Why Low Voltage Cable Testing Protects Your Business Infrastructure

Low voltage cable testing is the process of verifying the integrity, safety, and performance of cables rated 600 volts or less through visual inspections and electrical measurements. Whether you’re commissioning a new installation or maintaining an existing system, proper testing prevents costly downtime, safety hazards, and performance issues in commercial environments.

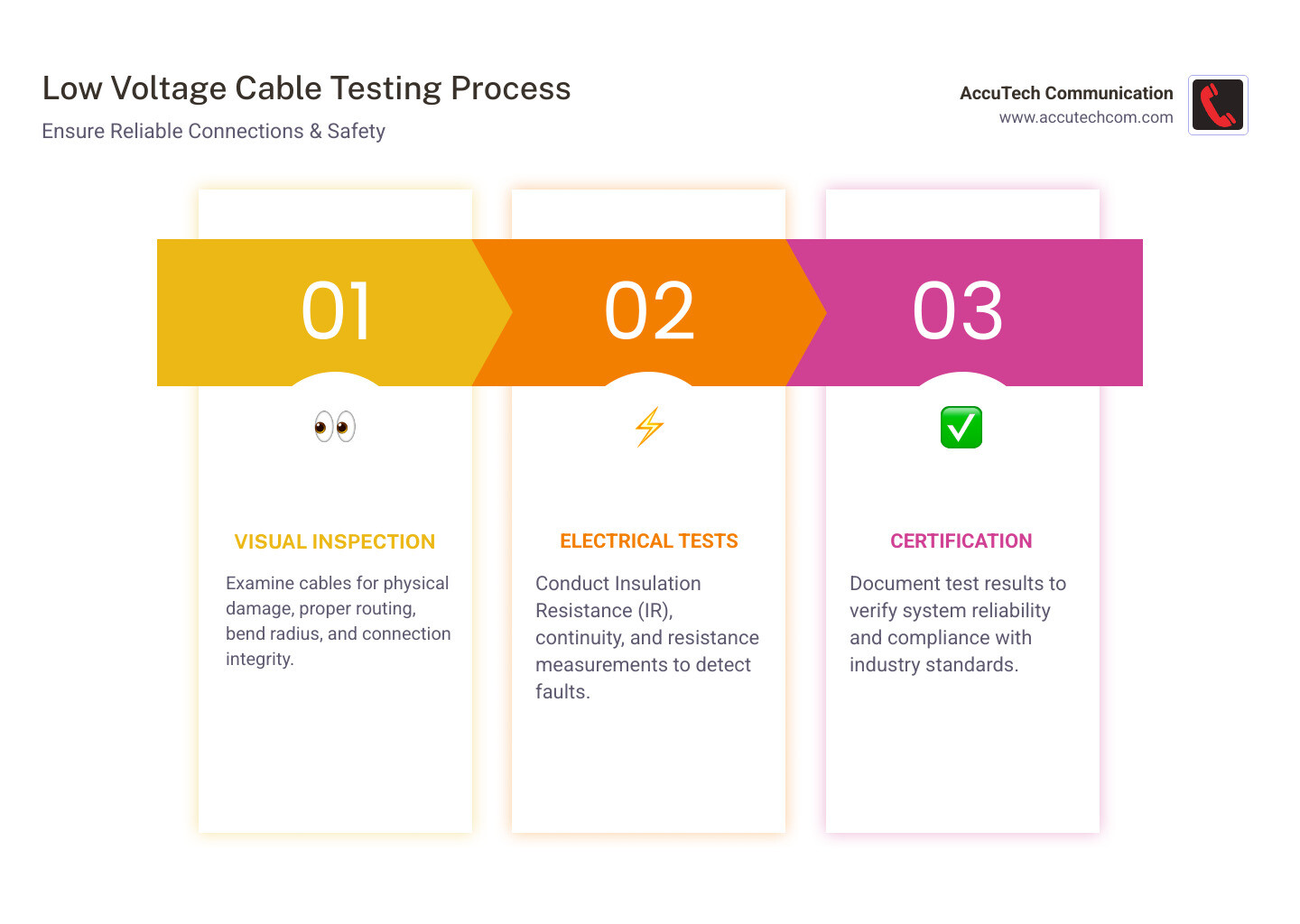

Essential Low Voltage Cable Testing Steps:

