Fiber Optic Technology: 10 Powerful Benefits in 2025

Understanding the Light-Powered Data Revolution

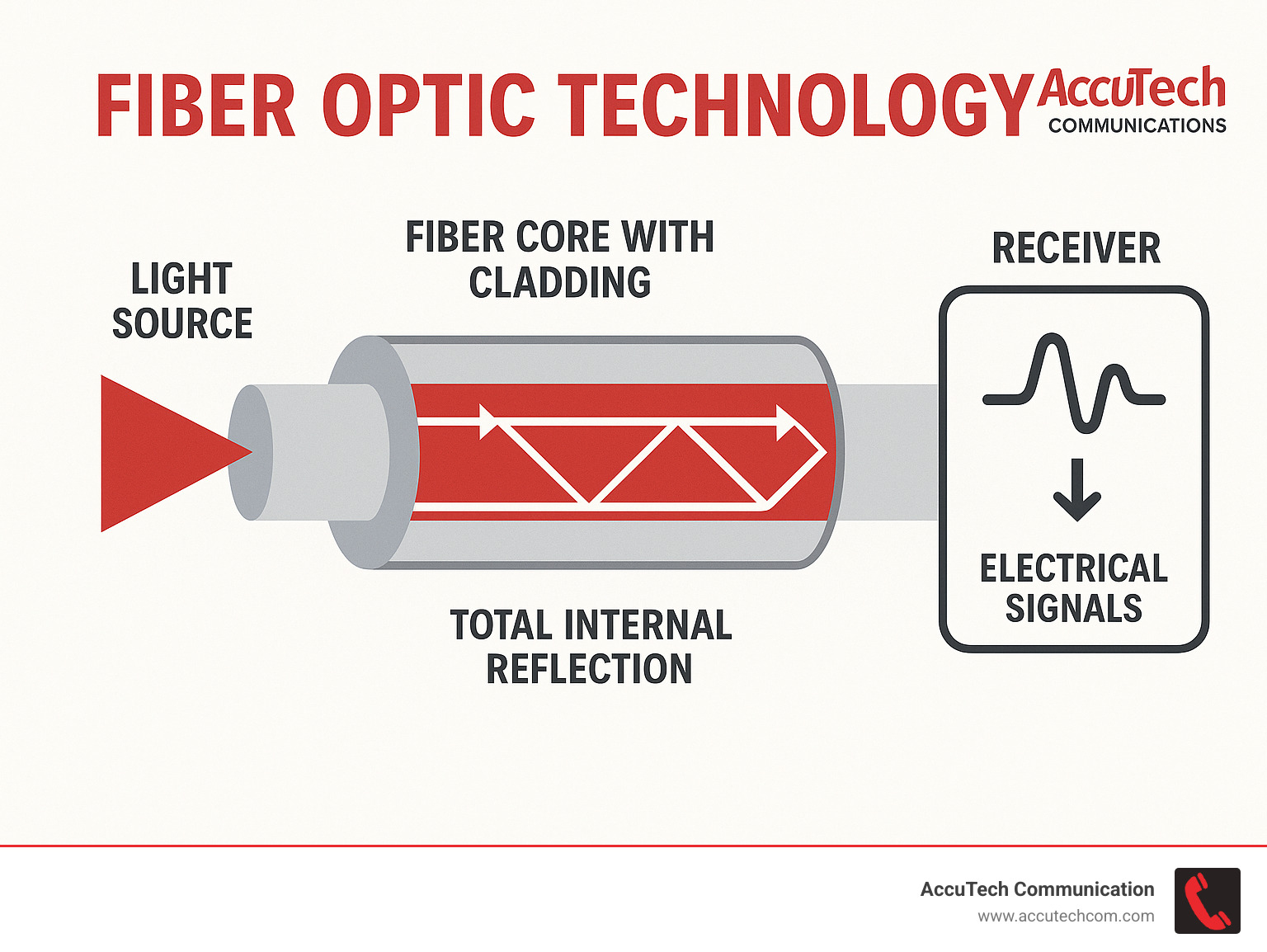

Fiber optic technology is a communication system that transmits data as pulses of light through thin strands of ultra-pure glass or plastic. This technology forms the backbone of modern internet, telecommunications, and data networks worldwide.

Key Facts About Fiber Optic Technology:

- Data Speed: Can transmit data at rates up to 800 Gbps in today’s data centers

- Distance: Carries signals up to 100 kilometers without a repeater (compared to 100 meters for copper)

- Material: Made of glass cores thinner than human hair (9 μm for single-mode fiber)

- Signal Method: Uses light pulses rather than electrical signals

- Benefits: Immune to electromagnetic interference, higher bandwidth, more secure

Fiber optics works through a principle called total internal reflection, where light pulses bounce along the core-cladding boundary of the fiber, traveling at about 70% the speed of light in glass. This enables the transmission of massive amounts of data over long distances with minimal signal loss.

As the world has grown more connected and data consumption has increased exponentially, fiber optic technology has become increasingly important for businesses seeking reliable, high-speed connectivity solutions.

I’m Corin Dolan, owner of AccuTech Communications with over 30 years of experience implementing fiber optic technology solutions for businesses across New England. My team has helped countless organizations transition from outdated copper infrastructure to modern fiber optic technology systems that support their growing bandwidth demands.

