Underground Electrical Conduit: Top 5 Tips for 2024 Durability

Introduction

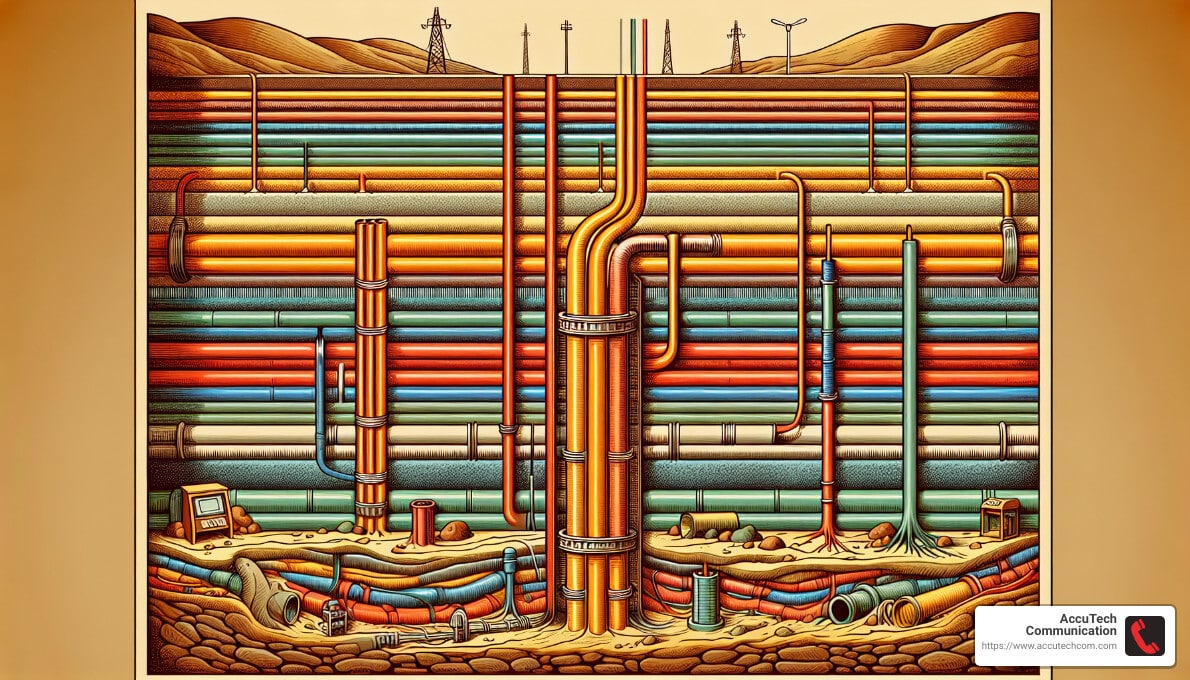

When it comes to installing and protecting electrical systems, underground electrical conduit is an essential component. These conduits serve as protective tubes that house electrical wires, shielding them from moisture, chemical vapors, physical impact, and even animals. This makes them a crucial element in ensuring a safe, efficient, and long-lasting electrical infrastructure.

Quick Facts:

– Material Options: PVC, HDPE, Fiberglass, Metal

– Benefits: Enhanced safety, durability, reduced maintenance

– Depth Requirements: Vary by conduit type and voltage; typically 6-24 inches

The significance of using proper underground electrical conduits cannot be overstated. They ensure electrical safety by minimizing risks of electrocution, short circuits, and fires. Furthermore, selecting the right type of conduit—be it PVC, HDPE, or fiberglass—can make a substantial difference in the performance and lifespan of your electrical systems. Always comply with local codes and regulations to ensure maximum safety and efficiency.

Choosing the Right Underground Electrical Conduit

Selecting the right underground electrical conduit is essential for the safety and longevity of your electrical systems. Here’s a breakdown of the three main types: PVC, Fiberglass, and HDPE conduits.

PVC Conduits

PVC (Polyvinyl Chloride) conduits are a popular choice due to their lightweight nature and cost-effectiveness. They are non-conductive, which means they offer excellent protection against electric shock. Additionally, PVC conduits are durable, weather-resistant, and can withstand moisture, making them ideal for various environments.

- Advantages:

- Cost: PVC conduits are among the least expensive options.

- Weather Resistance: They perform well in various weather conditions.

- Assembly: Easy to assemble using PVC glue, with available fittings, elbows, and connectors.

- Drawbacks:

- Temperature Sensitivity: Not suitable for extreme temperatures (below 20°F or above 140°F).

- Toxic Fumes: Can emit toxic fumes if melted or caught on fire.

Fiberglass Conduits

Fiberglass conduits offer a unique combination of durability and non-conductivity. They are highly resistant to corrosion and can withstand a wide range of temperatures, making them suitable for harsh environments.

- Advantages:

- Non-Conductive: Excellent for electric shock protection.

- Corrosion Resistance: Ideal for environments with chemical vapors or moisture.

- Temperature Tolerance: Can handle extreme temperatures better than PVC.

