How to install low voltage exterior lighting: Easy 2025

Why Low Voltage Exterior Lighting is Perfect for Your Property

How to install low voltage exterior lighting is simpler than most people think, and the results can transform your property’s appearance and safety. Here’s the quick overview:

Essential Steps:

- Plan your layout – Map fixture placement and calculate total wattage

- Install the transformer – Mount near GFCI outlet, connect main cable

- Run the cable – Dig 6-inch trenches, lay weather-resistant wire

- Connect fixtures – Use waterproof connectors to attach lights

- Test and adjust – Check all lights work, fine-tune angles at night

- Bury wires – Cover cables and restore landscaping

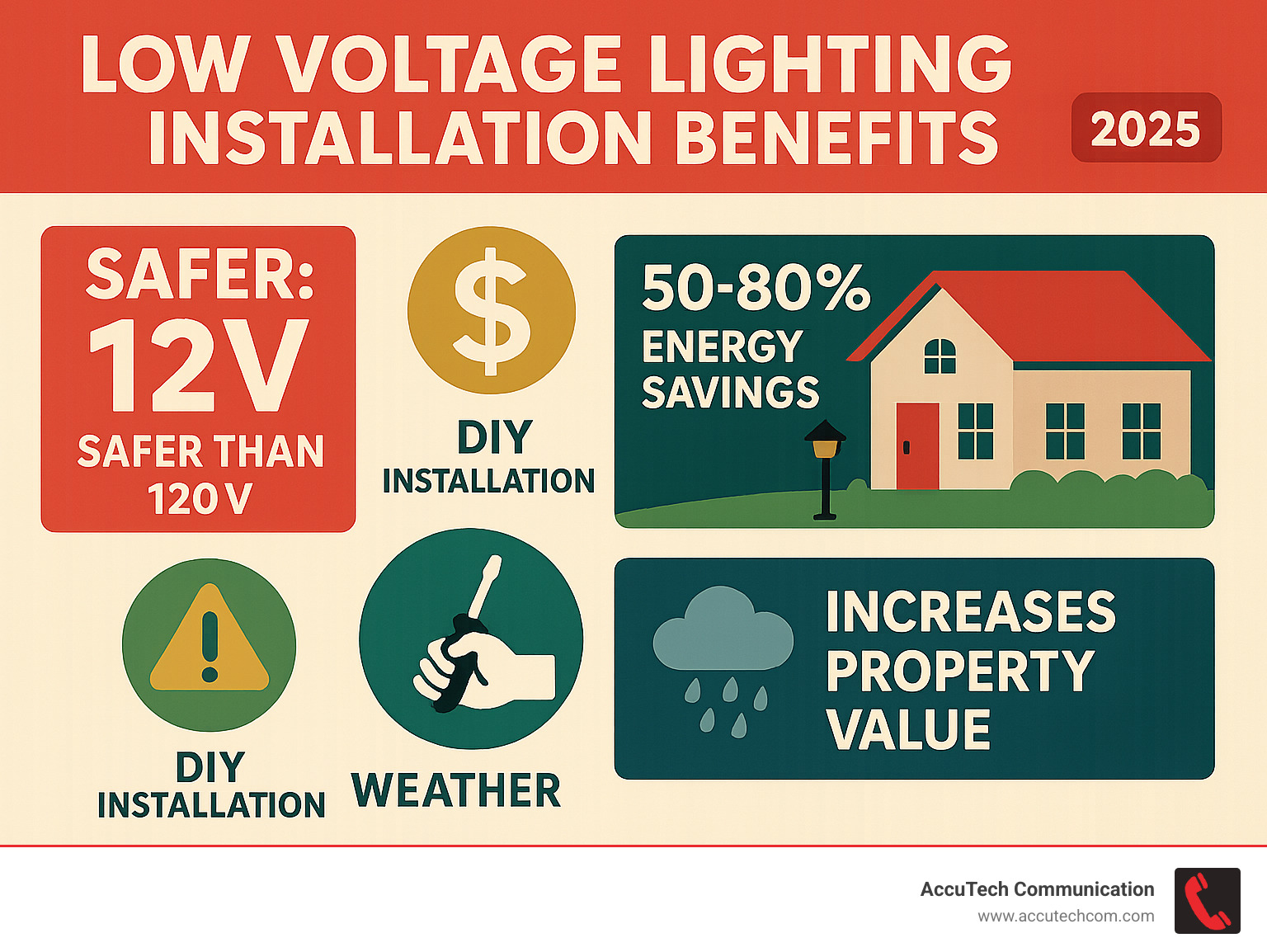

Low voltage lighting systems use a transformer to reduce your home’s standard 120-volt power down to just 12 volts. This makes installation much safer for DIY projects while still providing beautiful, professional-looking results.

The benefits are clear: improved curb appeal, improved safety for walkways and steps, and energy-efficient operation. An average system costs $450-600 and takes 8-10 hours to install, making it an accessible weekend project for most homeowners.

As someone who has spent decades working with low voltage systems in commercial settings, I’ve seen how proper installation techniques for how to install low voltage exterior lighting can make the difference between a system that lasts years versus one that fails within months. My experience at AccuTech Communications has taught me that attention to detail during installation pays dividends in long-term performance and reliability.

How to install low voltage exterior lighting word roundup:

Step 1: Planning Your Low-Voltage Lighting System

The secret to learning how to install low voltage exterior lighting successfully lies in thoughtful planning. Just like any worthwhile home improvement project, taking time upfront to map out your approach will save you headaches later. The good news? This is a manageable weekend project that most homeowners can tackle with confidence.

Your low-voltage lighting system revolves around three main system components: the transformer (which converts your home’s 120V power to safe 12V), weather-resistant low-voltage cable, and the light fixtures themselves. The project cost for materials typically ranges from moderate to reasonable for most properties, while the estimated time usually spans 8 to 10 hours of work – perfect for a Saturday-Sunday installation.

