Conduit Ethernet Cable: 3 Crucial Safety Tips

Why Use Conduit for Your Network Cabling?

Installing conduit ethernet cable is a smart decision for your business network, offering significant advantages that keep your critical connections safe and reliable.

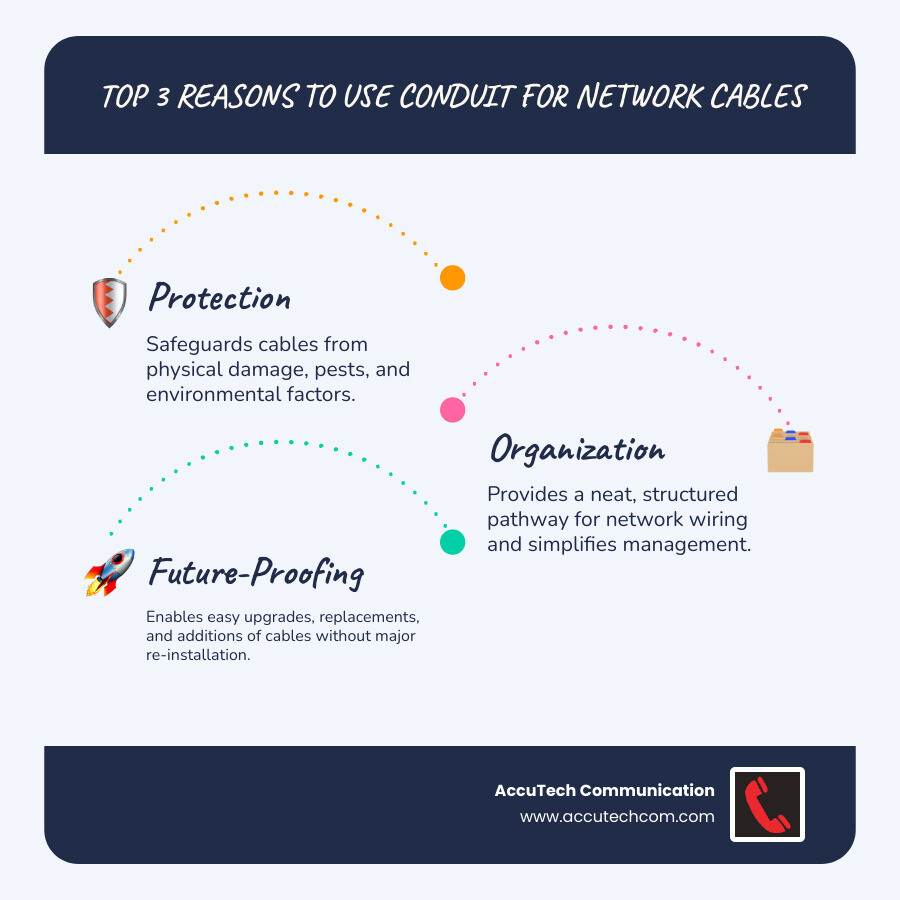

Specifically, using conduit for your Ethernet cables provides:

- Protection: Keeps your cables safe from physical damage, pests, and environmental factors.

- Future-Proofing: Makes it simple to upgrade or replace cables without major re-installation work.

- Organization: Provides a neat, structured pathway for your network wiring.

- Reliability: Contributes to consistent network performance by reducing signal interference and managing heat.

This guide explains why conduit ethernet cable is vital for a robust, long-lasting network infrastructure, covering everything from conduit types to installation best practices.

As owner of AccuTech Communications, I’ve spent years helping businesses implement robust network infrastructures, often relying on conduit ethernet cable solutions to ensure durability and future scalability. We understand the unique communication needs of businesses across Massachusetts, New Hampshire, and Rhode Island, and are committed to modern solutions that align with your goals.

Know your conduit ethernet cable terms:

- does network cable have to be in conduit

- how many network cables in conduit

- burying network cable conduit

Running Ethernet cables in conduit isn’t just about aesthetics; it’s a strategic move that pays dividends. The primary reasons for using conduit ethernet cable are protection, future-proofing, organization, and compliance with industry standards.