- Drawbacks:

- Cost: Generally more expensive than PVC conduits.

- Weight: Heavier than PVC, which might make installation slightly more challenging.

HDPE Conduits

HDPE (High-Density Polyethylene) conduits are known for their flexibility and chemical resistance. They are lightweight and easy to install, making them a versatile choice for various underground applications.

- Advantages:

- Flexibility: Can be bent and maneuvered easily, reducing the need for fittings.

- Chemical Resistance: Highly resistant to most chemicals, making them suitable for industrial environments.

- Thermal Resistance: Can withstand significant temperature variations without degrading.

- Drawbacks:

- Cost: More expensive than PVC but generally more durable.

- Installation: Requires specialized tools for proper installation.

Choosing the right underground electrical conduit involves balancing factors like cost, durability, and specific environmental requirements. Whether you opt for PVC, fiberglass, or HDPE, understanding their unique properties will help you make an informed decision.

Next, let’s dive into the installation techniques for underground electrical conduits, covering topics like planning, trenching, and feeding cable.

Installation Techniques for Underground Electrical Conduit

Digging the Trench

Planning is key before you start digging. You need to decide the path for your underground electrical conduit and mark it clearly. Call 811 to have local utility companies mark existing underground utilities to avoid any accidents.

Trencher Use: Renting a gas-powered trenching machine can save you a lot of manual labor. These machines can be rented for less than $200 a day in most places.

Manual Digging: If you prefer manual labor, use a flat trench shovel and a pickaxe. This can be more time-consuming but is cost-effective.

Safety Precautions: Always wear protective gear, including gloves and safety glasses. Be cautious of existing underground utilities and follow local regulations for trench depth.

Laying the Conduit

Once your trench is ready, it’s time to lay the conduit.

Conduit Types: Choose the conduit type based on your project needs. PVC is a popular choice due to its cost-effectiveness and durability.

Depth Requirements: Follow local codes for depth requirements. For example:

– PVC Conduit: Requires a depth of 18 inches.

– Rigid Metal Conduit: Only needs 6 inches.

– UF Cable (without conduit): Needs to be buried at 24 inches.

Sealing: Use exterior-grade acrylic-latex caulk around conduit outlet bodies to seal out water. This is crucial to prevent moisture from entering the conduit and damaging the wires.

Wiring and Connections

Now that your conduit is in place, it’s time to feed the cable and make connections.

Cable Types: Use UF (underground feeder) electrical cable for direct burial or within a conduit. Ensure the cable type matches your project’s voltage requirements.

Connection Techniques:

– Attach a plastic underground electrical conduit outlet body to the end of the conduit.

– Push the UF cable into the conduit and feed it through to the electrical panel.

– Secure the cable using joist hangers and cable staples if needed.

Testing: After laying and connecting the cable, it’s crucial to test the system. Have a licensed electrician make the final connections at the main electrical panel and perform a thorough test to ensure everything is working correctly.

By following these steps, you can ensure a safe and efficient installation of underground electrical conduits. Next, we’ll cover the depth requirements and regulations you need to be aware of.

Depth Requirements and Regulations

6-Inch Installation Option

Local Codes: For installing galvanized rigid metal conduit just 6 inches below the surface, you need to check local codes to ensure compliance. This method is ideal if you have rocky or heavy clay soil that makes digging difficult.

Depth Specifics: The conduit must be buried at least 6 inches deep. This shallow depth requires the use of galvanized rigid metal for maximum protection.

Permit Requirements: Always obtain an electrical permit and have the work inspected. This ensures safety and compliance with local regulations.

Cost and Protection Level: While this method provides superior protection, it comes at a higher cost. Ten feet of 1/2-inch galvanized rigid metal conduit is about $37. Despite the cost, the robust protection it offers makes it a worthwhile investment for short distances.

12-Inch Installation Option

Local Codes: For 12-inch deep installations, GFCI-protected direct-buried Type UF cable can be used. This is often the best choice for small backyard projects.

Depth Specifics: The cable must be buried at least 12 inches deep. The GFCI protection compensates for the shallower depth, enhancing electrical safety.

Permit Requirements: As always, secure a permit and ensure an inspection is done. This not only ensures compliance but also safety.

Cost and Benefits: This option is cost-effective since it eliminates the need for expensive metal conduit. It’s perfect for small projects where minimal digging is required.

18-Inch Installation Option

Local Codes: When choosing to install PVC conduit at 18 inches deep, local codes still apply. This depth is sufficient for most residential projects.

Depth Specifics: The conduit must be buried at least 18 inches deep. This depth is a good balance between protection and ease of installation.

Permit Requirements: Obtain the necessary permits and get the installation inspected to ensure it meets all safety and code requirements.

Future Expansions and Cost Benefits: PVC conduit is affordable and provides room for future expansions. This makes it a cost-effective solution for residential projects, offering good protection without breaking the bank.

24-Inch Installation Option

Local Codes: For deeper installations, a direct-buried Type UF cable at 24 inches is often required. This method provides maximum protection.

