Fiber Blowing Contractors: Superior 2025 Guide

Why Fiber Blowing Contractors Are Revolutionizing Network Installation

Fiber blowing contractors use a cutting-edge method that pushes fiber optic cables through ducts with compressed air. This technique, also known as air-jetting, is a major leap forward from traditional cable pulling. It offers faster installation, lower cable stress, and future-proof scalability, making it a cost-effective choice for expanding networks without new construction.

Key services include air-blown fiber (ABF) installation, microduct preparation, FTTH/FTTP deployment, fusion splicing, OTDR testing, and 24/7 emergency maintenance.

The demand for high-speed connectivity is surging across all sectors, from healthcare and manufacturing to education. Traditional cable pulling struggles with long distances and future expansion needs, but fiber blowing excels by creating a nearly frictionless environment. As one professional noted, *”The cable blower connects to the duct system… compressed air is added… and the push force then pushes the cable through the duct freely.”

I’m Corin Dolan, owner of AccuTech Communications. Since 1993, my team and I have served Massachusetts, New Hampshire, and Rhode Island, witnessing how this technology makes network installations faster, more reliable, and more affordable for businesses of all sizes.

Quick look at fiber blowing contractors:

What is Fiber Blowing? A Look at the Technology and Process

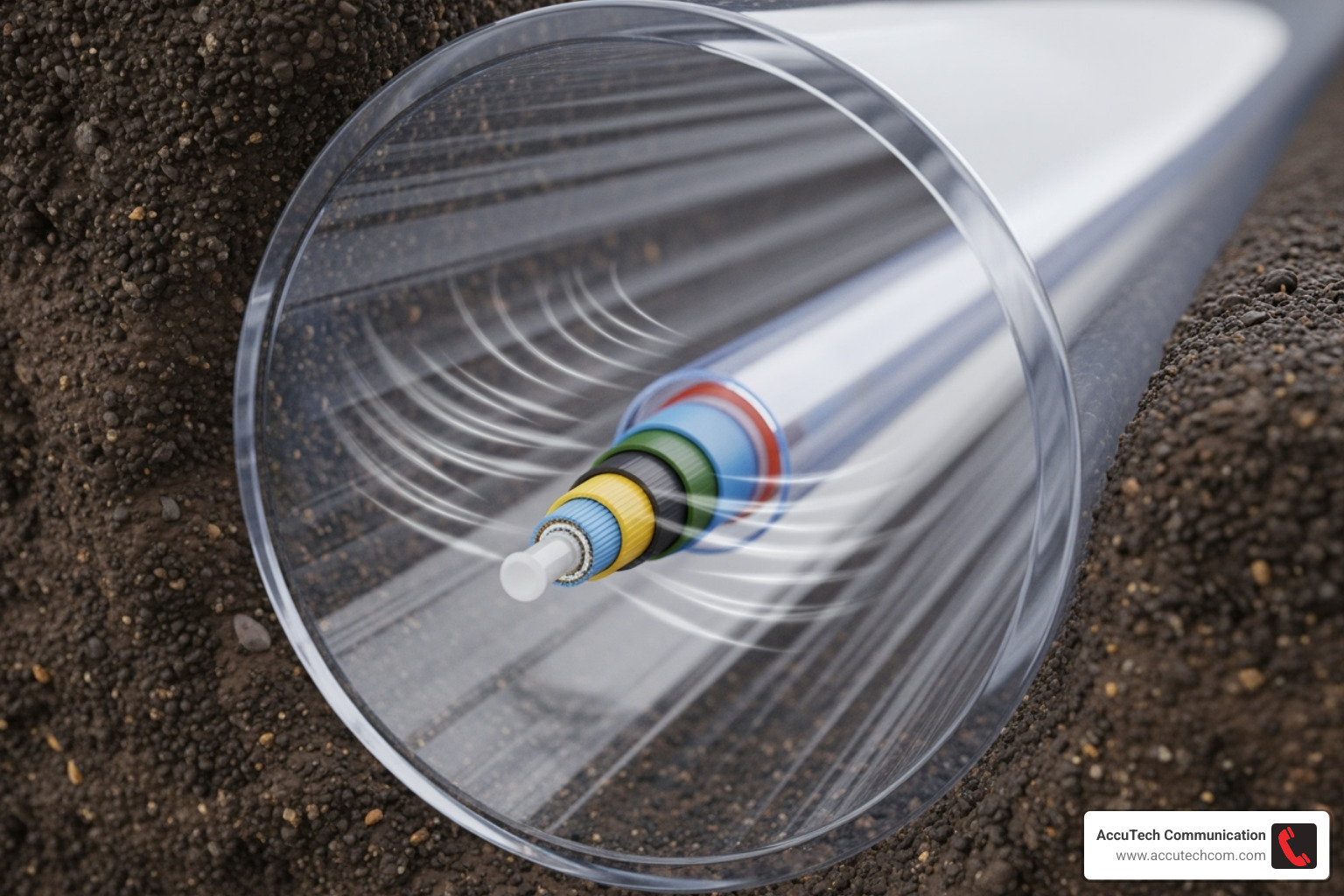

Instead of pulling cables through tight spaces, fiber blowing uses compressed air to create a smooth highway for fiber optic cables. The compressed air forms a cushion around the cable, dramatically reducing friction. This allows the cable to float through the pathway, minimizing stress on the delicate fiber strands and ensuring a more reliable network.