Key Fiber Optic Technology vocabulary:

– fiber optic cable technology

– fiber optic monitoring system

– fiber optic technology history

How Fiber Optic Technology Works

Ever wonder how your favorite Netflix show travels from a data center miles away to your living room TV? Fiber optic technology makes this possible through an almost magical process that turns your data into light and sends it racing through glass strands thinner than a human hair.

Physics of Light Guidance

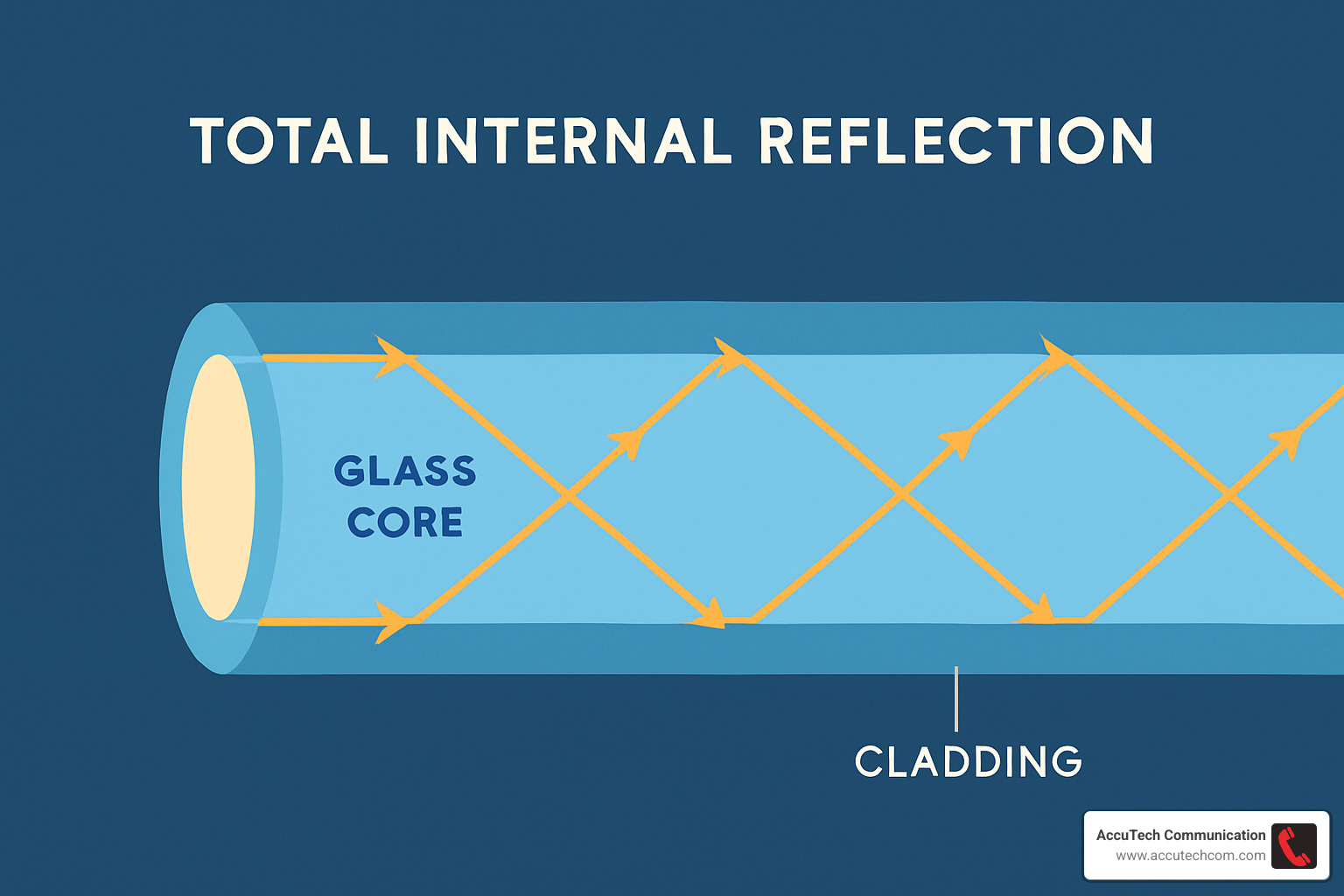

At its core, fiber optic technology relies on a fascinating principle called total internal reflection. Think of it like a mirror tunnel that keeps light bouncing forward without escaping. When light travels from a dense material (the glass core) toward a less dense material (the cladding), something interesting happens at the boundary.

If the light hits this boundary at an angle greater than what scientists call the “critical angle,” it can’t pass through—instead, it reflects back completely into the core. This is total internal reflection in action, and it’s governed by Snell’s Law, which describes how light bends when moving between materials with different refractive indices.

The fiber’s design creates a perfect light highway where signals can travel enormous distances with minimal loss. Each fiber has what’s called a numerical aperture—essentially the range of angles at which light can enter and still be guided through the fiber.

While we often explain this using ray theory (imagining light as straight lines bouncing at angles), light actually behaves as both particles (photons) and waves. For extremely thin single-mode fibers, wave theory provides a more accurate picture of how signals truly move through the glass.

For a deeper dive into the physics, Scientific research on total internal reflection offers fascinating details about this phenomenon.

