Network Cable Metal Conduit: Ultimate Guide 2025

Understanding Network Cable Metal Conduit

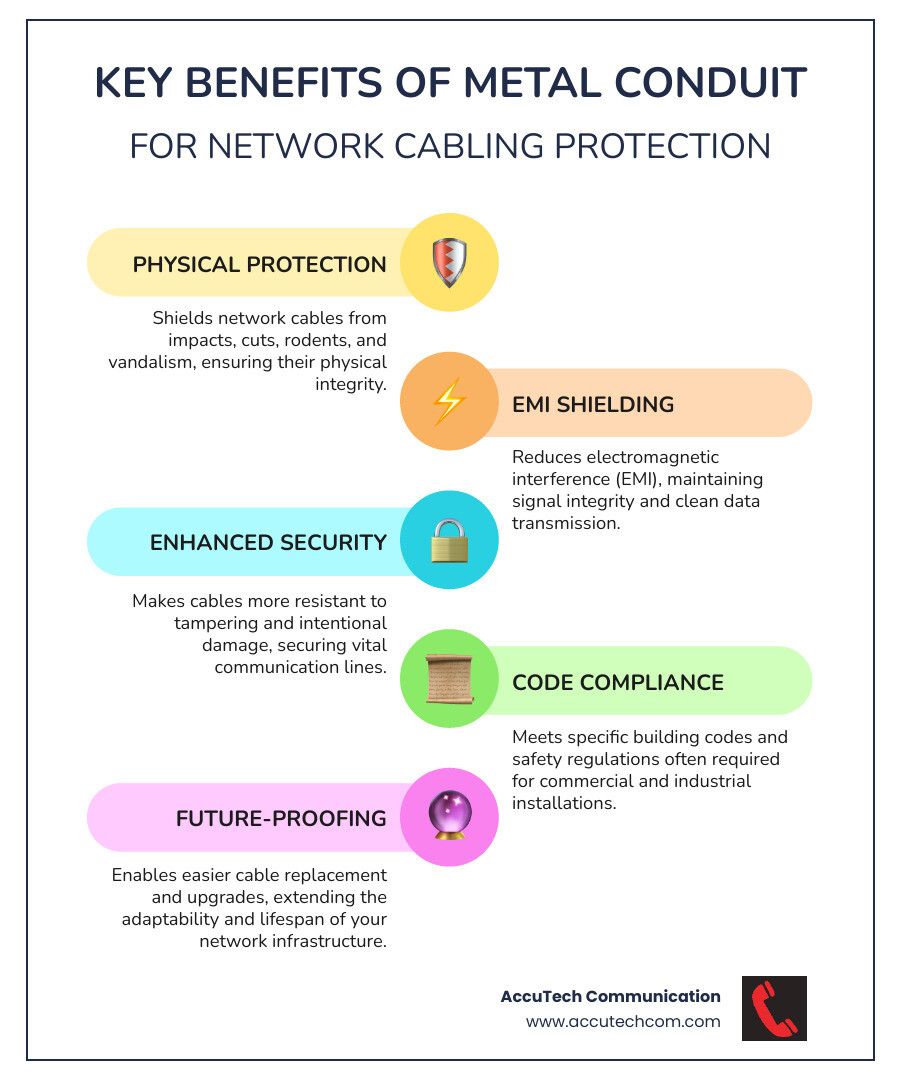

To protect crucial network cables, network cable metal conduit is a top choice. This durable pathway keeps cables safe and ensures your network runs smoothly. Metal conduit is often chosen for its key benefits:

- Physical Protection: Shields cables from impacts, cuts, and rodents.

- EMI Shielding: Reduces electromagnetic interference for clean data signals.

- Security: Prevents tampering and intentional damage.

- Code Compliance: Required by many building and safety regulations.

- Future-Proofing: Simplifies future cable upgrades without wall demolition.

Your business’s data and communication lines need strong protection, and metal conduit offers that robust defense. This guide covers everything you need to know about using metal conduit for your network cables.

As Corin Dolan, owner of AccuTech Communications, I’ve spent decades building reliable network infrastructures, including extensive work with network cable metal conduit. My experience ensures robust and secure data pathways for businesses across Massachusetts, New Hampshire, and Rhode Island.

Why Use Metal Conduit for Your Network Cabling?