Depth Specifics: The cable must be buried at least 24 inches deep. This depth ensures that the cable is well-protected from physical damage.

Permit Requirements: Don’t forget to get a permit and have your work inspected. This step is crucial for ensuring the safety and legality of your installation.

Deeper Trench Benefits and Physical Protection: Burying the cable deeper provides better physical protection. This is especially important in areas with heavy traffic or potential for digging. While the trenching is more labor-intensive, the added protection is a significant benefit.

By following these depth requirements and regulations, you can ensure a safe and compliant installation of your underground electrical conduits.

Maintenance and Troubleshooting Underground Electrical Conduits

Inspections

Regular inspections are crucial for maintaining the integrity of your underground electrical conduit system. Start by checking for signs of wear and tear, such as cracks or corrosion.

Tip: Schedule inspections at least once a year or after any major weather events.

Common Issues

Moisture Ingress: Water can seep into conduits, especially if they aren’t sealed properly. This can lead to short circuits and other electrical issues.

Physical Damage: Conduits can be damaged by digging activities or heavy traffic above ground. This is more common in shallower installations.

Cable Degradation: Over time, cables can degrade due to environmental factors like temperature fluctuations and chemical exposure.

Repair Methods

Sealing Leaks: Use exterior-grade acrylic-latex caulk to seal any gaps or cracks in the conduit. This prevents moisture ingress and protects the cables inside.

Replacing Damaged Sections: If a section of the conduit is damaged, it’s best to replace it. Cut out the damaged section and replace it with a new piece, securing it with appropriate fittings and PVC glue.

Cable Replacement: If the cables inside the conduit are damaged, you’ll need to pull them out and replace them. Use a fish tape to guide the new cable through the conduit.

Note: Always turn off the power at the main electrical panel before attempting any repairs.

Maintaining and troubleshooting your underground electrical conduits ensures long-term reliability and safety. Regular inspections and prompt repairs can save you from costly issues down the line.

Next, we’ll dive into the frequently asked questions about underground electrical conduits.

Conclusion

Long-term Benefits

Investing in underground electrical conduit systems offers many long-term benefits. These include better protection against weather, reduced maintenance costs, and improved aesthetics by eliminating overhead lines. Underground conduits are also less prone to damage from external factors like animals or falling branches, ensuring a more reliable electrical system.

AccuTech Communications

At AccuTech Communications, we specialize in providing top-quality underground electrical conduit solutions. Our team of experts is equipped to handle everything from initial planning to installation and maintenance. With decades of experience, we ensure your project is completed efficiently and safely.

Project Planning

Proper planning is crucial for any underground electrical conduit project. Start by consulting with local authorities to understand permitting requirements and depth regulations. Use a detailed plan to map out your conduit path, considering future expansions and maintenance access points.

By partnering with AccuTech Communications, you can be confident that every aspect of your project will be handled with precision and care. From choosing the right materials to executing the installation, we are committed to delivering exceptional service and reliable results.

Next, we’ll dive into the frequently asked questions about underground electrical conduits.

Frequently Asked Questions about Underground Electrical Conduits

What conduit is best for underground electrical use?

Choosing the right underground electrical conduit depends on your specific needs and environmental conditions. Here’s a quick rundown:

- PVC Conduits: These are lightweight, cost-effective, and weather-resistant, making them a popular choice for many underground applications.

- Fiberglass Conduits: Known for being non-conductive and resistant to corrosion and extreme temperatures, these conduits are ideal for environments with harsh conditions.

- HDPE Conduits: These offer excellent flexibility, chemical resistance, and thermal resistance, making them suitable for long-term underground use.

Each type has its own set of advantages, so the best choice will depend on your specific project requirements.

How deep should electrical conduit be buried?

The depth at which you should bury your electrical conduit varies based on the type of conduit and local building codes. Here are some general guidelines:

- 24 inches deep: Direct-burial underground feeder cable.

- 18 inches deep: THWN-2 conductors inside PVC conduit.

- 12 inches deep: GFCI-protected direct-burial feeder cable.

- 6 inches deep: Galvanized EMT (metal electrical conduit).

Always check local building codes to ensure compliance with regulations.

Is PVC or metal conduit better for underground applications?

Both PVC and metal conduits have their pros and cons for underground use:

- PVC Conduit: Generally preferred due to its lightweight nature, cost-effectiveness, and resistance to corrosion. It’s also easier to work with and install.

- Metal Conduit: Offers superior physical protection but can be more expensive and difficult to install. Types like galvanized EMT can be buried at shallower depths (6 inches) due to their durability.

For most residential and light commercial applications, PVC conduit is often the best choice due to its balance of cost, ease of installation, and durability.

For more information on choosing the right conduit and professional installation services, visit our Innerduct Installation Services page.

By understanding these FAQs, you can make informed decisions about your underground electrical conduit projects. For any further questions or to get started on your project, contact us at AccuTech Communications. We’re here to help!