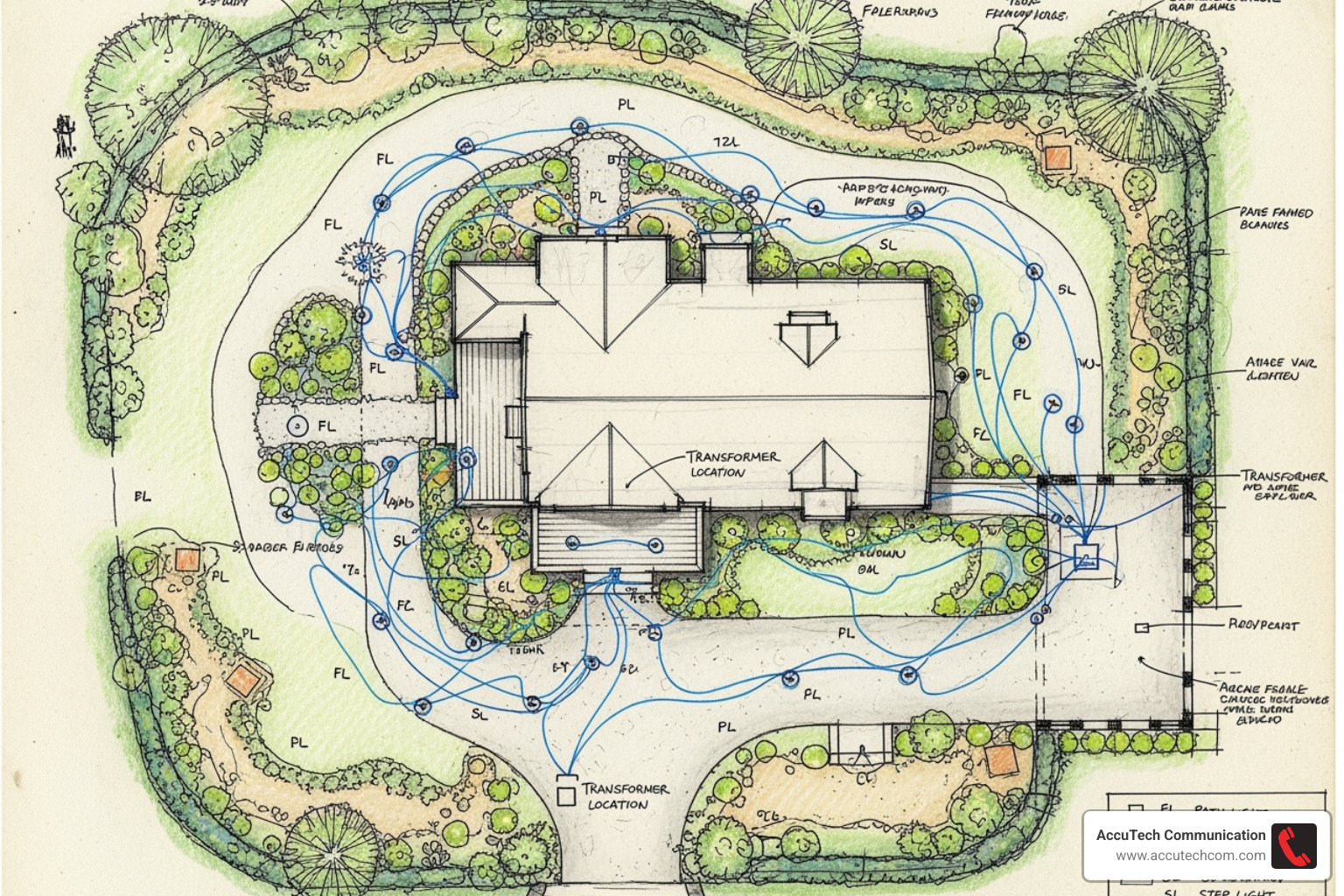

Designing Your Lighting Layout

Start by taking an evening stroll around your property with a notepad in hand. This nighttime walkthrough reveals exactly where you need illumination most. Mapping key features becomes much easier when you can see which areas disappear into darkness.

Sketching the plan on paper might feel old-school, but it’s invaluable. Mark your home’s outline, then identify what you want to showcase. That mature maple tree would look stunning with uplighting trees from below. Your home’s architectural features – maybe a beautiful stone entryway or interesting roofline – deserve highlighting too.

Don’t forget the practical side: highlighting walkways and steps dramatically improves safety for family and guests. For path light spacing, position fixtures 8-10 feet apart along walkways. This creates smooth, even lighting without harsh bright spots or dark gaps.

Here’s a pro tip from my years of low-voltage installations: place your first fixture distance from transformer at least 10+ feet away. This simple rule helps prevent voltage issues that can dim your lights or cause premature bulb failure.

Choosing the Right Components and Calculating Wattage

Your transformer serves as the system’s heart, safely converting household current to 12 volts. When selecting light fixtures, you’ll choose from spotlights for accenting features, path lights for walkways, and well lights that sit flush with ground level.

The LED vs Halogen debate is pretty much settled these days – LED fixtures win hands down. They use less energy, last longer, and handle voltage variations better than their halogen cousins.

Transformer sizing requires some simple math. Add up all your fixture wattages, then use this wattage calculation: take your total fixture watts and add 20% extra for future expansion. If your lights total 100 watts, choose a transformer rated for at least 120 watts.

Cable gauge selection matters more than many homeowners realize. The wire thickness affects how well power travels from transformer to fixtures:

| Wire Gauge | Best For |

|---|---|

| 14-gauge wire | Systems under 200 watts total |

| 12-gauge wire | Systems over 200 watts total |

For longer runs or main trunk lines, consider 10-gauge wire to minimize voltage drop. A smart approach uses heavier gauge wire for the main runs from your transformer, then lighter gauge for individual fixture connections.