Components of a Fiber Optic Cable

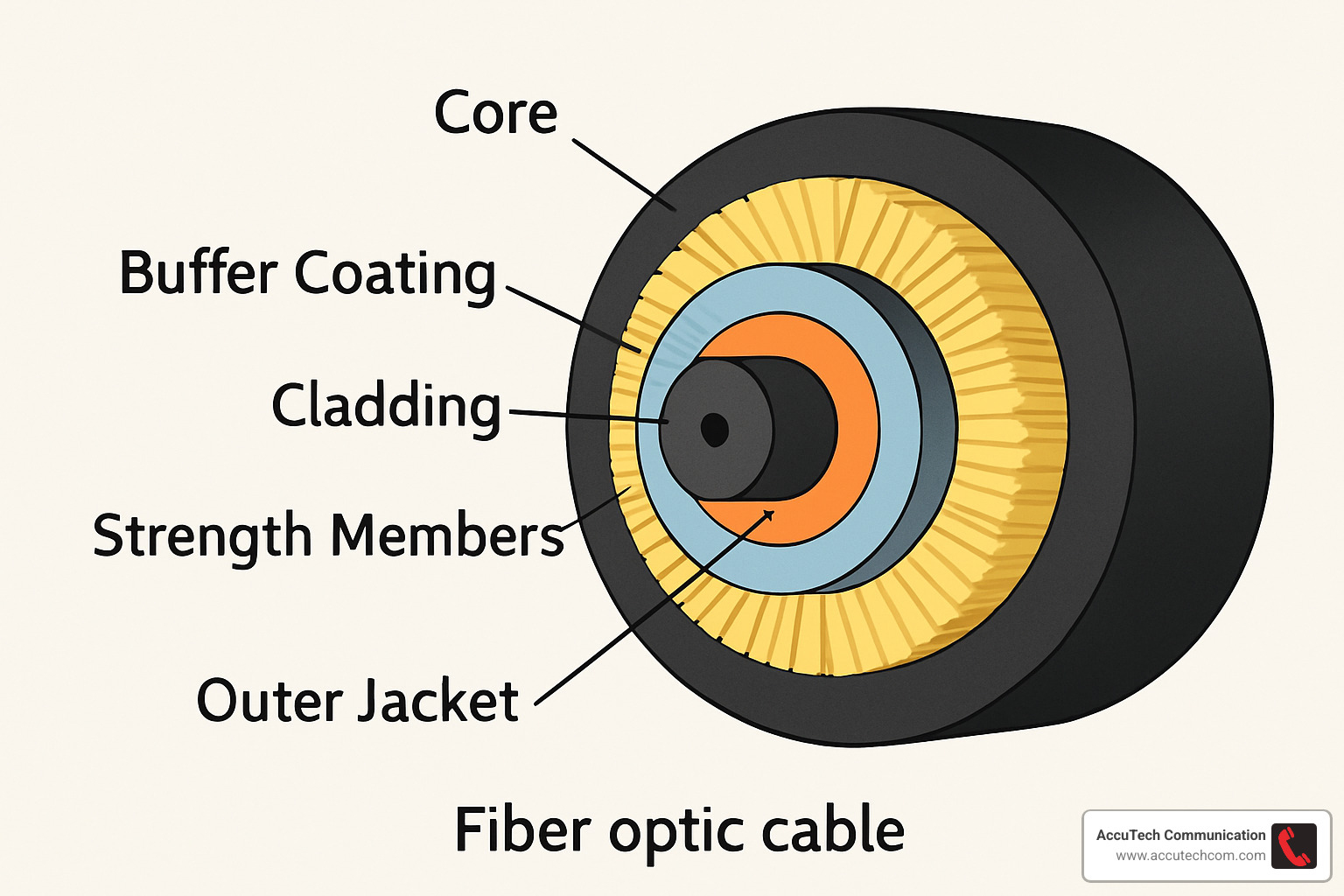

A fiber optic cable isn’t just a simple glass strand—it’s an engineering marvel with multiple protective layers working together.

At the center lies the core, the highway where light travels. Made of ultra-pure silica glass, it’s incredibly thin—just 9 micrometers across for single-mode fiber (about 1/10 the width of a human hair) or 50-62.5 micrometers for multimode fiber.

Surrounding this is the cladding, a glass layer with a slightly different composition that creates the critical refractive index difference. The standard cladding diameter is 125 micrometers, regardless of core size.

Next comes the buffer coating, typically made of plastic, which provides the first line of defense against moisture and physical damage.

The strength members (usually Kevlar fibers) add crucial tensile strength—the same material used in bulletproof vests! These yellow fibers prevent the cable from stretching during installation, which would damage the delicate glass core.

Finally, the outer jacket provides the final layer of protection. Often made of PVC or other durable materials, it’s designed to withstand the specific environment where the cable will be installed—whether that’s underground, underwater, or exposed to the elements.

This sophisticated layering is why fiber optic cables can survive harsh conditions for decades without degradation. The glass itself doesn’t corrode, and the protective layers shield it from almost anything nature throws at it.

Data Encoding and Transmission in Fibers

So how does your email, video call, or TikTok actually travel through these glass strands? It all starts with conversion.

Your digital data (in electrical form) reaches a transmitter containing either a laser (for single-mode fiber) or an LED (for multimode fiber). This device converts electrical signals into pulses of light, flashing on and off billions of times per second to represent the 1s and 0s of binary data.

These light pulses zoom through the fiber at approximately 70% the speed of light in a vacuum—about 200,000 kilometers per second. While this is slightly slower than light in a vacuum (300,000 km/s), it’s still mind-bogglingly fast! Your data could circle the Earth 5 times in just one second.

