Underground Fiber Optic Cable Installation: Top 5 Best Practices

The Significance of Underground Fiber Optic Cable Installation

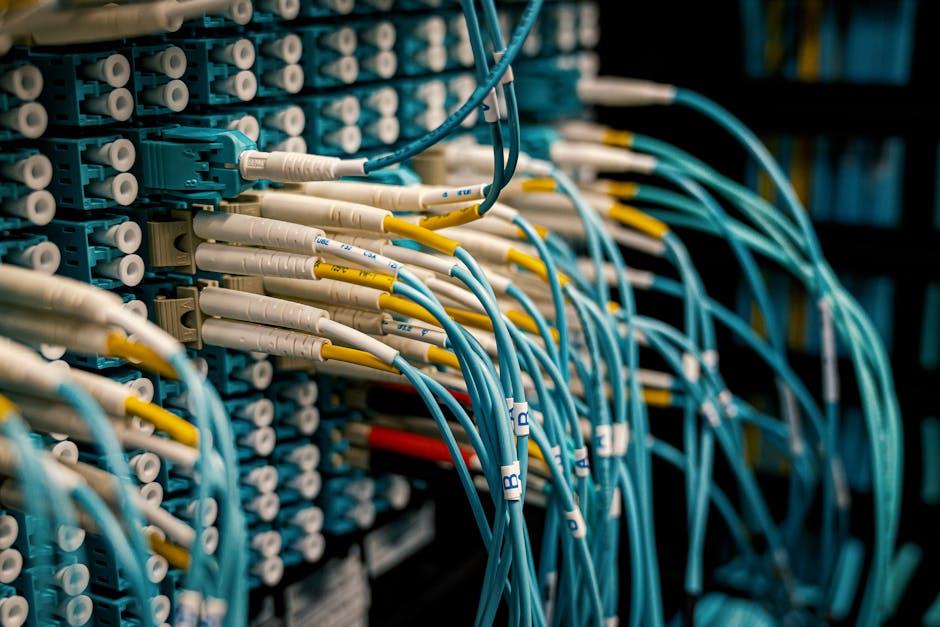

Underground fiber optic cable installation is a pivotal process in establishing reliable and high-speed network connectivity. Robust communication infrastructure is essential for mid-to-large size businesses, especially in healthcare and other critical sectors. So, what should you know about underground fiber optic cable installation from the get-go?

- Overview: Installing these cables means burying them below the ground to protect and enhance signal transmission.

- Importance: It ensures a high level of protection from environmental damage and physical disruptions compared to above-ground methods.

- Benefits: Provides fast, reliable internet and communication services, crucial for uninterrupted business operations and compliance with industry standards.

Understanding the importance of underground fiber optic cable is key for anyone looking to upgrade their network for better performance and reliability.

I’m Corin Dolan from AccuTech Communications, and I bring years of expertise in underground fiber optic cable installation. My focus is on helping businesses like yours achieve seamless, high-performance network solutions.

Let’s delve into the specifics that ensure your installation is done right.

Planning and Designing the Network for Underground Fiber Optic Cable Installation

Using the Right Equipment

Planning an underground fiber optic network starts with a solid design. This involves several critical steps to ensure the installation is both effective and durable.

Network Layout

First, outline the network layout. Determine where the fiber optic cable will enter the system and map out its path. This step is crucial to avoid any unnecessary bends or obstacles that could damage the cable.

Example: In a recent project, our team at AccuTech Communications designed a network layout for a corporate campus. We identified the optimal entry points and mapped a path that minimized bends and avoided high-traffic areas to reduce the risk of future damage.

Minimum Bend Radius

Fiber optic cables are sensitive to bends. Each cable has a minimum bend radius, which is the smallest curve the cable can handle without damage. Exceeding this radius can cause signal loss or even break the fibers.

Plan the cable path carefully. Consider the terrain, existing underground utilities, and potential obstacles. The goal is to create a straightforward route that minimizes risks.