Want to dive deeper into wire selection? Check out more info about different cable types for additional guidance.

Gathering Your Tools and Materials

Having the right tools transforms installation from frustrating to smooth sailing. You’ll need a flat-blade shovel or trenching tool for digging shallow cable trenches. Wire strippers prepare cable ends for clean connections.

Safety gear is non-negotiable: work gloves protect your hands during digging, and safety glasses shield your eyes from flying dirt or debris. Electrical tape adds extra security around connections, while a tape measure ensures accurate spacing.

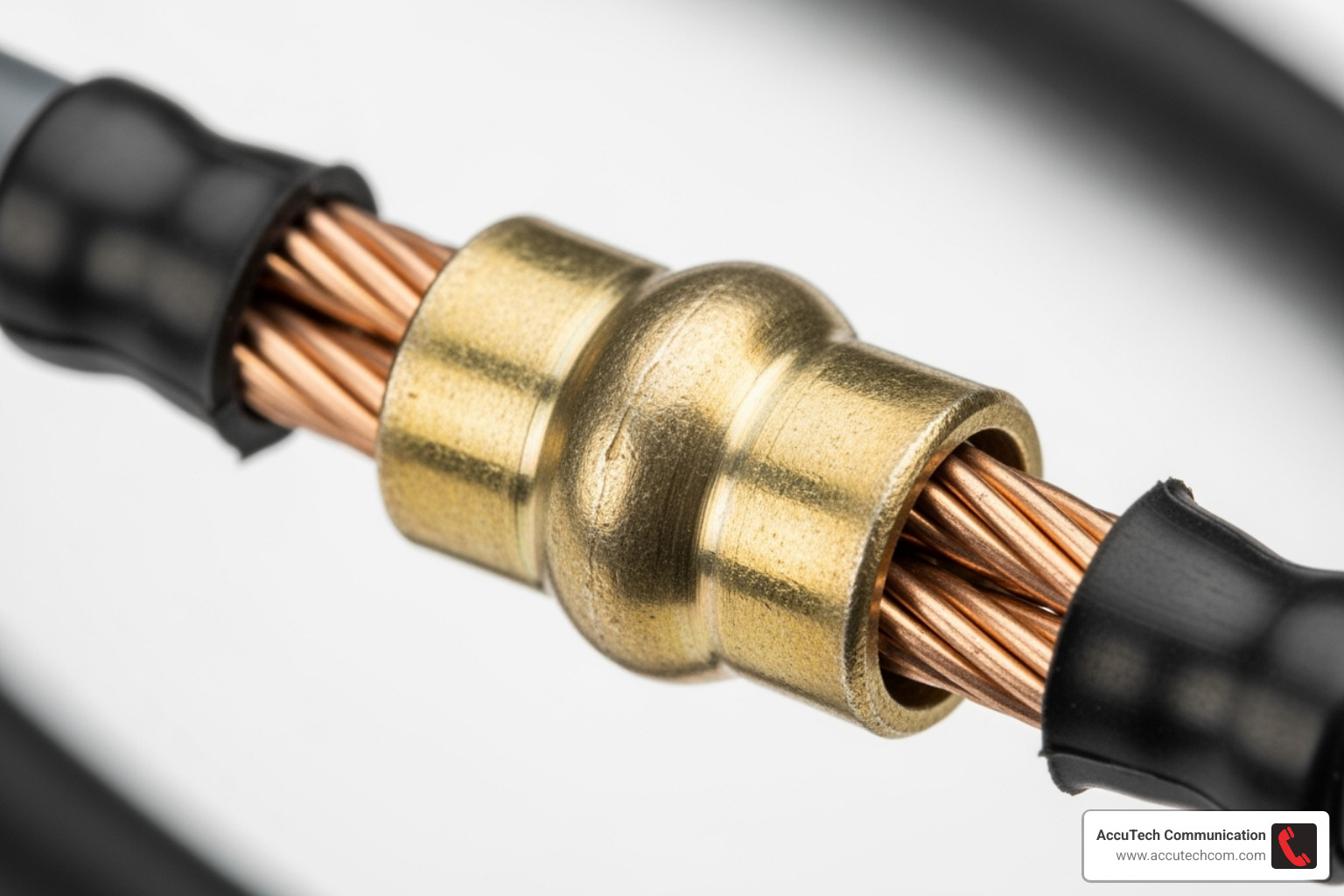

Here’s where experience matters: skip the cheap plastic waterproof wire connectors often included in starter kits. Instead, invest in quality brass barrel connectors with heat shrink tubing. They cost a bit more upfront but create truly waterproof seals that last for years.

A digital multimeter becomes your best friend for testing voltage at each fixture location. This simple tool helps ensure every light receives the proper 10.5 to 12 volts for optimal performance and longevity.

Step 2: How to Install Low Voltage Exterior Lighting – The Core Process

With your plan in hand and tools at the ready, it’s time to bring your outdoor lighting vision to life! Even though low-voltage systems are much safer than line-voltage, always exercise caution. We ensure our team at AccuTech Communications prioritizes safety on every project, and we encourage you to do the same.

How to Install and Connect the Transformer

Your transformer is the brain of your low-voltage system, converting high household voltage to safe low voltage. Choosing the right location is key: it should be central to your lighting layout, out of direct view if possible, and most importantly, near a GFCI (Ground Fault Circuit Interrupter) outdoor electrical outlet. This GFCI outlet is non-negotiable for safety, providing crucial protection against electrical shock.

Mount the transformer at least 12 inches above the ground level to protect it from moisture and debris. Use appropriate anchors for your home’s exterior surface (siding clips for vinyl, screws for masonry). Once mounted, plug it into your GFCI outlet. We highly recommend using a “while-in-use” weatherproof cover for the outlet to shield the transformer plug from the elements.