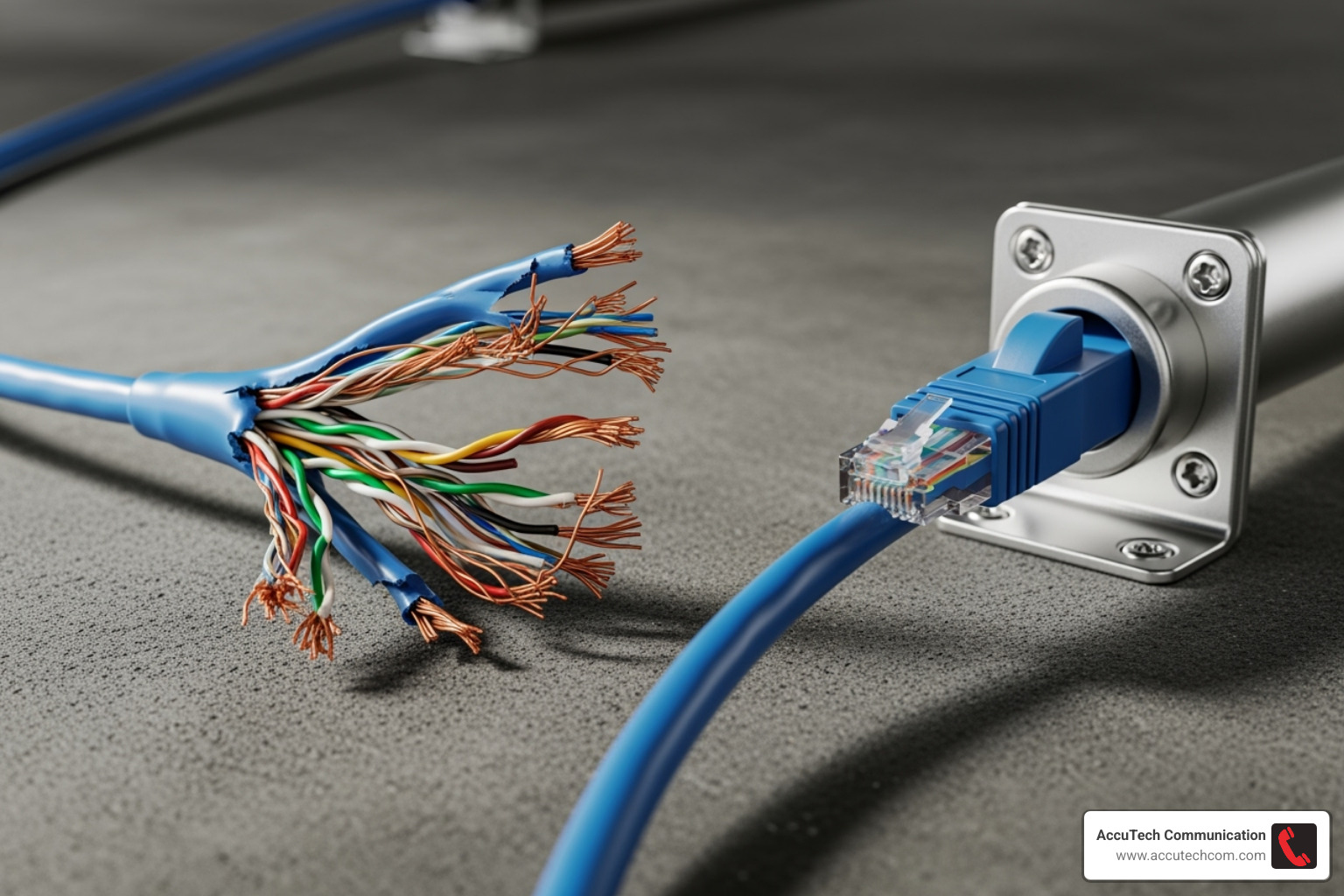

Many Ethernet cable failures, besides termination issues, stem from improper installation, especially when pulling cables. Conduit mitigates many of these risks.

Protection from Damage and Tampering

A compelling reason to use conduit is physical protection. Exposed Ethernet cables are vulnerable to many threats:

- Impact Damage: Dropped tools, moved equipment, or routine maintenance can damage exposed cabling. Conduit acts as a robust shield, absorbing impacts and protecting the delicate wires within.

- Accidental Cuts: In busy environments, cables can be cut during construction or daily activities. Conduit significantly reduces this risk.

- Tampering and Vandalism: For security applications like PoE (Power over Ethernet) cameras, cables are targets for tampering. Metal conduit offers superior vandal resistance over exposed cables or PVC, deterring unauthorized access or damage. Anyone determined enough to cut metal conduit will likely be caught on camera.

- Environmental Hazards: Outdoors, network cables face UV rays, moisture, extreme temperatures, and pests, which can degrade cable jackets and compromise signal integrity. Conduit provides a protective barrier against these environmental factors. For more detailed insights into protecting your outdoor network cables, see our guide on Conduit for Outdoor Network Cable.