Example: In one of our installations, we navigated around existing gas and water lines by planning a route that kept our fiber optic cables at a safe distance. This careful planning prevented any potential interference or damage.

Using the Right Pulling Equipment

Fiber optic cables require specific pulling equipment to handle their delicate nature. Tools like pulling grips, swivels, and hydraulic pressure relief valves are essential. These tools help manage the pulling tension and prevent cable damage.

Tip: Always use a swivel pulling eye to connect the pull rope to the cable. This prevents the cable from twisting during the pull, which can cause stress and damage.

Trenching Tools

Trenching is the process of digging a path for the conduit that will house the fiber optic cable. The tools and techniques used can vary based on soil type and depth requirements.

- Trenching Machines: These are used for digging the trench. The type of machine depends on the soil and the required trench depth.

- Conduit Placement Tools: These tools help lay the conduit in the trench. Proper placement is crucial to protect the cable from environmental factors and physical damage.

Example: For a recent installation in rocky terrain, we used specialized trenching machines that could handle the tough soil. This ensured a smooth trenching process and a secure conduit placement.

By focusing on these key areas—network layout, minimum bend radius, path planning, pulling equipment, and trenching tools—you can ensure a successful underground fiber optic cable installation.

Next, we’ll explore the techniques and strategies for trenching and conduit placement to protect your fiber optic cables.

Trenching Techniques for Underground Fiber Optic Cable Installation

Conduit Placement Strategies

Trenching for underground fiber optic cable installation involves careful planning and execution. The goal is to create a stable environment for the cables, protecting them from damage and ensuring optimal performance.

Excavation Methods: The trenching process starts with excavation. Depending on the soil type and terrain, different methods are used. For example, in rocky areas, specialized trenching machines can handle tough soil, ensuring a smooth trenching process.

Soil Types and Depth Considerations: The type of soil affects the trenching technique and the depth at which the conduit is laid. In softer soils like clay or loam, trenches can be dug more easily and to the required depth of 1-1.2 meters (3-4 feet). In hard rock conditions, trench depth might be reduced, but additional protective measures like concrete slabs are needed.

Protection and Environmental Factors: The conduit protects the fiber optic cables from environmental factors such as moisture, temperature changes, and physical damage. In areas prone to frost, cables may need to be buried deeper to avoid frost penetration. Using conduits made of robust materials like PVC ensures long-term protection.

Physical Damage Prevention: Preventing physical damage during and after installation is crucial. Conduits must be strong enough to withstand potential damage from surface activities. Additionally, conductive marker tape is often buried above the conduit to help locate the cable during future digs and to warn anyone digging in the vicinity.

Case Study: In a recent project in a suburban area, we encountered mixed soil types. We used a combination of traditional trenching and directional boring to navigate around existing utilities like water and gas lines. This approach minimized disruption and ensured the safe placement of the conduit.

By considering these trenching techniques and conduit placement strategies, you can ensure the protection and longevity of your underground fiber optic cable installation.

Next, we’ll discuss the methods for laying and protecting fiber optic cables underground to maintain their integrity and performance.

Laying and Protecting Fiber Optic Cables Underground

Direct Burial vs. Conduit Use

When it comes to underground fiber optic cable installation, there are two primary methods: direct burial and using conduit. Each has its own set of handling techniques and protective measures to ensure the cable’s longevity and performance.

Direct Burial

Direct burial involves laying the fiber optic cable directly in the ground without conduit. This method is common in rural areas where the risk of physical damage is lower. Here’s how to handle it:

- Plowing Equipment: Specialized plowing equipment is often used. This equipment digs a narrow trench and lays the cable simultaneously, making it efficient for long distances.

- Protective Metallic Components: Fiber optic cables designed for direct burial usually come with protective metallic components. These components shield the cable from environmental factors like moisture and rodent activity.