Connecting your main low-voltage cable to the transformer is straightforward. Strip about 1/2 inch of insulation from the ends of your main cable wires. Twist the strands slightly to keep them together, then insert them into the transformer’s low-voltage terminals, usually marked “common” and “12V” or “15V” (the higher voltage tap can help compensate for voltage drop on longer runs). Tighten the terminal screws securely.

For situations where the cable needs to pass through walls or other structures, learning how to install protective conduit is an important step to safeguard your wiring.

Running and Burying the Low-Voltage Cable

Before you put shovel to earth, there’s one critical step: Call 811! This free service ensures that all underground utility lines (gas, water, electric, communication) are marked, preventing dangerous and costly accidents. Never skip this step, even for shallow digging.

Once your utilities are marked, it’s time to lay out your cable. Follow your pre-planned design, running the cable from the transformer to each fixture location. We find it helpful to unroll the cable along your intended path above ground first, making it easier to adjust before burial.

Now, for the trenches. Low-voltage landscape lighting cable is typically buried at least 6 inches deep for protection. However, in garden beds, simply covering it with mulch or soil is often sufficient, as some sources suggest a shallow 3-inch depth is also acceptable for DIY. We prefer the slightly deeper 6-inch burial for improved protection. A clever technique for burying cable in lawns is the “sod-lifting” method: use a flat garden spade to push into the ground at a 45-degree angle, lift the sod to create a V-shaped trench, lay the cable, and then replace the sod. This minimizes disruption to your lawn.

Remember to leave some slack in the cable at each fixture location. This extra length (about 18 inches) will be invaluable for making connections and future adjustments. For added protection in high-traffic areas or under hardscaping, consider protecting the cable with Underground Electrical Conduit.