For longer distances, the signal gradually weakens (attenuation) and spreads out (dispersion). To combat this, networks use repeaters or amplifiers placed at intervals to boost the signal. Modern optical amplifiers can strengthen the light directly without converting it back to electricity first.

To squeeze even more data through a single fiber, engineers use a clever technique called Wavelength Division Multiplexing (WDM). This is like adding more lanes to a highway—multiple light signals of different wavelengths (colors) travel simultaneously through the same fiber without interfering with each other. Dense WDM systems can carry 80+ separate wavelength channels on a single fiber, dramatically multiplying capacity.

At AccuTech Communications, we’ve seen how fiber optic technology has revolutionized business connectivity across New England. The principles may sound complex, but the result is simple: faster, more reliable data transmission that keeps your business moving at the speed of light.

Types of Fiber Optic Cables and Key Specifications

When it comes to Fiber Optic Technology, not all glass strands are created equal. Just like you wouldn’t use the same type of vehicle for a cross-country road trip and a quick grocery store run, different fiber types serve different networking needs.

Single-Mode vs. Multimode Performance

The fiber optic world has two main families: single-mode and multimode fiber. Think of single-mode as a one-lane highway where light travels in a straight, direct path, while multimode is more like a multi-lane freeway with light bouncing along several different routes.

| Characteristic | Single-Mode Fiber | Multimode Fiber |

|---|---|---|

| Core diameter | 8-10 μm | 50 or 62.5 μm |

| Light source | Laser | LED (typically) |

| Distance capability | Up to 100+ km | Up to 300-600 m |

| Bandwidth | Higher | Lower |

| Cost | Higher (electronics) | Lower (electronics) |

| Applications | Long-haul, telecom | Data centers, LANs |

| Modal dispersion | None | Yes |

Single-mode fiber features a tiny core about the width of a human red blood cell (9 μm). This narrow path forces light to travel in just one mode, eliminating signal distortion over distance. This makes it perfect for connecting buildings across town or linking cities together. While the fiber itself isn’t necessarily more expensive, the laser light sources needed for single-mode systems typically cost more than their multimode counterparts.

Multimode fiber, with its wider core (typically 50 or 62.5 μm), allows light to travel in multiple paths simultaneously. This makes it easier to connect to light sources but creates a trade-off: those multiple paths cause the signal to spread out over distance (called modal dispersion), limiting how far data can travel. For shorter connections within a building or campus, multimode is often the cost-effective choice.

Modern multimode fibers come in different “flavors” – OM1 through OM5 – with each new generation offering better performance. Today’s data centers typically use OM3 or OM4 laser-optimized multimode fiber to support their high-speed connections.

Special-Purpose & Emerging Fibers

Beyond these everyday workhorses, Fiber Optic Technology includes some fascinating specialists designed for unique applications:

Polarization-maintaining fiber does exactly what its name suggests – it keeps light waves aligned in a specific orientation. This might seem like a small detail, but it’s crucial for scientific instruments, certain types of sensors, and advanced communication systems.

Photonic-crystal fiber looks like something from a sci-fi movie under a microscope, with tiny air holes running through it in precise patterns. These microstructured fibers can control light in ways traditional fibers can’t, making them valuable for specialized research and sensing applications.

Plastic optical fiber trades glass for plastic, sacrificing some performance for practicality. While it can’t transmit light as efficiently as glass, it’s more flexible, harder to break, and easier to install – perfect for short runs in automobiles, home networks, or medical devices.

Hollow-core fiber represents a fascinating breakthrough where light actually travels through air rather than glass. Since light moves faster in air than in glass, these fibers could potentially reduce latency for applications where every microsecond matters, like high-frequency trading or certain military communications.

Composite fiber cables bring power and data together, combining optical fibers with copper conductors in a single cable. This clever design can reduce installation costs and pathway congestion by over 80%.

Multicore fiber packs multiple cores into a single strand, dramatically multiplying capacity. The results can be astonishing – in 2023, researchers achieved a mind-boggling 22.9 petabits per second over a single multi-core fiber. To put that in perspective, that’s enough bandwidth to handle about 100 million video calls simultaneously!

As bandwidth demands continue to grow, these specialized fibers are moving from research labs into real-world networks, constantly pushing the boundaries of what Fiber Optic Technology can achieve.

Advantages, Challenges, and Real-World Applications

Fiber optic technology has transformed how we connect our world, offering remarkable benefits over traditional copper wiring. But like any technology, it comes with its own set of challenges that need thoughtful solutions.

Telecom & Internet Backbone Powerhouse

When you stream your favorite show or join a video call, chances are your data is traveling through miles of glass fiber. There’s a good reason for this – fiber optic technology simply outperforms the alternatives in several crucial ways.

The bandwidth capacity of fiber is truly extraordinary. A single strand can carry multiple terabits per second, making copper cables look like narrow country lanes next to a superhighway. This massive capacity handles our growing appetite for data-hungry applications from 4K streaming to cloud computing without breaking a sweat.

Distance is another area where fiber shines brilliantly. While copper signals fade after about 100 meters, fiber happily carries data up to 100 kilometers without needing a boost. This long-distance capability has literally connected our world, spanning oceans and continents.

Perhaps most impressive is fiber’s future-readiness. As our bandwidth needs grow (and they always do), existing fiber infrastructure often needs just equipment upgrades at each end rather than replacing the cables themselves. It’s like getting a faster car without needing to rebuild the entire highway.