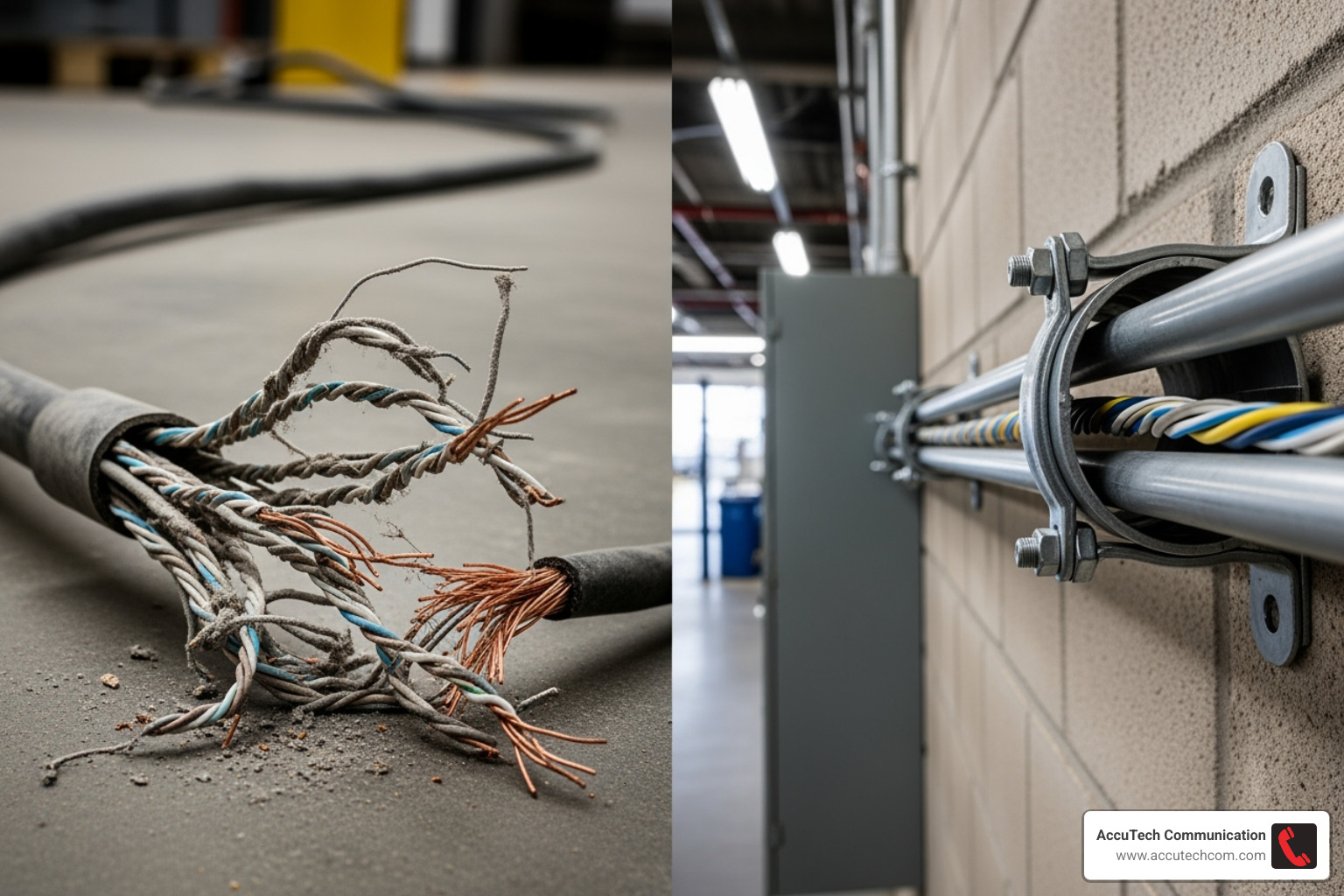

When protecting your network infrastructure, network cable metal conduit provides a fortress for your business’s lifelines.

Physical Protection

Your network cables carry vital data and deserve serious protection. Metal conduit acts as armor, providing essential impact resistance against accidental bumps from equipment or construction. It also offers crucial rodent protection, as critters cannot chew through metal. For exposed cables, such as those for outdoor security cameras, conduit provides vandal-proofing, making it difficult for anyone to intentionally cut or damage your network.

Improved Security

Beyond physical protection, metal conduit adds a significant security layer. Enclosing cables makes them much harder to access, preventing data tapping or intentional service disruption. For businesses handling sensitive information, this physical barrier is invaluable.

Future-Proofing

Network cable metal conduit is a smart investment for the future. With conduit in place, cable replacement and upgrades are far simpler. New cables can be pulled through existing pathways without tearing into walls or ceilings, saving significant time, money, and disruption. This long-term adaptability creates a permanent pathway that can handle evolving technology, paying dividends for years.

For more detailed information on how we design and implement robust cabling infrastructures, check out our page on Cable Infrastructure.

Superior EMI Shielding and Performance

Electromagnetic interference (EMI) from sources like lights, motors, and power lines can disrupt your network. Network cable metal conduit acts as a shield against this electrical noise. The metal enclosure creates a Faraday cage effect, blocking external interference from reaching your cables. When properly grounded as required by the National Electrical Code, the system becomes even more effective at eliminating noise.