- Visual and Mechanical Inspection – Check for physical damage, verify cable routing, and inspect connections for proper termination

- Insulation Resistance Testing – Apply 500V DC for 300V-rated cable or 1000V DC for 600V-rated cable; minimum acceptable value is 50-100 megohms

- Continuity Testing – Verify correct phasing and end-to-end connections to prevent equipment malfunction

- Connection Resistance Verification – Use a low-resistance ohmmeter or calibrated torque wrench to ensure proper tightness

- Diagnostic Testing (Advanced) – Employ VLF or DAC methods for aging assessment and partial discharge detection

Cable systems are susceptible to degradation from heat, moisture, and physical stress. These conditions decrease electrical performance, leading to voltage drop, power loss, and increased resistance. In severe cases, neglected cables can create fire hazards or cause complete system failures.

Without proper testing, you risk:

- Unplanned downtime that disrupts business operations

- Safety concerns including short circuits and arcing

- Equipment damage from electrical faults

- Costly emergency repairs that far exceed preventive maintenance costs

I’m Corin Dolan, owner of AccuTech Communications, and since 1993 I’ve been helping businesses across Massachusetts, New Hampshire, and Rhode Island maintain reliable network infrastructure through comprehensive low voltage cable testing and structured cabling services. My team of certified technicians has the expertise and equipment to ensure your commercial communication systems meet industry standards and perform optimally.

Low voltage cable testing word roundup:

Why Low Voltage Cable Testing is Non-Negotiable

In the commercial landscapes of Massachusetts, New Hampshire, and Rhode Island, reliable infrastructure is the backbone of business. Low voltage cable testing is a non-negotiable practice that safeguards operations, prevents costly failures, and ensures the longevity of your investment. Though often unseen, these cables transmit vital data and power but degrade over time from heat, moisture, and physical stress. This degradation causes decreased performance, voltage drop, and increased resistance, which can escalate from minor issues to major failures. A degraded cable could cause intermittent connectivity in a Waltham data center or a power surge in a Worcester manufacturing plant, leading to inefficiency or serious safety hazards like fire. Proactive low voltage cable testing is paramount. If you need more information about the importance of a robust cabling infrastructure, you can find more info about structured cabling services.

The Primary Reasons for Testing

Performing low voltage cable testing and inspection is essential for several reasons:

- Commissioning New Installations: Verifies that new cables are installed correctly, meet design specifications, and are free from damage before the system goes live.

- Acceptance Testing: Confirms that newly installed cables conform to manufacturer and industry standards, ensuring reliable operation from day one.

- Maintenance Testing: Monitors the condition of existing cables over time to identify degradation and potential faults before they cause catastrophic failures.

- Troubleshooting Faults: Acts as a diagnostic tool to pinpoint the exact location and nature of a fault when a system has performance issues, speeding up repairs.

- Verifying System Reliability: Ensures the entire infrastructure remains reliable after modifications, repairs, or expansions.

- Safety Compliance: Helps confirm that the cabling system adheres to safety standards like NFPA 70E and poses no electrical hazards.

Consequences of Skipping Tests

Neglecting low voltage cable testing can lead to severe consequences that far outweigh the cost of proactive measures:

- System Failure: Complete failure of critical systems, such as data networks, security cameras, or manufacturing equipment.

- Data Loss: Cable faults can lead to data corruption or loss, impacting business continuity.

- Equipment Damage: Voltage fluctuations or short circuits from faulty cables can damage connected equipment, requiring expensive replacement.

- Safety Hazards: Degraded insulation or loose connections can create arc faults, electrical shocks, or fires, endangering employees and property in commercial environments in New Hampshire.

- Costly Repairs: Emergency repairs are significantly more expensive than scheduled maintenance due to overtime, expedited parts, and operational downtime.