These advantages have made fiber the backbone of our connected world through:

- FTTX deployments bringing blazing speeds directly to homes and businesses

- Data centers where every millisecond and megabit matters

- Submarine cables forming an underwater web of approximately 436 cables stretching 1.3 million kilometers around our planet

- DWDM networks that multiply capacity by sending multiple light wavelengths through a single fiber, like adding more lanes to our data highway

The Ethernet Alliance roadmap shows just how rapidly fiber technologies continue to evolve, with 400G and 800G speeds becoming reality and terabit connections on the horizon.

Medical, Industrial & Military Frontiers

Fiber optic technology isn’t just connecting our computers – it’s saving lives, powering industry, and strengthening national security.

In hospitals across New England, surgeons perform delicate procedures using endoscopes with fiber optic bundles thinner than a strand of spaghetti. These tiny glass highways carry light in and images out, making minimally invasive surgeries possible. Fiber optic sensors can even monitor vital signs from inside the body, providing crucial real-time feedback during procedures.

On factory floors, fiber thrives where electronic sensors would surrender. Immune to electromagnetic interference and resistant to harsh chemicals, fiber optic sensors monitor everything from the temperature of molten metal to the subtle vibrations that might signal a failing wind turbine gearbox before catastrophic failure.

Our water infrastructure is getting smarter too, with fiber networks connecting meters and sensors that spot leaks, check water quality, and optimize distribution. These systems can save billions of gallons annually – particularly important in regions facing water challenges.

Military applications leverage fiber’s natural security advantages. Since fiber doesn’t radiate signals that can be intercepted, and isn’t affected by electromagnetic interference, it’s perfect for secure communications. Fiber optic gyroscopes provide precise navigation for aircraft and missiles without any moving parts to wear out or fail.

Limitations & Mitigation Strategies

Despite its superpowers, fiber optic technology isn’t without challenges. The good news? For every challenge, smart solutions have emerged.

The higher initial cost of fiber installation compared to copper has traditionally been a barrier. However, this gap continues to narrow, and when you consider the long-term benefits and reduced maintenance, fiber often proves to be the more economical choice over time.

The fragility of glass fibers presents another challenge. These tiny strands can break if bent too sharply or pulled too forcefully during installation. This is why proper installation by certified technicians is so important – something we at AccuTech take very seriously.

Speaking of installation, fiber requires specialized skills and equipment for proper splicing and termination. The precision required is measured in microns – far smaller than the width of a human hair. This expertise isn’t something you can improvise; it requires proper training and experience.

Traditional fibers also suffer from bend sensitivity – try to route them through tight spaces or sharp corners, and signal loss becomes a serious problem.

Fortunately, these challenges have sparked innovative solutions:

Bend-insensitive fiber (meeting the G.657 standard) can steer tight corners with minimal signal loss, making installation in crowded spaces much more forgiving. Pre-terminated assemblies reduce the need for field termination, simplifying installation dramatically. For harsh environments, ruggedized designs protect the delicate glass, whether on factory floors or battlefields. And air-blown fiber systems allow for future-proofing by installing empty microducts initially and adding fibers as needed.

These advances have made fiber optic technology more practical and accessible than ever before, bringing its benefits within reach for organizations of all sizes – from small businesses to large enterprises across Massachusetts, New Hampshire, and Rhode Island.

Installation, Testing, and Maintenance Essentials

Let’s face it – even the most advanced Fiber Optic Technology is only as good as its installation. I’ve seen perfectly good fiber systems fail simply because someone skipped a few critical steps during setup. The good news? With the right approach, your fiber network can deliver flawless performance for decades.

Installing Fiber the Right Way

Think of fiber installation like building a highway for light – the path matters tremendously. Start with careful pathway planning that considers not just today’s needs but tomorrow’s access requirements. I always tell clients to imagine someone needing to service that cable five years from now – will they curse your name or thank you?

When selecting cables, you’ll typically choose between loose-tube cables (the outdoor champions that handle temperature swings beautifully) and tight-buffered cables (indoor warriors with extra protection for busy environments). Your environment should dictate this choice – not just what’s on sale that week!

The actual installation requires a gentle touch. Fiber Optic Technology might seem robust, but exceeding the cable’s tension rating during pulling is like stretching a rubber band too far – it never quite returns to normal. Always maintain proper bend radius control (typically 10-15 times the cable diameter during installation). Those tiny glass strands don’t appreciate sharp corners!

For buildings with uncertain future needs, air-blown fiber systems are worth considering. These clever systems use compressed air to float fiber through pre-installed microducts – almost like a fiber water slide! This approach makes future upgrades much less disruptive since you won’t need to open walls or ceilings again.

For more detailed guidance on professional installation approaches, check out More info about Fiber Optic Installation.

Termination, Splicing & Testing

Once your fiber is installed, you’re faced with an important choice: how to connect everything together.

Fusion splicing is the gold standard – using an electric arc to literally melt and fuse two fiber ends together. The result? A nearly perfect connection with minimal light loss (typically just 0.01-0.1 dB). It’s like welding, but for tiny glass strands. While the equipment is expensive, the results speak for themselves.

Mechanical splicing is the quicker alternative, physically aligning fiber ends with index-matching gel. It’s faster and requires less specialized equipment, but typically introduces more signal loss (0.1-0.5 dB). Think of it as using glue instead of welding – sometimes perfectly appropriate, but not always the strongest solution.