While modern Unshielded Twisted Pair (UTP) cables have built-in protection, combining them with metal conduit offers robust defense. For high-EMI environments like manufacturing plants, using Shielded Twisted Pair (STP) cables inside conduit provides maximum protection. The minor attenuation increase (around 2-3%) is a small trade-off for the immense protective benefits.

If you’re curious about the technical details of EMI protection, this discussion provides some interesting insights: Is an ethernet cable threaded inside a metal conduit is more protected from elec…

When to Choose Metal Over PVC or Other Solutions

Choosing the right conduit depends on your environment, budget, and code requirements. While network cable metal conduit is often the best choice, other solutions like PVC or cable trays have their place.

| Comparison Criteria | Metal Conduit | PVC Conduit | Cable Trays |

|---|---|---|---|

| Physical Strength | Excellent – handles heavy impacts | Good – can crack under heavy impact | Variable – depends on design |

| Fire Safety | Excellent – contains and stops fire spread | Good – flame retardant but will melt | Variable – open design limits containment |

| EMI Protection | Excellent – acts as Faraday cage | None – no shielding properties | None – completely open |

| Cost | Higher – materials and installation | Lower – easier to work with | Moderate – depends on complexity |

| Installation Ease | More complex – requires special tools | Easier – cut, glue, and bend | Moderate – assembly required |

Metal conduit excels in industrial environments due to its strength and fire resistance. It’s also often required in commercial buildings, especially in plenum spaces, for fire safety. For corrosive environments, galvanized steel is effective, but PVC-coated metal or PVC conduit might be necessary depending on the specific chemicals involved.

Types of Metal Conduit for Network Cabling

Choosing the right type of network cable metal conduit depends on the specific needs of your environment. Each variety, typically made from steel or aluminum, offers unique strengths and is designed for different situations.

Rigid Metal Conduit (RMC)

RMC has the thickest walls of any metal conduit, offering maximum physical protection. Made from galvanized steel or aluminum, it uses threaded connections for a rigid and secure pathway. RMC is the top choice for industrial facilities, outdoor installations, and hazardous locations where the highest level of durability is required.

For a deeper dive into steel conduits, including RMC, you might find this resource helpful: The Basics of Steel Conduit.

Intermediate Metal Conduit (IMC)

IMC offers a great balance of strength and lighter weight compared to RMC. It’s typically made from rigid steel and provides excellent physical protection. Like RMC, it uses threaded connections, ensuring a durable system. IMC is a popular and cost-effective choice for many commercial and industrial applications in Massachusetts, New Hampshire, and Rhode Island.

To explore more about conduit options for both electrical and network wiring, check out our insights on Conduit for Electrical Wire.

Electrical Metallic Tubing (EMT)

Often called “thin-wall” conduit, EMT is lightweight and easier to handle and install. It uses unthreaded, setscrew or compression-type fittings, which simplifies assembly. Its thin walls make it easy to bend on-site for custom routes. EMT is primarily used for exposed indoor wiring in commercial and light industrial buildings.

If you’re curious about how EMT can improve your network connectivity, we encourage you to explore our page on Enhancing Connectivity: Exploring EMT Piping Service by Accutech Communication.

Flexible Metal Conduit (FMC) and Liquid-Tight (LFMC)

Flexible Metal Conduit (FMC) is a helically wound tube that can be bent by hand, making it ideal for tight spaces or connecting to vibrating equipment. Liquid-Tight Flexible Metal Conduit (LFMC) adds a waterproof plastic coating, making it suitable for damp or outdoor locations.

Installation Warning: Flexible conduit is not recommended for long runs where cables are pulled. Its tendency to shift can damage cable jackets, especially on delicate network cables. Use it sparingly for short, specific connections where its unique flexibility is essential. For most backbone runs, rigid or intermediate metal conduits are far superior.

Best Practices for Installing Network Cable Metal Conduit

Proper installation is as critical as choosing the right network cable metal conduit. A poorly installed system can cause performance issues and cable damage. At AccuTech Communications, we prioritize precision and follow these best practices:

- Route Planning: We carefully map the conduit path, considering obstructions and future access for maintenance or upgrades.

- Minimizing Bends: Each bend adds friction. We limit runs to two 90-degree bends between pull points and use wide, gradual “sweeps” to protect cables.

- Proper Pulling: We use fish tape and high-quality, wax-based cable lubricant to ensure cables glide smoothly, reducing friction and preventing damage.

- Preventing Cable Damage: We de-burr all cut conduit ends and install plastic bushings to protect cable jackets from sharp edges. We also carefully manage pulling tension, never exceeding the cable’s limit (typically 25 lbs for Ethernet).

For more in-depth guidance on how we approach conduit installations, please visit our page on How to Install Electrical Conduit.