- Unreliable Network Performance: Even without a complete failure, degradation leads to intermittent issues, slower speeds, and reduced efficiency, hurting productivity for businesses in Metro-west Boston.

Phase 1: Visual and Mechanical Inspections

A thorough visual and mechanical inspection is the foundational first step in any low voltage cable testing regimen. This crucial phase identifies obvious damage or installation errors that could compromise performance or safety. We examine every accessible part of your cabling infrastructure for red flags.

This includes checking for:

- Physical damage: Cuts, abrasions, crushing, or kinks on the cable jacket.

- Jacket and insulation integrity: Ensuring protective layers are intact and not brittle, cracked, or discolored.

- Proper routing and support: Verifying cables follow designated paths, avoid sharp bends (respecting bend radius), and are adequately supported to prevent strain.

- Environmental stress: Identifying signs of damage from heat, moisture, or UV exposure.

Inspecting Bolted and Compression-Applied Connections

Connections are common failure points. High resistance here can cause heat, power loss, and failure. We inspect both bolted and compression-applied connections.

For bolted connections, we check for:

- High resistance: Using a low-resistance ohmmeter, we check for resistance values that deviate by more than 50 percent of the lowest value.

- Loose connections: A calibrated torque wrench is used to verify bolts are tightened to manufacturer or industry specifications (e.g., ANSI/NETA Table 100.12).

- Overheating signs: Visual indicators like discoloration or pitting.

For compression-applied connections, we verify proper crimps, correct connector ratings for the cable size, and no exposed conductors.

Common connection-point failure signs include:

- Discoloration or charring

- Corrosion or oxidation

- Loose or missing hardware

- Melted or deformed components

- Visible arcing marks

- Inconsistent torque or improper crimps

Verifying Cable Data and Phasing

We also verify that installed cables match project documentation and that phasing is correct for system operation and safety. This involves:

- Comparing cable data to drawings: Checking cable sets, size, routing, and insulation ratings against blueprints.

- Verifying connection points and labeling: Ensuring cables connect to the correct terminals and are properly identified.

We also confirm correct phasing, especially in three-phase systems common in Massachusetts commercial buildings. Incorrect phasing can cause motors to run in reverse or create electrical faults. Our continuity tests, discussed next, provide a final verification of correct connection and phasing.

Phase 2: Crucial Electrical Tests for Low Voltage Cables

After visual inspections, we perform electrical tests by applying controlled signals to assess a cable’s internal condition, insulation integrity, and performance. These pre-energization checks detect hidden faults and ensure long-term reliability. For more detailed insights into network cable testing, you can refer to more info about network cable tester services.

Insulation Resistance Testing for low voltage cable testing

Insulation resistance testing with a megohmmeter is a fundamental part of low voltage cable testing. It measures the insulation’s effectiveness in preventing current leakage. Low resistance indicates deteriorated insulation, which can lead to shorts, ground faults, and safety risks. The test involves applying a DC voltage for one minute and measuring the resistance.

- Test Voltages: We follow industry standards, applying 500V DC for 300V-rated cable and 1000V DC for 600V-rated cable, unless manufacturer data specifies otherwise.

- Minimum Acceptable Values: While manufacturer data is best, NETA guidelines are a reliable benchmark. For acceptance tests, values should be no less than 100 megohms. For maintenance, values should be no less than 50 megohms, as referenced in standards like the ANSI/NETA Standard for Acceptance Testing Specifications.

Continuity and Resistance Measurement

These tests confirm the conductor path’s integrity and proper connections.

- Continuity Tests: We perform end-to-end verification to ensure correct cable connection and phasing, preventing equipment malfunction or electrical faults.

- Verifying Uniform Resistance: For parallel conductors, we use a low-resistance ohmmeter to ensure they share the load uniformly. A resistance value that deviates by more than 50 percent of the lowest value indicates a problem like a loose connection or broken strand, which can cause overheating and failure.

Advanced Diagnostics: VLF and Damped AC (DAC) Testing

For deeper insights into cable health, especially for aging infrastructure, advanced diagnostics like Very Low Frequency (VLF) and Damped AC (DAC) testing are used. While traditional DC voltage testing can be detrimental to modern cables, these AC-based methods provide a safer, more informative assessment.