For connections that need to be unplugged occasionally, you’ll need connectors. The connector landscape includes trusty SC connectors (push-pull with a 2.5mm ferrule), compact LC connectors (smaller 1.25mm ferrule perfect for tight spaces), legacy ST connectors (the bayonet-style ones that twist to lock), and high-density MPO/MTP connectors that can handle up to 72 fibers in one connection!

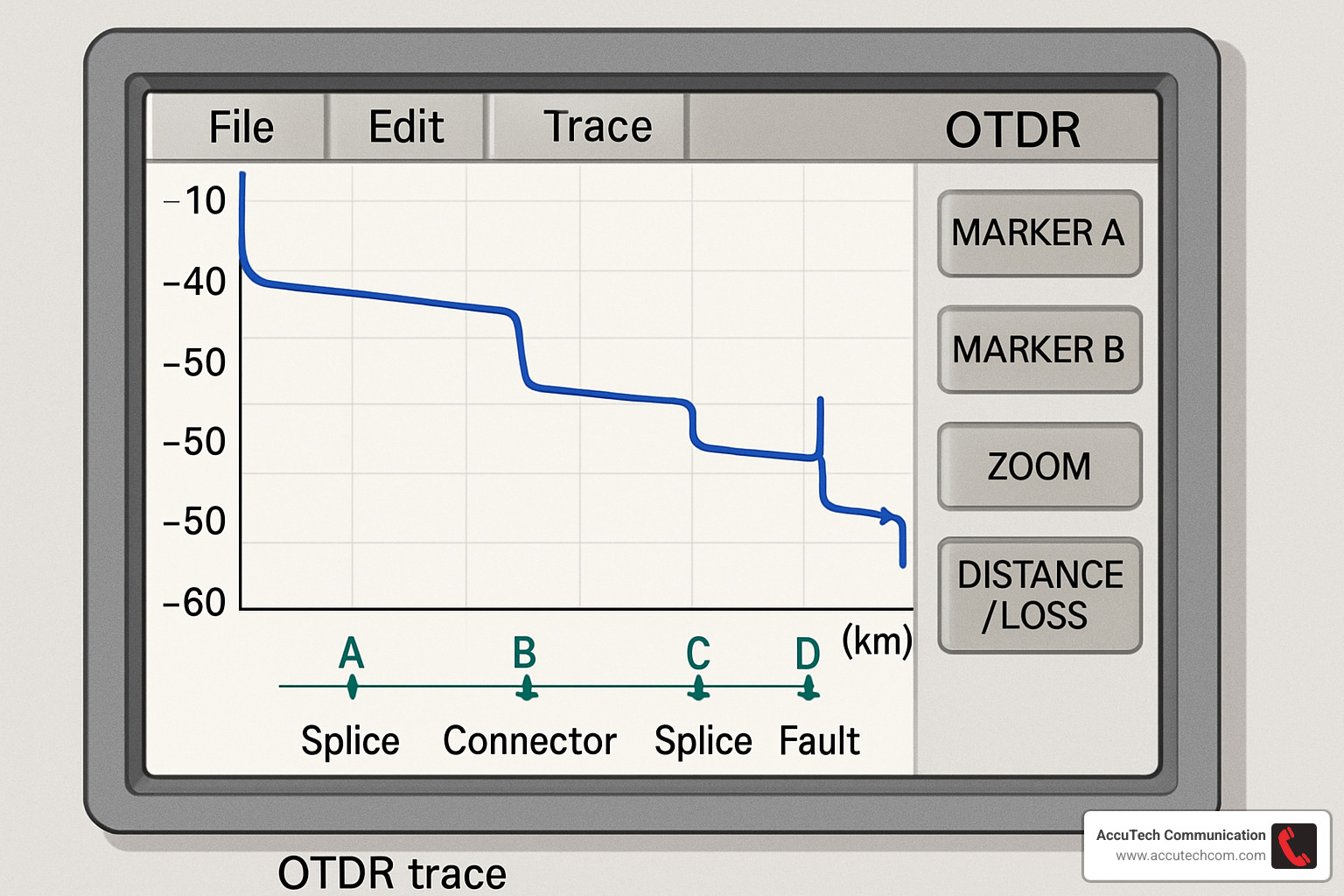

After everything’s connected, testing isn’t optional – it’s essential. Start with visual inspection using specialized microscopes to check connector end-faces. Even a tiny dust particle can cause major problems! Then measure actual light loss with a light source and power meter. For comprehensive analysis, an Optical Time Domain Reflectometer (OTDR) creates a detailed map of your fiber link, showing every splice, connector, and potential trouble spot.

Need professional splicing expertise? More info about Fiber Optic Splicing Contractors can connect you with certified specialists.

Ongoing Maintenance & Rapid Repairs

The best Fiber Optic Technology networks receive regular TLC. Preventive maintenance isn’t exciting, but it prevents those midnight emergency calls when systems fail.

Regular connector inspection should be part of your routine – those little end-faces collect dust like magnets! Proper cleaning using specialized fiber cleaning tools (never use shirt sleeves or alcohol wipes from your first-aid kit!) keeps signals flowing smoothly. I always recommend keeping detailed documentation of your fiber plant, including baseline OTDR traces. When trouble strikes, these references are worth their weight in gold.

