well as for wiring machinery and vehicles that require precision and no interference. Programs like the Rural Digital Opportunity Fund (RDOF) are injecting billions into rural broadband networks.

– Manufacturing: Factories use fiber networks for real-time monitoring and automation, improving efficiency and reducing downtime.

Fiber construction for commercial and industrial applications follows a similar process to residential installations but often involves more complex planning and specialized equipment. The benefits, however, are equally transformative, providing the backbone for modern digital infrastructure.

Next, let’s explore the challenges and solutions in fiber construction.

Challenges and Solutions in Fiber Construction

Fiber construction is a complex process that faces several challenges. However, with strategic solutions, these problems can be effectively managed.

Common Challenges

Permitting Delays

Obtaining permits is one of the most time-consuming parts of fiber construction. It can take weeks or even months to secure the necessary approvals from local authorities and utilities. Poor management can further delay this process.

Harsh Weather

Weather conditions like extreme temperatures, rain, snow, and high winds can create unpredictable challenges. These conditions can be hazardous to both the fiber infrastructure and the construction personnel.

Difficult Terrain

The path chosen for fiber construction can significantly impact costs and complexity. Traversing mountains, waterways, or urban areas adds layers of difficulty. Right-of-way and permitting expenses also vary depending on the chosen path.

Strategic Solutions

Proactive planning is crucial. Automated processes can help generate optimal routes and node locations based on topographical data and existing infrastructure. This reduces time and errors, making the construction process smoother.

Advanced Equipment

Using cutting-edge technologies like microtrenching, directional drilling, and LIDAR can speed up the construction process and reduce costs. For example, LIDAR can create high-resolution 3D maps, helping to identify obstacles and plan routes more efficiently.

Skilled Labor

Having top-trained field supervisors and technicians is essential. Skilled labor can effectively manage complex tasks like trench digging, splicing, and testing. This helps in reducing rework and ensures the project stays within budget.

Streamlined Permitting

Establishing a standardized, automated permit center can expedite the permitting process. Such a center can understand regional permit requirements, collect and validate necessary data, create and submit permits, and track their progress in real time. This can boost application approval rates by 10 to 20 percent and cut the time needed to acquire permits by as much as 15 percent.

Weather-Resistant Materials

Selecting weather-resistant materials and incorporating redundancy in network planning can ensure that the fiber network remains operational even in extreme weather conditions. Regular maintenance and fiber monitoring are also essential to maintain reliability.

By addressing these challenges with strategic solutions, fiber construction can be more efficient and cost-effective.

Next, let’s answer some frequently asked questions about fiber construction.

Frequently Asked Questions about Fiber Construction

What is the most time-consuming part of fiber construction?

The most time-consuming part of fiber construction is often obtaining permits. Securing the necessary approvals from local authorities and utilities can take weeks or even months. Delays can occur due to poor management or stringent regulations.

Another time-consuming phase is the make-ready engineering step. This involves creating construction plans and ensuring all necessary modifications are made to existing infrastructure, such as utility poles. This phase can take between two to four weeks, depending on the complexity and size of the service area.

How can the cost of fiber construction be minimized?

Minimizing the cost of fiber construction involves several strategies:

- Efficient Labor Management: Labor is the largest expense, accounting for up to 60% of the overall project cost. Using skilled labor can reduce rework and ensure tasks are completed efficiently.

- Advanced Equipment: Utilizing technologies like microtrenching and directional drilling can speed up the process and reduce labor costs. For example, microtrenching creates smaller, less invasive trenches, which can be quicker and cheaper to dig and restore.

- Optimized Route Planning: Automated tools and LIDAR can help in creating optimal routes that avoid difficult terrain and reduce the need for extensive digging or aerial work. This minimizes both labor and material costs.

- Bulk Material Purchasing: Buying materials like fiber cables in bulk can reduce costs. Additionally, choosing weather-resistant materials can save money in the long run by reducing maintenance needs.

- Standardized Permitting: Streamlining the permitting process with a standardized, automated permit center can cut the time and costs associated with obtaining approvals.

What are the long-term benefits of investing in fiber construction?

Investing in fiber construction offers several long-term benefits:

- Higher Internet Speeds: Fiber optics provide faster and more reliable internet speeds compared to traditional copper networks. This leads to improved customer satisfaction and increased productivity.

- More Reliable Internet: Fiber optic cables are more resistant to weather conditions and electrical interference, ensuring a stable connection even during extreme weather.

- Better Bandwidth: Fiber networks offer higher bandwidth limits, making it easier to share files, use cloud applications, and stream content without slowdowns.

- Less Latency: Fiber optic internet reduces latency issues, providing smoother and faster data processing.

- Long-Term Cost Savings: Although the initial investment is high, the long-term benefits include greater employee productivity and customer satisfaction, leading to a better bottom line. Fiber networks also require less maintenance, reducing ongoing costs.

- Future-Proofing: As more business tools move to the cloud and demand for high-speed internet increases, fiber optics will ensure that your infrastructure can handle future technological advancements.

By understanding the complexities and benefits of fiber construction, you can make informed decisions that will improve your business’s connectivity and efficiency. Next, we will explore the technological advancements in fiber construction.

Conclusion

Future Prospects

The future of fiber construction is bright. As demand for high-speed internet and reliable connectivity grows, fiber networks will become even more essential. Emerging technologies like 5G and the Internet of Things (IoT) will drive the need for robust fiber infrastructure, making it a critical investment for both urban and rural areas.

AccuTech Communications

At AccuTech Communications, we are committed to staying ahead of these trends. Our team continuously explores new methods and technologies to improve the efficiency and effectiveness of our fiber construction projects. We understand that the landscape of telecommunications is changing, and we are dedicated to providing solutions that not only meet current demands but also anticipate future needs.

Reliable Service, Competitive Pricing, Commitment to Quality

Reliable Service: With over two decades of experience, AccuTech Communications has built a reputation for reliability. Our skilled technicians and engineers ensure that every project is completed to the highest standards. We use state-of-the-art equipment and methodologies to deliver consistent, dependable results.

Competitive Pricing: We believe that high-quality fiber construction should be accessible to all businesses. That’s why we offer competitive pricing without compromising on quality. Our efficient project management and bulk purchasing strategies help us keep costs down, providing excellent value for our clients.

Commitment to Quality: Quality is at the heart of everything we do. From initial consultation to final installation, we adhere to stringent quality control measures. Our comprehensive testing and certification processes ensure that every fiber network we build performs optimally and meets industry standards.

By choosing AccuTech Communications, you are investing in a partner that prioritizes your needs and delivers exceptional results. Whether you are looking to upgrade your existing network or start on a new fiber construction project, we are here to help you steer the complexities with ease and expertise.

Ready to improve your connectivity? Contact us today to discuss your fiber construction needs and find how we can help you build a future-proof network.