- Rodent Protection: Conduit, especially metal, creates an impenetrable barrier against rodents, preventing outages and safeguarding your critical connections.

Future-Proofing Your Installation

Beyond immediate protection, conduit ethernet cable is a cornerstone of future-proof network design. As technology evolves, conduit allows for adaptation without tearing down walls.

- Adding New Cables: Adding a network drop is simple with conduit in place; just pull a new cable through. Without it, you might have to open walls, a costly and disruptive process.

- Replacing Old Cables: When upgrading or replacing a damaged cable, conduit makes it a breeze. Attach the new cable to the old one (or a pull string) and pull it through, saving significant time, money, and effort.

- Pull Strings: A best practice is leaving a pull string in the conduit after installation. This nylon string acts as a guide for future additions or replacements, keeping the pathway ready for upgrades.

- Avoiding Drywall Work: Conduit eliminates the mess and expense of cutting into drywall for new cables, preserving building finishes and reducing labor costs for future network modifications.

- Scalability: Installing conduit with extra capacity builds in scalability, allowing your network to grow with your business without disruptive overhauls. This foresight is why many commercial businesses invest in robust conduit systems.

For more information on how conduit facilitates network expansion and future upgrades, explore What is Innerduct and Why is it Important for Network Cabling Installation?. The principle is similar to innerduct, providing a clear, protected path.

Choosing the Right Conduit for Ethernet Cable

Selecting the right conduit material for your conduit ethernet cable installation is crucial for your network’s performance and longevity. Each type offers different levels of protection.

The three main types are PVC, metal, and flexible conduit. Understanding their strengths and weaknesses will help you choose the best option for your situation.

PVC (Polyvinyl Chloride) Conduit

PVC conduit, the familiar gray tubing seen on construction sites, is popular for its reliability. For many conduit ethernet cable installations, especially residential ones, PVC offers a great balance of cost and performance.

PVC’s affordability is ideal for budget-conscious projects. It’s also easy to work with: lightweight, simple to cut, and joined with solvent cement. Its excellent corrosion resistance makes it perfect for damp basements, underground runs, or moist environments.

However, for commercial installations, there’s a crucial consideration. Industry organizations like BICSI generally don’t recommend PVC for structured cabling inside commercial buildings due to fire safety. PVC can produce toxic smoke when burning, a serious concern for building codes.

For residential installations, direct burial applications, and corrosive environments where metal conduit would eventually surrender to rust, PVC remains an excellent choice. For more insights into conduit applications beyond networking, check out our guide on Conduit for Electrical Wire.

Metal Conduit (EMT, RMC, IMC)

For heavy-duty protection, metal conduit like Electrical Metallic Tubing (EMT), Rigid Metal Conduit (RMC), or Intermediate Metal Conduit (IMC) is the answer. These are the workhorses of commercial installations.

Metal conduit offers superior physical protection that can withstand impacts that would crush PVC. It also provides an equipment grounding path, a significant safety advantage in commercial settings. The fire resistance of metal conduit maintains structural integrity during emergencies, contributing to overall building safety.

Interestingly, while metal conduit shields against external EMI, it can also create an EMI reflection chamber effect. With multiple PoE cables generating heat and interference, the metal can reflect these signals, potentially causing issues. It’s like an echo in a small metal room making conversation difficult.

This EMI reflection concern, along with the higher cost and installation complexity, is why some installers prefer PVC for conduit ethernet cable runs, despite metal’s superior physical protection.

Metal conduit shines in commercial buildings, industrial facilities, and high-traffic areas where maximum physical protection trumps other concerns. For detailed information about professional EMT installation services, explore Enhancing Connectivity: Exploring EMT Piping Service by Accutech Communication.

Flexible Conduit (FMC and ENT)

When cables must steer around obstacles, flexible conduit is the solution. The two main types serve different purposes.

Electrical Nonmetallic Tubing (ENT), or “smurf tube,” offers flexibility in tight spaces. It bends easily around obstacles and is suitable for residential walls or concrete. However, its corrugated interior can make cable pulling more difficult than with smooth-walled conduit.

Flexible Metallic Conduit (FMC) provides physical protection and bendability. However, a critical warning: FMC can “shift and creep” during cable pulls, damaging the cable jacket. This makes it a poor choice for significant conduit ethernet cable installations requiring cable pulling.