How to Connect the Individual Light Fixtures

With your main cable laid out, it’s time to connect the individual lights. First, assemble your light fixtures according to the manufacturer’s instructions, installing bulbs, lenses, and stakes as needed. Then, position them lightly in their planned spots.

Connecting the fixtures to the main power cable is a crucial step. Many low-voltage lighting kits come with simple quick-connectors that pierce the cable insulation. While these are easy, our experience shows they can be prone to failure over time due to moisture and corrosion. We strongly recommend cutting off these press-on connections and using high-quality, weatherproof brass barrel connectors with heat shrink tubing for all your connections.

To use these connectors, strip about 1/2 inch of insulation from the ends of both the main cable and the fixture wires. Insert the stripped wires into the connector, tighten the screws securely, and then apply heat shrink tubing over the connection to create a watertight seal. This might take a little more effort upfront, but it ensures a trouble-free and long-lasting installation.

Step 3: Testing, Adjusting, and Troubleshooting

You’re almost there! Before you bury all your hard work, test your system and make those crucial final adjustments. This step ensures everything is working perfectly and that your lights create the desired effect.

Testing the System and Making Final Adjustments

Once all your fixtures are connected, it’s time for the moment of truth. Turn on the transformer by plugging it into the GFCI outlet. Walk around your property and check each light. Do they all illuminate? Are they bright enough?

The most critical part of this phase is adjusting your fixture angles, and this is best done after dusk. The way light looks in daylight is very different from its nighttime effect. At night, you can clearly see the beam spread, highlight specific features, and most importantly, manage glare. Aim your lights to illuminate your desired features, not to shine directly into anyone’s eyes. You might need to make minor tweaks to the position or angle of a fixture, and that’s precisely why we left some slack in the cables! Fine-tuning light placement can dramatically impact the final aesthetic of your system.

Once you’re satisfied with the lighting effect, you can program your transformer’s timer or photocell settings for automatic operation.

Common Troubleshooting Tips

Even with careful planning, sometimes things don’t go exactly as expected. Here are a few common issues and how to troubleshoot them:

- Lights not working at all:

- Check the transformer: Is it plugged in? Is the GFCI outlet tripped? Reset the GFCI if needed.

- Check main connections: Ensure the main cable is securely connected to the transformer terminals.

- Check individual connections: Disconnect and reconnect any fixtures that aren’t lighting up. A loose or corroded connection is a common culprit.

- Check bulbs: A simple burned-out bulb can be the issue. Replace it.

- Lights are dim or inconsistent: This is a classic sign of voltage drop.

- What is voltage drop? It happens when the electrical current loses power over a long run of wire or if too many lights are on one line, causing lights further down the line to be dimmer.

- Use a multimeter: Test the voltage at the fixture. Halogen lights should receive between 10.5 to 12 volts for a consistent look and to avoid premature burnout. If the reading is too low, you have voltage drop.

- Solutions for voltage drop:

- Thicker cable: If your initial cable was too thin for the wattage/distance, upgrading to a lower gauge (thicker) wire can help.

- Limit wattage per line: A good rule of thumb is to put no more than 100 watts of lighting on one line. If you have, say, ten 20-watt lights (200 watts total) on one line, consider splitting it into two 5-light lines (100 watts each) by running a separate, shorter line from the transformer or creating a “tee” connection.

- Use the 15V tap: If your transformer has a 15-volt tap, try connecting the affected lines to it. The higher initial voltage can compensate for the drop.

Remember to promptly replace any burned-out bulbs. This prevents other bulbs in the system from being overworked and shortening their lifespan.

Step 4: Safety, Maintenance, and Final Touches

Congratulations! You’ve mastered the steps of how to install low voltage exterior lighting. Now, let’s talk about ensuring your system remains safe, beautiful, and functional for years to come.

Important Safety Considerations

While low-voltage systems are much safer for DIY installation than line voltage systems, safety should always be your top priority. Think of it as the foundation that everything else builds on.