For mission-critical networks, consider implementing monitoring systems that can detect subtle degradation before it becomes a full outage. These systems are like having a doctor continuously monitoring your network’s vital signs.

Despite our best efforts, damage happens – construction accidents, rodent damage (yes, they love fiber for some reason), or simply age-related issues. When problems occur, rapid repair becomes the priority:

First, locate the fault precisely using an OTDR – no use digging up 100 feet of pathway when the break is at the 53-foot mark. Then carefully access the damaged section, cut out the problem area, and fusion splice in a new section. Finally, comprehensive testing verifies the repair meets performance specifications.

Don’t have in-house fiber experts? Professional repair services can minimize your downtime. Learn More info about How to Repair Fiber Optic Cable for situations when quick recovery is essential.

Proper installation and maintenance aren’t just technical requirements – they’re investments in your network’s reliability and longevity. The care you put in today pays dividends for years to come.

Future Trends in Fiber Optic Technology

The world of Fiber Optic Technology isn’t standing still—it’s racing forward with innovations that will transform how we connect, communicate, and collect data. Let’s peek into the exciting future that’s unfolding right before our eyes.

Pushing Bandwidth Limits

Remember when a 56K modem seemed fast? Today’s fiber networks make that look like the digital Stone Age, and tomorrow’s will make today’s speeds seem quaint by comparison.

The hunger for bandwidth grows insatiably, with video streaming, cloud computing, and emerging technologies like VR all demanding more. Thankfully, fiber is rising to the challenge. The Ethernet roadmap shows us moving from today’s 400G connections to 800G and eventually to a mind-boggling 1.6T (1,600 gigabits per second). This progression follows what industry insiders call “Keck’s Law”—the optical equivalent of Moore’s Law—where fiber data rates double approximately every five years.

How are engineers achieving these feats? They’re getting creative with the light itself. Traditional systems operate in what’s called the C-band wavelength range (1530-1565 nm). By expanding to use the L-band (1565-1625 nm) and eventually the S-band (1460-1530 nm), we can dramatically increase capacity through existing fibers—like adding new lanes to a highway without widening the road.

Even more fascinating is Space Division Multiplexing (SDM), which uses multicore fibers—essentially several fiber cores bundled within a single strand—to multiply capacity. Combined with advanced coherent optics that encode more data in each light pulse, these technologies are pushing boundaries we once thought impossible.

The results? In 2023, researchers achieved a staggering 22.9 petabits per second over a single fiber. To put that in perspective, you could transmit the entire Netflix library in less than a second. The future is bright indeed—and moving at light speed.

Fiber Optic Lighting & Sensing Innovations

Fiber Optic Technology isn’t just about moving data—it’s illuminating our world and sensing changes in ways that were science fiction just decades ago.

Fiber optic lighting transports light from a central source to multiple locations through flexible fiber strands. Walk into a high-end restaurant with a twinkling star ceiling or visit a museum with subtle, heat-free illumination of sensitive artifacts, and you’re likely seeing fiber optics at work. These systems are particularly valuable in hazardous environments where electrical lighting might pose explosion risks, or in medical settings where precise, cool illumination is essential during procedures.

Perhaps even more is how Fiber Optic Technology is becoming our planetary nervous system through distributed sensing. A single fiber can now act as thousands of sensors along its entire length. Distributed Acoustic Sensing (DAS) can detect vibrations, making it perfect for monitoring pipelines for leaks, securing perimeters against intruders, or even observing seismic activity. Distributed Temperature Sensing (DTS) continuously measures temperature along the fiber—invaluable for fire detection in tunnels or monitoring industrial processes.

These sensing capabilities are changing industries from oil and gas to water management. Imagine a city where the same fiber network that delivers your internet also monitors water quality, detects leaks before they become sinkholes, and helps optimize the entire distribution system. That future isn’t just possible—it’s already beginning.

Greener, Smarter Infrastructure

As our world grapples with sustainability challenges, Fiber Optic Technology is evolving to be both greener and smarter.

Hollow-core fibers represent one of the most exciting developments in this space. By guiding light through air rather than glass, these fibers can reduce signal latency significantly—a game-changer for financial networks where microseconds translate to millions of dollars, or data centers seeking to minimize energy consumption while maximizing performance.

The physical infrastructure is getting greener too. New cable designs with easily separable components make end-of-life recycling more practical, reducing the environmental footprint of our digital world. When you consider the volume of cabling in modern cities, this seemingly small improvement could have substantial environmental benefits.

Fiber Optic Technology is also the backbone of smarter cities and infrastructure. Fiber-enabled IoT networks connect everything from traffic lights to air quality sensors, creating urban environments that respond intelligently to changing conditions. Imagine traffic signals that adjust based on actual traffic flow, or street lighting that dims when no one’s around—all coordinated through fiber networks.

Perhaps most fascinating is how artificial intelligence is being combined with fiber sensing to create predictive, self-healing networks. These systems can identify potential failures before they occur and automatically reroute traffic around problems, maintaining connectivity even when components fail.

Meanwhile, integrated photonics—essentially miniaturizing optical components onto silicon chips—promises to make network equipment smaller, more energy-efficient, and ultimately more sustainable.

These aren’t just technical improvements; they represent a fundamental shift toward communication infrastructure that’s more resilient, intelligent, and in harmony with our planet’s needs. At AccuTech Communications, we’re excited to help businesses across New England accept these innovations as they emerge.