Both flexible options are invaluable for complex pathways where rigid conduit would require demolition. However, they are unsuitable for long, straight runs due to friction and potential cable damage. We reserve flexible conduit for short, specific applications where bendability is essential—they are specialty tools, not workhorses.

Key Considerations for Your Conduit Ethernet Cable Installation

Once you’ve chosen your conduit, proper installation is key to performance and longevity. The installation process ensures your network is reliable for years to come.

Adhering to Codes and Signal Integrity

When we install network cabling, we’re building a system that needs to be safe, reliable, and compliant.

First, you must follow the National Electric Code (NEC), or NFPA 70. This is the standard for safe electrical and communications cabling installations. As certified installers in Massachusetts, New Hampshire, and Rhode Island, we adhere to these codes to keep your business safe.

A crucial rule is to never run Ethernet cables in the same conduit as electrical power lines. This is a major fire hazard and guarantees data transmission problems. The electromagnetic interference (EMI) from power lines degrades network signals. Low-voltage data and high-voltage power cables require separate, dedicated pathways.

While modern Ethernet cables with twisted pairs (using differential signaling) are robust, they can struggle with EMI in tight spaces, especially inside metal conduit. Packing too many cables together can amplify interference and slow your network.

Then there’s Power over Ethernet (PoE). PoE cables carry both data and power, simplifying installations for devices like security cameras. However, they generate heat. Bundling too many PoE cables in a conduit can cause heat buildup, which can degrade performance and shorten cable life. We carefully consider cable bundling limits, especially for high-power PoE, to ensure your network performs optimally.

Calculating Fill Ratio for Conduit Ethernet Cable

Stuffing too many cables into a conduit is like overpacking a suitcase; it can cause damage. This is why “fill ratio” is crucial for cable health and future upgrades.

The golden rule for initial installations is the “40% rule”: fill the conduit to only 40% of its capacity. This may seem spacious, but it prevents cables from tangling and allows them to be pulled without excessive force, which can damage jackets and wires. It gives cables room to move freely.

When adding or removing cables from an existing conduit, you can go up to a 60% fill ratio, as the established pathway makes it easier.

The fill ratio depends on the conduit’s interior diameter (trade size) and the cables’ overall diameter (OD). For example, a Cat6 cable has a different OD than a Cat6a. We always use these specific measurements to ensure a proper fit.

Also, consider bend de-rating. Multiple or sharp bends create friction, so we must reduce the cable count to avoid stress during pulling. Using a larger conduit is often smarter if you anticipate multiple bends.

For communications cables, we recommend a conduit no smaller than 3/4″ (trade size). Anything smaller makes pulling difficult and increases the risk of damage.

Here’s a quick look at how many common Cat6 cables (which are about 0.23″ in diameter) fit based on that 40% fill rule. These are ideal maximums – real-world situations, especially with PoE or lots of bends, might mean slightly fewer cables.

| Conduit Size (Trade) | Approx. Internal Diameter (inches) | Max. Cat6 Cables (40% fill) |

|---|---|---|

| 3/4″ | 0.824″ | 5 |

| 1″ | 1.049″ | 8 |

| 1.5″ | 1.61″ | 19 |

| 2″ | 2.067″ | 32 |

Best Practices for Pulling Cable

Pulling Ethernet cable through conduit is an art. Most non-connector cable issues happen during this process due to improper technique, which can easily damage the cable.

Every Ethernet cable has a maximum pulling tension, typically 25 ft/lbs. Exceeding this limit can stretch the internal twisted pairs, degrading the signal and tearing the outer jacket.

Our secret weapon during a pull is cable lubricant. We use a synthetic, wax-based lubricant at the start of the conduit to drastically reduce friction, making the pull smoother and safer for the cable.

For long runs or those with more than two 90-degree bends, we create intermediate pull points (like junction boxes). This allows us to pull the cable in shorter segments, keeping tension low and preventing damage.

And speaking of damage, avoiding jacket damage is paramount.

- We make sure all conduit bends are smooth and gradual. Sharp bends are a nightmare to pull through and can easily kink or stress the cable.

- We use protective sleeves (bushings) on the ends of the conduit. These little plastic guards prevent the cable jacket from getting scuffed or torn as it enters the conduit.

- As the cable feeds in, it’s crucial to prevent it from binding or kinking. This often means having a second person carefully guide the cable into the conduit, ensuring a nice, smooth entry.

A pro tip: always leave a pull string in the conduit after installation. This nylon string serves as a guide for future cable additions or replacements, a simple act of foresight that saves future headaches.