- VLF (Very Low Frequency) Testing: This method uses an AC voltage at a very low frequency (e.g., 0.1 Hz) to test long cables with portable equipment. As outlined in the IEEE Guide for Field Testing of Shielded Power Cable Systems Using VLF, VLF can be used for withstand tests (pass/fail) and diagnostic measurements like tan delta (to assess insulation aging) and partial discharge (to find localized defects).

- Damped AC (DAC) Testing: DAC testing applies a brief, decaying AC impulse. This time-limited stress is ideal for testing aged cables, as it can detect partial discharge defects that pose a long-term risk without causing a full breakdown during the test.

Each method has its place. VLF and DAC provide diagnostic data that helps prioritize maintenance, while simple withstand tests offer a pass/fail result.

Adhering to Standards and Using the Right Tools

In the field of low voltage cable testing, adherence to industry standards and the use of precise, calibrated equipment are non-negotiable. These elements combine to ensure the accuracy, reliability, and comparability of our test results, allowing us to deliver consistent, high-quality service to our commercial clients across Massachusetts, New Hampshire, and Rhode Island. Without them, we’d be working in the dark, unable to guarantee the safety or performance of your critical infrastructure.

Key Standards and References for low voltage cable testing

Our practices are guided by reputable organizations and their comprehensive standards:

- NETA (InterNational Electrical Testing Association): NETA provides widely recognized standards for acceptance testing (NETA ATS) and maintenance testing (NETA MTS) of electrical power equipment and systems. These documents outline specific test procedures, acceptance criteria, and recommended test values for various components, including low voltage cables.

- IEEE (Institute of Electrical and Electronics Engineers): The IEEE 400 series of standards are particularly relevant for cable testing. For instance, IEEE 400.1 (for HVDC testing) and IEEE 400.2 (for VLF testing) provide detailed guides for field testing of shielded power cable systems. While often focused on higher voltages, the principles and methodologies can be adapted or inform practices for low voltage cable testing where applicable.

- IEC (International Electrotechnical Commission): IEC standards define international specifications for electrical, electronic, and related technologies. Various IEC standards cover cable construction, testing methods, and safety, such as IEC 60229 for sheath testing.

- NFPA 70E (National Fire Protection Association): This standard focuses on electrical safety in the workplace. While not directly a testing standard, it dictates the safety protocols that must be followed when performing any electrical work, including low voltage cable testing, to protect personnel from electrical hazards.

- Manufacturer’s Published Data: Always the primary reference. Cable manufacturers provide specific test parameters, acceptable values, and installation guidelines for their products. We prioritize this data to ensure tests are performed precisely as intended for the specific cable type.

The Technician’s Toolkit: Essential Testing Equipment

A skilled technician is only as effective as their tools. For low voltage cable testing, a specialized toolkit is indispensable:

- Low-Resistance Ohmmeter (DLRO or Micro-Ohmmeter): Used to measure very small resistances, typically in micro-ohms. This is critical for assessing the quality of bolted and compression connections, and for verifying uniform resistance in parallel conductors.

- Insulation Resistance Tester (Megohmmeter): As discussed, this device applies a high DC voltage and measures the resistance of the cable’s insulation. Essential for checking for insulation degradation or damage.

- Calibrated Torque Wrench: For bolted connections, ensuring that bolts are tightened to the correct specification prevents both loose connections (high resistance) and over-tightening (damage to conductors or insulation). Calibration ensures accuracy.

- Thermographic Camera (Infrared Camera): A powerful diagnostic tool that detects heat signatures. When a system is under load, connections with high resistance will generate excess heat, appearing as “hot spots” on the thermal image. This allows for non-contact, non-intrusive identification of potential problem areas.

- VLF Test Set: For advanced diagnostic testing, a VLF test set generates very low frequency AC voltages (sine or cosine-rectangular) for withstand and diagnostic tests like tan delta and partial discharge measurements.