- Sharp Bends Avoidance: It’s crucial to avoid sharp bends during installation. The minimum bend radius should always be maintained to prevent damage to the fiber.

Using Conduit

In urban or suburban areas, using conduit is often recommended. This method offers extra protection and makes future maintenance easier.

- Cable Pulling: When pulling the cable through the conduit, use a pulling grip and monitor the pulling tension closely. Tools like pulling tape can help ensure the cable isn’t damaged during the process.

- Handling Techniques: Handle the fiber optic cable with care to avoid any kinks or sharp bends. Use appropriate tools to guide the cable smoothly through the conduit.

- Environmental Impact: Conduits protect the cable from environmental elements like water and soil pressure. This is particularly important in areas with varying soil types and conditions.

Environmental Considerations

Whether you choose direct burial or conduit, consider the environmental impact:

- Soil Type: Different soil types require different handling techniques. For instance, rocky soil might necessitate additional protection for the cable.

- Depth: Ensure the cable or conduit is buried at a sufficient depth to avoid damage from surface activities like digging or construction. Local regulations often dictate the minimum depth requirements.

By understanding the differences between direct burial and conduit use, and paying attention to handling techniques and environmental considerations, you can ensure a successful underground fiber optic cable installation.

Next, we’ll delve into splicing, termination, and testing to ensure your network is set up for optimal performance.

Splicing, Termination, and Testing in Underground Fiber Optic Cable Installation

Ensuring Longevity and Performance

Once the fiber optic cables are laid underground, the next critical steps are splicing, termination, and testing. These steps ensure the network’s longevity and performance.

Fusion Splicing

Fusion splicing involves joining individual fibers using heat to fuse them together. This method ensures minimal signal loss and high reliability. The process requires precise alignment of the fibers, often achieved using specialized splicing machines.

Example: In a citywide fiber optic network upgrade, fusion splicing was crucial for maintaining high-speed internet across multiple neighborhoods. The splices were housed in protective enclosures to shield them from environmental factors.

Cable Termination

Cable termination involves connecting the fiber optic cables to devices like switches or routers. Proper termination ensures that the signal can travel efficiently from the cable to the network equipment. This step usually involves using connectors that match the equipment specifications.

Tip: Always follow the manufacturer’s guidelines for cable termination to avoid signal loss and ensure a secure connection.

Network Verification

After splicing and termination, verify the network’s performance. Testing and verification involve using tools like Optical Time-Domain Reflectometers (OTDRs) and power meters. These devices measure signal strength, detect losses, and identify any issues.

Fact: According to industry standards, testing should be done at 1550nm wavelength, as it best shows stress losses in the fiber.

Conduit Utilization

Using conduits can significantly enhance the longevity of underground fiber optic cables. Conduits provide an extra layer of protection against physical damage and environmental factors.

Example: In a residential development project, conduits were used to protect the cables from ground movement and moisture, ensuring a stable and reliable network.

Buffer Tube Protection

Buffer tubes encase the optical fibers within the cable, providing additional protection. They help maintain the integrity of the fibers by shielding them from mechanical stress and environmental conditions.

Tip: Regularly inspect buffer tubes for any signs of wear or damage to ensure ongoing protection.

Integrity Maintenance

Maintaining the integrity of the fiber optic network involves regular inspections and timely repairs. Documenting the installation process, including splicing details and cable routes, can aid in future maintenance.

Fact: Regular inspections can help identify potential issues like cable stress or environmental degradation before they become significant problems.

By focusing on these crucial steps—fusion splicing, cable termination, network verification, conduit utilization, buffer tube protection, and integrity maintenance—you can ensure a robust and high-performing underground fiber optic network.

Next, we’ll explore the challenges and solutions in underground fiber optic cable installation.

Challenges and Solutions in Underground Fiber Optic Cable Installation

Installing underground fiber optic cables is not without its challenges. From accessing tricky locations to managing trench work and ensuring careful cable pulling, each step requires precision and planning.