GFCI protection is absolutely non-negotiable. Always plug your low-voltage transformer into a GFCI-protected outdoor outlet. This little device is your primary safeguard against electrical shock, and it could literally save your life. If you don’t have a GFCI outlet where you need it, have a qualified electrician install one before proceeding.

Call to 811 we mentioned? It bears repeating because hitting an underground utility line can be dangerous and expensive. Even though you’re only digging 6 inches deep, utility lines can sometimes be shallower than expected. This free service protects you, your neighbors, and essential services.

Proper cable burial isn’t just about aesthetics – it’s about safety too. That 6-inch depth protects your wiring from lawn aerators, garden tools, and curious pets. When you’re backfilling your trenches, take care not to damage the cable with rocks or sharp debris.

While low-voltage systems have fewer strict requirements than line-voltage installations, we always encourage following general safety standards. The National Electrical Code® provides comprehensive electrical safety guidelines that can help ensure your installation meets professional standards.

Maintaining Your System for Longevity

A little ongoing care makes all the difference between a system that looks great for years and one that starts failing after the first season.

Start by burying all exposed wires once you’ve finished testing and adjusting. This final step protects your cables from damage and keeps your landscape looking neat and professional. Take a final walk around your property to make sure no cables are left above ground.

Regular cleaning of your fixtures pays huge dividends in light output. Dirt, pollen, and mineral deposits can cut your light output in half without you even realizing it. A few minutes with a soft cloth and mild soapy water every few months keeps your lights shining bright. While you’re cleaning, check that the fixtures are still properly positioned and haven’t shifted.

Annual connection checks might sound tedious, but they prevent bigger problems down the road. Look for any loose connections, especially if you notice lights flickering or going dim. Those high-quality brass connectors we recommended will serve you well here – they’re much more resistant to corrosion than the plastic quick-connects.

When bulbs burn out, replace them promptly. A dead bulb can cause the remaining bulbs on that circuit to work harder, shortening their lifespan. It’s like one person calling in sick and everyone else having to pick up the slack.

Don’t forget about your landscape! Pruning plants that start blocking your light beams keeps your system working as designed. Plants grow, and what looked perfect at installation might need adjustment after a growing season or two. This is also a good time to check for any fixtures that might have been pushed out of position by growing roots or settling soil.

Your low-voltage lighting system should provide years of reliable service with just these simple maintenance steps. The time you invest in proper installation and care will reward you with beautiful, safe lighting that improves your property value and your family’s enjoyment of your outdoor spaces.

Conclusion

What a journey! You’ve successfully mastered how to install low voltage exterior lighting and transformed your property into something truly special. Take a moment to appreciate what you’ve accomplished – those beautifully illuminated walkways, the dramatic uplighting on your favorite tree, and that warm, welcoming glow that greets you every evening.

Your hard work has paid off in multiple ways. Your home’s curb appeal has gotten a major boost, creating that “wow factor” that makes neighbors stop and admire. More importantly, you’ve increased safety and security around your property by eliminating dark spots and clearly marking pathways, steps, and entrances.

This project proves that with careful planning and attention to detail, homeowners can tackle impressive installations themselves. The satisfaction of flipping that switch each night and seeing your vision come to life is incredibly rewarding.

That said, we know that not every lighting project fits the DIY mold. Complex wiring situations, larger commercial installations, or intricate business infrastructure require a different level of expertise and certification. When businesses in Massachusetts, New Hampshire, and Rhode Island need professional-grade solutions – whether it’s network cabling, business phone systems, or comprehensive data center technologies – that’s where AccuTech Communications shines.

Since 1993, we’ve built our reputation on delivering certified, reliable service with competitive pricing and an unwavering commitment to quality. We understand that your business infrastructure is the backbone of your operations, and it deserves expert hands.

Ready to bring professional expertise to your business’s low-voltage needs? Contact a professional low-voltage installer for your business needs and let us help you create the reliable, efficient systems your business deserves.