Understanding these careful installation steps is key to having a network that works flawlessly for years. While putting in conduit might seem like an extra upfront cost, the savings you’ll see down the line in easier upgrades, less maintenance, and fewer headaches are truly substantial. For more insights on the financial benefits, check out our guide on Conduit Installation Cost.

Frequently Asked Questions about Conduit for Ethernet

It’s natural to have questions when planning your network cabling, especially when it comes to something as important as conduit ethernet cable installations. We often hear similar queries, and we’re happy to clear things up! Here are some of the most frequent questions we get asked:

Can I run Ethernet and power cables in the same conduit?

Absolutely not. Running low-voltage Ethernet and high-voltage power cables in the same conduit violates the National Electric Code (NEC) and poses serious risks.

The rule is strict because it’s a significant fire hazard. Additionally, the electromagnetic interference (EMI) from power cables corrupts data signals, causing slow speeds and dropped connections. At AccuTech Communication, we always separate low- and high-voltage wiring for safety and performance.

What type of conduit ethernet cable is best for outdoors?

When running network cables outside, you’re battling the elements, so your cable and conduit must be tough.

Use an outdoor-rated Ethernet cable (CMX-rated or direct burial). These have robust jackets (LLDPE or HDPE) to withstand UV rays, moisture, and temperature swings. Some include gel filling or water-blocking tape for extra protection.

Once you have the right cable, it needs a durable, watertight home. PVC conduit is a popular, corrosion-resistant choice for outdoor runs. For maximum physical or rodent protection, especially commercially, galvanized rigid conduit (GRC) is excellent. Buried conduit should be at least 10 inches deep; direct burial cables without conduit should be 18-24 inches deep to protect from digging and ground movement.

For more details on tough cables ready for the outdoors, check out our article on Cat6a Outdoor Ethernet Cable.

What’s the difference between residential and commercial conduit requirements?

Rules for conduit ethernet cable installation differ for homes and businesses, mainly due to fire and safety codes (NEC/NFPA 70) and the scale of the project.

- Commercial Installations: These environments have higher safety standards. You generally cannot use outdoor-rated (OSP) or residential (CMX) cable inside a commercial building without specific measures. If an OSP/CMX cable enters, it must connect to an indoor-rated cable within 50 feet or be sealed in a threaded metallic conduit. Commercial projects almost always use metal conduits (EMT, IMC, RMC) for their superior fire resistance, structural integrity, and grounding. Industry bodies like BICSI typically don’t recommend PVC for indoor commercial structured cabling due to fire and structural concerns.

- Residential Installations: Homes have more flexibility. CMX-rated cable is often acceptable. While metal conduit can be used, PVC conduit is more common due to its lower cost and easier installation, especially for runs between floors or underground. However, fundamental safety rules still apply: respect fill ratios and always keep data cables separate from power lines!

For any installation, the goal is to strike the right balance between protection, performance, and staying compliant with all the necessary codes, creating a safe and reliable network for years to come.

Conclusion

Installing conduit ethernet cable is a smart investment in your network infrastructure, creating a durable and expandable highway for your data.

This guide has shown that conduit is a strategic decision. The protection it offers against physical damage, tampering, and environmental hazards prevents costly downtime. Its future-proofing capabilities mean you can upgrade without tearing open walls as technology or your business grows. The organization and code compliance also ensure your network meets professional standards.

We’ve covered various conduit options: budget-friendly PVC for residential and underground use, robust metal conduit for commercial safety and protection, and flexible options like ENT for specific applications (though not ideal for long pulls).

Technical details are also crucial. Understanding NEC regulations ensures a safe, legal installation, while proper fill ratio calculations prevent cable damage during pulls. Best practices like using lubricant, respecting tension limits, and using pull points ensure a smooth installation.

Since 1993, AccuTech Communications has helped businesses in Massachusetts, New Hampshire, and Rhode Island build reliable networks. We’ve seen how proper conduit ethernet cable installations save clients time, money, and future headaches. It’s satisfying when a client easily adds new network drops years later using the conduit we installed, avoiding the need to cut into finished walls.

While every installation is unique, the fundamentals of proper planning, quality materials, and attention to detail create networks that last. Conduit provides the foundation for reliable, scalable connectivity, whether for a single cable or a complex multi-building network.

For a certified and reliable installation that meets all codes and ensures optimal performance, consider professional network cabling installation services. We’re here to help your business stay connected, safely and soundly – because when your network works seamlessly, you can focus on what you do best.