Fiber blowing contractors seal and pressurize a pre-installed microduct system. A pushing force then guides the cable, which rides the air cushion for incredible distances—sometimes several kilometers. This air-jetting method relies on these specially designed microducts to create the perfect installation environment.

For a deeper dive into how we approach these installations, explore our comprehensive guide on Fiber Optic Installation.

The Core Components: Ducts and Cables

A successful fiber blowing project depends on two key components: microducts and specialized cables.

Microducts are small, flexible tubes, typically made from HDPE (High-Density Polyethylene) with smooth inner surfaces to reduce friction. Modern systems like FuturePath bundle multiple pathways into a single sheath, allowing for easy future expansion without new construction.

Air Blown Fiber (ABF) cables are lightweight and feature specialized jackets that glide through ducts with minimal resistance. They are specifically engineered for the blowing process, maintaining integrity over long distances. Learn more about the different types we work with on our page on Types of Fiber Optic Cable.

The “How-To”: A Simplified Installation Workflow

Experienced fiber blowing contractors follow a methodical process for perfect results.

- Site Survey and Planning: We conduct a thorough site survey, including pre-bore-path planning, to map out the most efficient routes and identify challenges. This is a core part of our Fiber Optic Network Design process.

- Duct Installation: Depending on site conditions, ducts are installed via trenching, plowing, or horizontal directional drilling for crossing under roads or waterways.

- Cable Blowing: After verifying duct continuity, we connect our blowing equipment. Compressed air is introduced, and the fiber cable is gently pushed through the duct on a cushion of air. See more details at How to Install Fiber Optic Cable.

- Post-Installation: The final phase includes precision splicing (often fusion splicing) to join cable sections and rigorous testing with advanced tools to verify that every fiber strand meets performance standards.