Effective Solutions for Complex Installation Scenarios

Location Accessibility

Accessing installation sites can be tough, especially in densely populated or geographically complex areas. For example, in urban settings, navigating around existing infrastructure like water and gas lines is crucial.

Solution: Strategic Planning is key. Before starting, thoroughly assess the site. Use detailed maps and GPS technology to plan the best route and avoid existing utilities.

Trench Work

Digging trenches can be challenging, particularly in rocky or uneven terrain. The trenching process must also comply with local regulations regarding depth and safety.

Solution: Advanced Trenching Techniques like horizontal directional drilling (HDD) can minimize surface disruption. HDD is especially useful in areas with many obstacles or where traditional trenching isn’t feasible.

Cable Pulling Challenges

Pulling fiber optic cables through ducts or conduits without damaging them is critical. Excessive pulling tension or sharp bends can harm the delicate fibers.

Solution: Careful Cable Pulling involves using the right tools, such as pulling grips and tension monitors. Monitoring pulling tension helps prevent damage. Additionally, using lubricants can reduce friction and make the process smoother.

Strategic Planning

Before any physical work begins, a comprehensive plan is essential. This includes determining the cable’s path, calculating the minimum bend radius, and selecting the appropriate equipment.

Solution: Detailed Route Planning can help in identifying potential obstacles. Use specialized software to design the network layout, ensuring optimal performance and compliance with industry standards.

Advanced Trenching

Traditional trenching methods might not always be suitable, especially in sensitive or high-traffic areas.

Solution: Modern Equipment and Techniques like micro trenching can be employed. Micro trenching creates narrower trenches, reducing surface disruption and speeding up the installation process. However, it is crucial to consider the local climate, as seen in the Google Fiber case in Louisville, where shallow trenching led to network failures.

Careful Cable Pulling

Ensuring the integrity of the fiber optic cables during installation is paramount.

Solution: Using Specialized Pulling Equipment such as pulling grips and tension meters ensures that the cables are not subjected to excessive force. Monitoring the tension and using appropriate lubricants can prevent damage and ensure smooth cable pulling.

By addressing these challenges with strategic planning, advanced trenching techniques, and careful cable pulling, you can overcome the complexities of underground fiber optic cable installation.

Next, we’ll delve into understanding burial depth requirements and regulations.

Understanding Burial Depth Requirements and Regulations

Proximity to Other Services

When installing underground fiber optic cables, understanding and adhering to burial depth requirements is crucial. Several factors influence these requirements, and they are guided by established standards to ensure the cable’s longevity and functionality.

Factors Influencing Burial Depth:

- Soil Type: The composition and stability of the soil play a significant role in determining the appropriate burial depth. Different soil types, such as clay, sand, and loam, have varying load-bearing capacities and water absorption rates, which can affect cable stability.

- Location and Environmental Conditions: The location’s environmental factors, like soil type, likelihood of ground disturbance, and climate, significantly determine the burial depth. For example, areas prone to frost heave might require deeper burial to prevent cable damage.

- Proximity to Other Utilities: Other underground services, such as water, gas, and electrical lines, impact how deep the fiber cable can be safely installed. Maintaining a safe separation distance is crucial to prevent interference or accidental damage during future utility maintenance or repairs.

- Type of Underground Cable: The specific fiber optic cable type impacts the recommended burial depth. Some cables might require deeper burial for protection, while others are designed to withstand shallower placements.

Regulatory Compliance:

- Local Regulations: Local building codes and regulations often specify the minimum burial depth requirements for fiber optic cables. These regulations ensure the cable’s safety, protection from accidental damage, and adherence to industry standards.

- Industry Standards: Industry standards provide guidelines on optimal burial depths for different types of fiber optic cables. Typically, burial depths range from 18 to 36 inches, but always consult local regulations for specific requirements.