Frequently Asked Questions about Fiber Optic Technology

Why is fiber faster than copper?

Ever wondered why fiber optic technology consistently outpaces traditional copper cabling? The answer lies in the fundamental physics of how these technologies work.

Light simply moves more efficiently than electricity through a medium. When data travels through fiber optic technology, it zooms along as light pulses, unbothered by the limitations that slow down electrical signals in copper cables.

The bandwidth potential of fiber is dramatically higher because light can be modulated at incredibly high frequencies. While copper struggles to push past 10 Gbps even over short distances, fiber comfortably supports 800 Gbps and beyond. The theoretical ceiling? We haven’t even reached it yet!

Another advantage is fiber’s remarkable signal integrity over distance. Copper signals weaken significantly as they travel, requiring frequent boosting. Fiber signals, however, maintain their strength over much longer spans, allowing for higher data rates without constant intervention.

Perhaps most importantly, fiber optic technology simply doesn’t suffer from electromagnetic interference. While copper cables act like antennas—picking up and creating electrical noise—fiber remains completely immune. This immunity means fiber performs flawlessly even in electrically noisy environments like manufacturing floors or alongside power lines.

How far can a signal travel before it needs amplification?

“How far can my fiber signal go?” is one of the most common questions we hear from clients considering fiber optic technology. The answer isn’t one-size-fits-all—it depends on several important factors.

First, the type of fiber makes an enormous difference. Single-mode fiber dramatically outperforms multimode when it comes to distance. While multimode fiber typically reaches its limit around 300-600 meters at gigabit speeds, standard single-mode fiber can travel 40-80 kilometers at 10 Gbps before needing a boost. Premium low-loss single-mode fiber pushes this boundary even further, sometimes exceeding 100 kilometers.

The wavelength of light also matters significantly. Some wavelengths experience less attenuation (signal loss) than others as they travel through glass. Network designers carefully select optimal wavelengths based on distance requirements.

Data rate plays a role too—higher speeds typically require more frequent amplification. A 100 Gbps signal generally can’t travel as far as a 10 Gbps signal without help.

For truly long-haul applications like submarine cables spanning oceans, repeaters are typically spaced 70-150 kilometers apart. The development of erbium-doped fiber amplifiers (EDFAs) revolutionized these long-distance connections by allowing direct amplification of optical signals without converting them to electricity first—a game-changer for global communications.

Can fiber optics be used for power as well as data?

Traditional fiber optic technology excels at moving data, not power. However, the industry has developed clever solutions to address the need for both power and data delivery.

The most practical approach today is composite cabling. These innovative cables house both optical fibers for data and copper conductors for power within a single jacket. Modern composite solutions can deliver up to 90 watts of electrical power over distances up to 1,500 feet while simultaneously providing virtually unlimited bandwidth through the fiber strands.

This neat solution has gained tremendous popularity for applications like security cameras, wireless access points, building automation systems, and industrial sensors. By running just one cable instead of two, businesses save on installation costs, reduce pathway congestion, and simplify their infrastructure.

For specialized situations where electrical isolation is critical, an emerging technology called Power over Fiber (PoF) offers an intriguing alternative. This approach uses high-power lasers to send optical power through fiber, which is then converted to electricity at the destination using photovoltaic cells. While still limited to delivering under 1 watt in most cases, PoF shines in unique environments like MRI rooms, hazardous locations, or high-voltage areas where complete electrical isolation matters more than power capacity.

At AccuTech Communications, we’ve helped numerous businesses across New England implement the right combination of power and data solutions for their specific needs, ensuring their networks remain both capable and future-ready.

Conclusion

Fiber optic technology has transformed our world in ways we couldn’t have imagined just a few decades ago. From those early experiments in the 1970s to today’s mind-boggling terabit systems, fiber has consistently delivered on its promise to connect us faster and more reliably than ever before.

Think about what we’ve covered in this journey through fiber optics:

We’ve explored how light dances through glass strands using total internal reflection, carrying our data with minimal loss over incredible distances. We’ve seen how different fiber types serve different needs—from the multimode cables connecting servers in a data center to the single-mode fibers stretching across ocean floors, linking continents.

But perhaps most fascinating is how fiber optic technology has expanded beyond telecommunications. Today, it’s saving lives in hospital operating rooms, monitoring the structural health of bridges, detecting pipeline leaks before they become disasters, and even creating stunning lighting displays that transform architectural spaces.

The innovation never stops. Engineers and scientists continue pushing boundaries, finding ways to squeeze more data through existing fibers, developing new materials that reduce signal loss, and creating intelligent networks that can heal themselves when problems arise.

For businesses across Massachusetts, New Hampshire, and Rhode Island, implementing the right fiber optic technology solution isn’t just about keeping up—it’s about gaining a genuine competitive advantage. A properly designed fiber network provides the reliability, scalability, and performance that modern businesses need to thrive in our data-driven world.

Whether you’re upgrading an existing network that’s struggling to keep pace with growing demands or building something new from the ground up, understanding these fundamentals helps you make smarter decisions that will serve your organization for years to come.

AccuTech Communications offers certified fiber solutions throughout New England, bringing expertise in design, installation, maintenance, and emergency repairs when you need them most. We’ve been helping organizations like yours steer the complexities of network infrastructure since 1993.

Ready to explore how fiber optic technology can transform your business connectivity? For a deeper dive into designing your network’s optical backbone, visit More info about Fiber Optic Cable.