Key Advantages of Fiber Blowing Over Traditional Installation

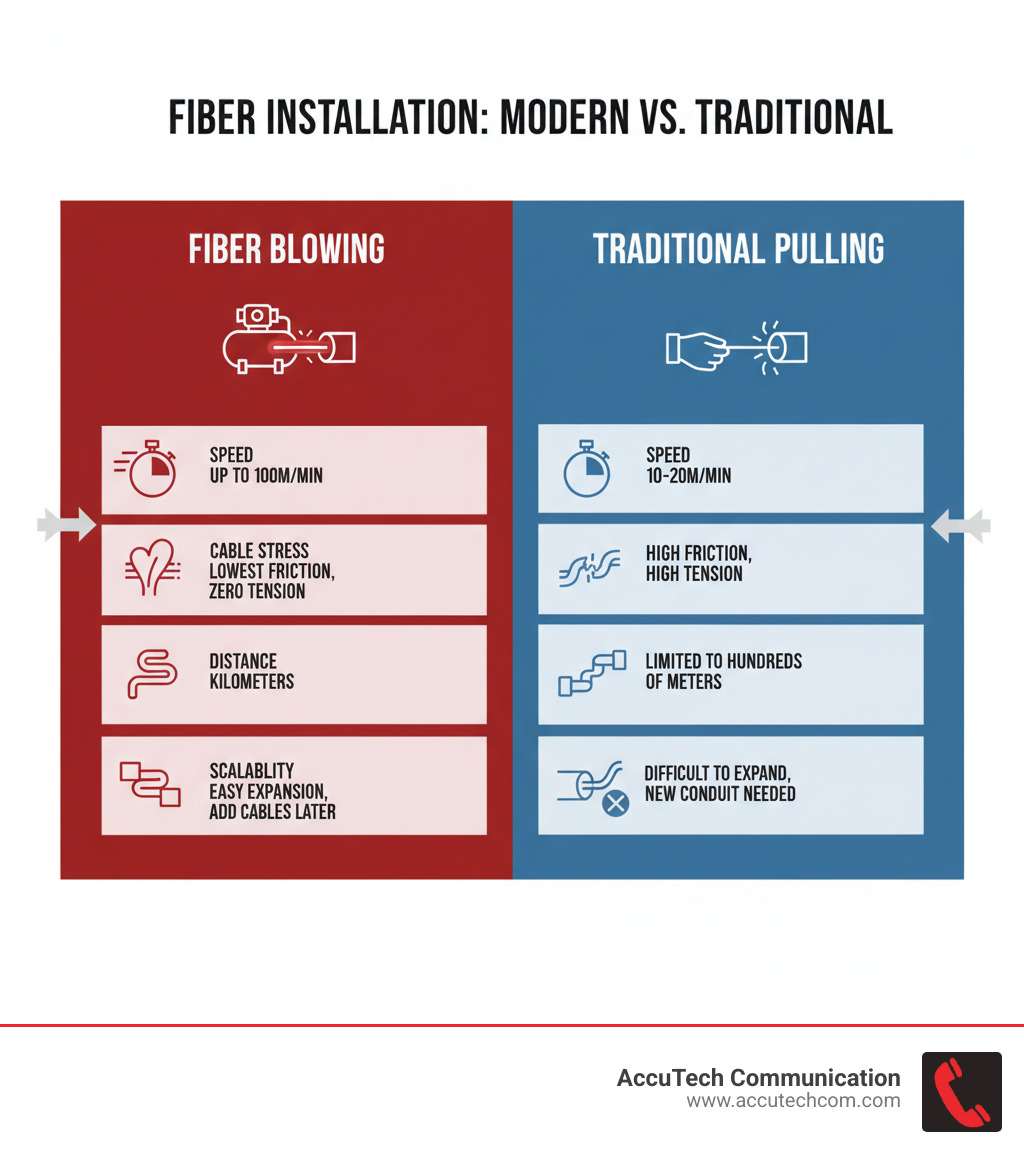

When comparing fiber blowing to traditional cable pulling, fiber blowing contractors deliver superior results across nearly every metric.

| Feature | Fiber Blowing | Traditional Pulling |

|---|---|---|

| Speed | Very fast, kilometers per hour | Slower, limited by friction and manual effort |

| Distance | Long distances (several kilometers) possible | Shorter runs, increased friction over distance |

| Labor | Reduced labor, smaller crews | More labor-intensive, larger crews |

| Cable Stress | Minimal, cable rides on air cushion | High, significant pulling tension |

| Scalability | Excellent, easy to add/upgrade cables | Poor, often requires re-pulling entire conduit |

| Cable Integrity | Preserved, less risk of micro-bends | Higher risk of damage, kinks, or stretching |

| Cost-Effectiveness | Lower long-term costs, especially with MACs | Higher initial cost if frequent upgrades needed |

Speed and Efficiency

Fiber blowing is the express lane for network installation. By eliminating friction, fiber blowing contractors can deploy fiber at speeds measured in kilometers per hour. This speed advantage leads to reduced labor costs and faster project completion times, as cables glide on a cushion of air instead of being dragged.

Minimized Cable Stress

Traditional pulling creates significant pulling tension on fiber optic cables, which can cause micro-bends, kinks, or internal damage that compromises the network over time. Fiber blowing is a gentler approach. The cable experiences virtually no stress as it rides on a cushion of air, preserving its integrity and ensuring improved network longevity.

Future-Proofing and Scalability

Fiber blowing is a smart investment for business growth. Traditional methods require you to predict future capacity needs, often leading to costly re-installations. With microduct systems, you can easily add cables to existing ducts as needed, without new construction or operational disruptions. This cost-effective upgrade capability provides significant long-term savings.