- Time Domain Reflectometer (TDR): While not exclusively for electrical testing, a TDR is invaluable for fault location. It sends a signal down the cable and measures reflections to pinpoint breaks, shorts, or impedance changes, helping to locate faults quickly and accurately.

Frequently Asked Questions about Low Voltage Cable Testing

Here are answers to common questions our commercial clients in Marlborough, MA, and beyond have about low voltage cable testing.

What are the minimum acceptable insulation resistance values for low voltage cables?

The best source is always the cable manufacturer’s published data. If that’s unavailable, we follow NETA industry guidelines for low voltage cable testing:

- Acceptance Testing (New Cables): Values should be no less than 100 megohms.

- Maintenance Testing (Existing Cables): Values should not be less than 50 megohms.

These are general benchmarks; the actual acceptable value depends on the cable’s voltage rating, length, and environment. Our technicians interpret these readings in context.

How often should low voltage cables be tested?

The frequency of low voltage cable testing depends on several factors:

- Acceptance Testing: This is mandatory for all new installations before they are energized.

- Maintenance Testing: The schedule for existing cables is determined by:

- Criticality: Critical systems (data centers, emergency power) require more frequent testing.

- Environment: Harsh conditions (heat, moisture, chemicals) accelerate degradation and require more frequent checks.

- Age and History: Older cables or those with a history of borderline results should be tested more often.

- Industry Standards: NETA’s Maintenance Testing Specifications (MTS) provides recommended frequencies.

- Operational Needs: Facilities in Rhode Island with continuous operations may test more frequently to minimize downtime.

A typical maintenance schedule might be every 1 to 5 years, but this varies based on the factors above.

What’s the difference between a withstand test and a diagnostic test?

These two tests serve different purposes in low voltage cable testing:

-

Withstand Test (Go/No-Go):

- Purpose: A pass/fail test to verify insulation integrity.

- Method: Applies a higher-than-normal voltage for a set time. If the cable holds the voltage, it passes. A failure indicates a severe defect.

- Outcome: Confirms a cable is safe for service but doesn’t assess its overall long-term health or rate of degradation.

-

Diagnostic Test:

- Purpose: To assess the overall condition and quality of the insulation to predict future performance without causing a breakdown.

- Method: Measures electrical properties like Tan Delta (dielectric loss) or Partial Discharge (PD) to detect aging and defects.

- Outcome: Provides data on the insulation’s condition, allowing for condition-based maintenance (repairing/replacing cables based on their actual state, not just age).

A withstand test is a pass/fail exam, while a diagnostic test is a detailed health report. Both are crucial for ensuring long-term reliability.

Conclusion: Ensuring Network Reliability Through Professional Testing

The integrity of your low voltage cable testing infrastructure is directly tied to the efficiency, safety, and profitability of your commercial operations in Massachusetts, New Hampshire, and Rhode Island. From the initial installation to ongoing maintenance, a comprehensive approach to low voltage cable testing is not just a best practice—it’s an absolute necessity.

We’ve explored the critical phases of this process, starting with meticulous visual and mechanical inspections to catch physical damage and ensure proper connections. We then digd into essential electrical tests, including insulation resistance for gauging insulation health, continuity and resistance measurements for verifying connections and balanced loads, and advanced diagnostics like VLF and DAC testing for deeper insights into cable degradation. Adherence to industry standards from NETA, IEEE, and IEC, coupled with the use of specialized, calibrated equipment, underpins every step we take.

Neglecting these crucial steps can lead to severe consequences: unplanned downtime, costly emergency repairs, equipment damage, and, most importantly, safety hazards. Proactive low voltage cable testing is your best defense, translating into improved safety, optimized performance, and extended asset life for your critical systems.

At AccuTech Communications, we understand that your business relies on seamless connectivity and robust power distribution. Our certified technicians bring decades of experience and a commitment to quality to every project, ensuring your low voltage cabling is tested, verified, and ready to perform. Trust us to safeguard your infrastructure with professional, reliable low voltage cable testing services. To learn more about how we can support your business, please visit more info about network cabling installation.