Safety Measures:

- Proximity to Other Services: When planning the installation, always consider existing underground utilities. For instance, water and gas lines need to be clearly marked and avoided to prevent accidents. Electrical lines, in particular, require careful planning to avoid electromagnetic interference.

- Using Conduits: Burying fiber optic cables in conduits is often recommended, especially in areas prone to ground disturbance. Conduits provide extra protection for the cable, reducing the risk of damage and service interruptions.

- Proper Grounding: Grounding is essential for the safety and performance of buried fiber optic cables. Grounding kits specifically designed for armored cables help establish a reliable electrical connection and dissipate any potential electrical charges or surges.

By understanding these factors and adhering to regulations, you can ensure a successful and compliant underground fiber optic cable installation.

Next, we’ll answer some frequently asked questions about underground fiber optic cable installation.

Frequently Asked Questions about Underground Fiber Optic Cable Installation

How deep should the cable be buried?

The burial depth for fiber optic cables typically ranges from 18 to 36 inches. The exact depth depends on a variety of factors, such as soil type, environmental conditions, and local regulations. For instance, in Alberta, the standard minimum depth is 18 inches. Source

Local regulations and industry standards should always be consulted to ensure compliance and protect the cable from potential damage.

Is conduit necessary for fiber optic cables?

Burying fiber optic cables in conduit is highly recommended, especially in areas prone to ground disturbances. Conduits provide extra protection, reducing the risk of damage and service interruptions. In England, for example, fiber is often buried in a duct and blown through the tube, offering enhanced protection. Source

What is the typical duration for installing underground fiber optic cables?

The time required to install underground fiber optic cables varies based on the project’s scale, terrain, and complexity. Small projects might take a few days, while larger installations can span several weeks or more. For example, a fiber installation in a neighborhood took about three months from initial trenching to service availability. Source

Understanding these FAQs can help you better prepare for your underground fiber optic cable installation. For more detailed insights and tailored solutions, reach out to AccuTech Communications.

Conclusion

Underground fiber optic cable installation is a complex but essential task for ensuring reliable and high-speed connectivity. From initial planning and trenching to laying and testing the cables, each step requires careful attention and adherence to best practices.

Review

In this guide, we’ve covered the crucial aspects of underground fiber optic cable installation:

- Planning and Designing: We discussed the importance of thorough site surveys, network layout planning, and using the right equipment.

- Trenching Techniques: We explored different excavation methods, soil types, and depth considerations.

- Conduit Placement: We highlighted strategies for protecting cables against environmental factors and physical damage.

- Cable Laying and Protection: Proper handling techniques and the importance of avoiding sharp bends were emphasized.

- Splicing, Termination, and Testing: We covered fusion splicing, cable termination, and network verification.

- Challenges and Solutions: We provided effective solutions for common challenges like location accessibility and trench work.

- Regulatory Compliance: We explained the importance of adhering to industry standards and regulations.

Best Practices

Here are some best practices to ensure a successful underground fiber optic cable installation:

- Conduct Thorough Site Surveys: Assess terrain, soil conditions, and existing utilities.

- Use Quality Equipment: Employ reliable trenching tools and pulling equipment.

- Follow Manufacturer Guidelines: Adhere to the specific recommendations for handling and installing fiber optic cables.

- Implement Conduit Systems: Use conduits for added protection and ease of maintenance.

- Test and Verify: Conduct rigorous testing using tools like OTDR to ensure the integrity of the installation.

Contact AccuTech Communications

For expert guidance and tailored solutions in Massachusetts, New Hampshire, and Rhode Island, contact AccuTech Communications. Our team of skilled technicians and engineers is committed to delivering high-quality underground fiber optic cable installations that meet your specific needs.

Whether you’re planning a large-scale city upgrade or a residential development, we have the experience and expertise to ensure your project is a success. Reach out to us today for a consultation and let us help you build a robust and reliable communication infrastructure.