Calculating Conduit Fill Ratio for network cable metal conduit

Correctly calculating how much space cables take up inside a network cable metal conduit is critical for performance and future growth. The National Electrical Code (NEC) sets clear limits:

- Initial Installations: Never exceed 40% capacity. This minimizes friction, prevents cable damage during pulling, and leaves room for future additions.

- Subsequent Additions: The fill should not exceed 60% capacity.

Following these fill ratios is key to future-proofing your network. It also prevents heat buildup, especially with Power over Ethernet (PoE) cables, and makes pulling cables much safer and easier. Overfilling conduit can degrade performance and damage cables.

Here’s a general guide for how many Cat6 plenum-rated cables might fit in common EMT conduit sizes at the 40% fill ratio. Always check your specific cable’s specs for precise calculations:

- 3/4 inch EMT Conduit: Approx. 6 Cat6 cables.

- 1 inch EMT Conduit: Approx. 8 Cat6 cables.

- 1.25 inch EMT Conduit: Approx. 15 Cat6 cables.

- 1.50 inch EMT Conduit: Approx. 20 Cat6 cables.

- 2.00 inch EMT Conduit: Approx. 35 Cat6 cables.

Special Considerations for Power over Ethernet (PoE)

Power over Ethernet (PoE) sends power and data over one cable, but this generates heat. When PoE cables are bundled in a network cable metal conduit, this trapped heat can degrade performance and shorten cable life. For this reason, cable bundling limits for PoE are often stricter than for data-only cables. It’s crucial to consult manufacturer guidelines, especially for high-power PoE (PoE+/PoE++). Using larger conduit or reducing the number of cables per run may be necessary. We select the appropriate cable category to ensure proper heat dissipation and reliability.

Safety and Code Compliance for network cable metal conduit

When installing network cable metal conduit, safety and code compliance are non-negotiable.

- Grounding and Bonding: The entire metal conduit system must be properly grounded to the building’s main ground. This provides a safe path for fault currents and improves EMI shielding.

- Fire Safety: Metal conduit is non-combustible and helps contain fire. In plenum spaces (areas for air circulation), plenum-rated cables (CMP) are required. Any penetrations through fire-rated walls must be sealed with firestopping materials.

- Separation from Power Cables: The National Electrical Code (NEC) strictly prohibits running network cables in the same conduit as electrical power wiring. This prevents severe shock and fire hazards and avoids EMI that can corrupt data signals. Always use separate conduits.

For comprehensive guidelines, always consult the NEC guidelines and local building codes. Our certified technicians are familiar with these regulations, ensuring every installation is safe and compliant.

Frequently Asked Questions about Network Cable in Metal Conduit

Here are answers to common questions about using network cable metal conduit to help you make informed decisions for your infrastructure.

Can I run network and power cables in the same metal conduit?

Absolutely not. The National Electrical Code (NEC) strictly prohibits running low-voltage network cables in the same conduit as high-voltage power wiring. This practice creates serious safety hazards, including risk of electrical shock and fire. Furthermore, the electromagnetic interference (EMI) from power lines causes crosstalk issues, which can slow your network, cause data errors, and lead to unreliable performance. Always use separate conduit pathways for network and electrical cabling.

Do I need shielded (STP) cable if I’m using metal conduit?

This depends on your environment. A properly grounded network cable metal conduit provides excellent EMI shielding. For most office environments, this protection is sufficient for standard unshielded twisted pair (UTP) cables. However, in environments with very high EMI—such as industrial plants with large motors or heavy electrical equipment—using shielded twisted pair (STP) cable inside the conduit provides the maximum level of protection. This dual-layer approach ensures data integrity in the most challenging conditions.

How far can I pull network cable through a metal conduit?

To prevent cable damage, we follow strict guidelines. A single pull should not exceed 100 feet. We also limit runs to a maximum of two 90-degree bends between pull points. For longer or more complex runs, we install intermediate pull points (junction boxes) to pull cables in shorter, safer segments. It’s also critical to stay below the cable’s maximum pulling tension, which is typically 25 pounds-force (lbs) for Ethernet cables. Exceeding this can stretch the wires and ruin the cable.

Conclusion

Choosing network cable metal conduit is a strategic investment in a robust and reliable network foundation. It provides superior physical protection, excellent EMI shielding, improved security, and makes your infrastructure future-proof.

However, the benefits of metal conduit are only realized through proper installation. This includes careful planning, correct fill ratios, and adherence to all safety and code requirements, especially the critical separation of network and power cables.

At AccuTech Communications, our certified expertise ensures your conduit installation is not just compliant, but optimized for performance and longevity. We build secure data pathways for businesses across Massachusetts, New Hampshire, and Rhode Island.

To ensure your network’s foundation is ready for anything, trust the professionals. Contact us for your Structured Cabling needs today to build a network that truly supports your success.