Versatility

Fiber blowing technology is highly adaptable. Fiber blowing contractors can easily steer confined spaces and run long-distance connections of several kilometers, which would be difficult or impossible with traditional methods. The technology is equally effective in dense urban deployments and sprawling rural installations. For more details on complex underground work, visit our page on Underground Fiber Optic Cable Installation.

Services and Selection: What to Expect from Fiber Blowing Contractors

Professional fiber blowing contractors offer more than just cable installation; they provide turnkey solutions for reliable, scalable networks. The best partners manage projects from initial design to final certification.

Key services include:

- Installation: This covers microduct placement via trenching, plowing, or horizontal directional drilling, plus the cable jetting process itself. Contractors are also experts in FTTH and FTTP deployments. See our Fiber Construction capabilities for more.

- Splicing and Termination: Precision is key for Splice Fiber Optic Cable work, typically using fusion splicing. Professionals also handle termination in network enclosures and Fiber Optic Patch Panel installations.

- Testing and Certification: Quality contractors perform comprehensive OTDR testing to measure signal loss and identify issues before the network goes live. The gold standard is 100% OTDR testing on every installation.

- Repair and Maintenance: Look for contractors who offer emergency restoration, often 24/7, to minimize downtime when damage occurs. See a fiber repair job in action.

What Projects are Best for Fiber Blowing Contractors?

Fiber blowing excels in projects where speed, distance, and scalability are critical:

- Long-haul networks connecting distant locations.

- Community fiber projects (FTTH/FTTP) for bridging the digital divide.

- Metro network rings in urban areas requiring easy future upgrades.

- Data center interconnects that demand fast, reliable installation.

- Campus environments (universities, corporate parks) with existing duct infrastructure.

How to Choose the Right Fiber Blowing Contractors

Selecting the right partner is crucial. Here’s what to look for:

- Experience and Reputation: Choose contractors with a long history, positive client testimonials, and a portfolio of successful projects similar to yours.

- Equipment and Technology: Top-tier fiber blowing contractors invest in state-of-the-art blowing machines, precision testing tools, and real-time project monitoring systems.

- Safety and Certifications: Ensure your contractor has a strong safety record and proper licensing. Check our guide on Fiber Optic Cable Contractor License for more information.

- Scope of Services: A full-service contractor who handles everything from design to emergency repairs, including specialized Fiber Optic Splicing Contractors services, simplifies project management and ensures consistent quality.

The Nuts and Bolts: Equipment, Costs, and Common Challenges

A successful fiber blowing operation requires specialized equipment and skilled technicians. Understanding these elements highlights why fiber blowing contractors can achieve such impressive results.

Essential equipment includes:

- Fiber Blowing Machines (Jetting Units): These devices feed fiber into ducts while injecting compressed air at precisely controlled rates.

- Air Compressors: Provide the compressed air needed to create the air cushion, with pressure and flow carefully managed to prevent cable damage.

- Aftercoolers: Remove moisture from the compressed air, which is essential for protecting equipment and ensuring a quality installation.

- Ancillary Tools: This includes duct cutters, cable lubricants, cleaning sponges, and OTDR testers to confirm fiber integrity post-installation. Learn more about How to Test Fiber Optic Cable.

Understanding the Costs of Fiber Blowing

While specific pricing varies, it’s helpful to understand the general cost landscape.

- Equipment Investment: Purchasing a fiber optic cable blower costs around $34,786 on average. Rental options are also available, averaging $267/day, $983/week, or $3,090/month.

- Project Costs: Final costs depend on labor, project complexity, location, and permitting.

- Return on Investment (ROI): Fiber blowing delivers excellent ROI. Faster installation reduces labor hours, and the ability to easily add cables later eliminates the need for expensive civil works for future upgrades, making it a smart long-term investment.

Overcoming Common Installation Challenges

Even with advanced technology, challenges can arise. Experienced fiber blowing contractors are skilled at anticipating and solving them.

- Duct Blockages: Damaged pipes or misaligned connectors are the most common obstacles. Troubleshooting involves verifying continuity with air pressure or cleaning sponges to locate blockages.

- Need for Skilled Technicians: Operating blowing equipment requires specialized training in air pressure dynamics and troubleshooting. The expertise of a Fiber Optic Splicing Technician is crucial for success.

- Systematic Troubleshooting: When issues occur, teams use precise path verification and clear communication to resolve problems efficiently, especially on large projects with multiple subcontractors.

The Evolution and Future of Fiber Installation

The fiber optic industry is constantly evolving, and fiber blowing contractors are at the forefront of this innovation, turning a novel approach into the gold standard for network deployment.

Technology Evolution

Today’s advancements make early installations look primitive. Key developments include:

- Micro-trenching: This minimally invasive technique creates narrow slots for microducts, making it ideal for urban environments by reducing disruption and speeding up installation.

- Higher-Count Cables: Modern cables pack more capacity into smaller packages. We now work with 144- and 288-fiber cables that are smaller than old 12-fiber cables, allowing existing ducts to carry much more data.

- Overblowing Techniques: This impressive development allows us to install new fiber into ducts that already contain cables, enabling rapid network upgrades without new construction.

This journey from basic pulling to sophisticated air-blown systems reflects decades of innovation. Learn more in our guide on Fiber Optic Technology History.

Future Trends

The future of fiber installation promises even greater efficiency and reliability.

- Increased Automation: Next-generation blowing machines will feature sensors that automatically adjust air pressure and feed speed, optimizing performance and reducing human error.

- Smart Monitoring Systems: Real-time monitoring of duct conditions, air pressure, and cable stress will provide immediate feedback, helping to prevent issues and predict maintenance needs.

- Robotics in Installation: Soon, robotic systems may assist with microduct placement in hazardous or hard-to-reach areas, improving safety and efficiency.

As fiber blowing contractors adopt these advances, we can deliver even better value and push the boundaries of network infrastructure for our clients in Massachusetts, New Hampshire, and Rhode Island.

Frequently Asked Questions about Fiber Blowing

Here are answers to the most common questions we receive about fiber blowing technology.

How far can you blow a fiber optic cable?

With modern equipment and ideal conditions, fiber blowing contractors can install a cable for several kilometers in a single run. The maximum distance depends on several factors:

- Duct Condition: Smooth, clean microducts allow for the longest runs.

- Cable Type: Lightweight cables designed for blowing travel farther.

- Air Pressure: Must be optimized—too little won’t provide enough force, while too much can create counterproductive turbulence.

- Bends in Path: Every turn adds resistance and shortens the maximum distance.

Experienced technicians can optimize these variables to make long-haul deployments practical and cost-effective.

Is fiber blowing better than pulling?

In most cases, yes. Fiber blowing is far gentler on the cable, as it dramatically reduces friction and stress. Traditional pulling creates high tension that can cause damage and degrade performance. Blowing is also faster, requires less labor, and is more effective over long distances, resulting in fewer splice points and a more reliable network. While pulling may be suitable for very short runs, blowing is the superior choice for most modern installations, especially those that require future scalability.

What is “jetting” in fiber optics?

“Jetting” is another industry term for fiber blowing. You may also hear “air-assisted installation.” All these terms describe the same process: using high-velocity compressed air to propel a fiber optic cable through a duct. The name comes from the jet-like stream of air that pushes the cable forward. Regardless of the term used, this air-assisted method is a major advance in fiber installation efficiency and reliability.

Conclusion: Partnering for a High-Speed Future

Fiber blowing technology is a game-changer for network infrastructure. Its benefits are clear: remarkable efficiency, impressive scalability, long-term cost-effectiveness, and the ability to future-proof your network. This method minimizes stress on delicate cables, steers challenging environments, and accelerates project timelines.

However, the technology is only as good as the team using it. Partnering with experienced fiber blowing contractors is essential. Their deep expertise, state-of-the-art equipment, and commitment to safety ensure every installation is done right. Rigorous quality assurance, including 100% OTDR testing, guarantees your network will perform as promised.

At AccuTech Communications, we have been providing these services since 1993, helping businesses across Massachusetts, New Hampshire, and Rhode Island build the backbone of their digital future. We combine cutting-edge technology with experienced craftsmanship to deliver solutions for community fiber projects, campus network expansions, and more. We understand that every project is unique and requires a thoughtful approach.

Ready to see how fiber blowing can transform your next network project?

Contact us today to discuss your fiber optic cabling installation needs