Fiber Optic Installation: 5 Essential Steps for Success

Fiber Optic Installation is the cornerstone of today’s fast and reliable high-speed internet infrastructure. Here’s what you need to know if you’re considering installing fiber optics:

- Why Choose Fiber Optics?: Faster and more reliable than traditional copper cables, with reduced interference.

- Installation Process Overview: Typically involves planning, choosing correct cables, and precise installation.

- Benefits: Supports higher bandwidth and speed, offering seamless communication for businesses.

Fiber optics technology has become essential for businesses needing robust communication networks. It powers everything from internet to television and phone services, making it vital to modern infrastructure.

I’m Corin Dolan. With over two decades running AccuTech Communications, I’ve led fiber optic installations across various industries, ensuring businesses experience the full potential of this technology. Now, let’s dig deeper into understanding different types of fiber optic cables essential for your installation.

Understanding Fiber Optic Cables

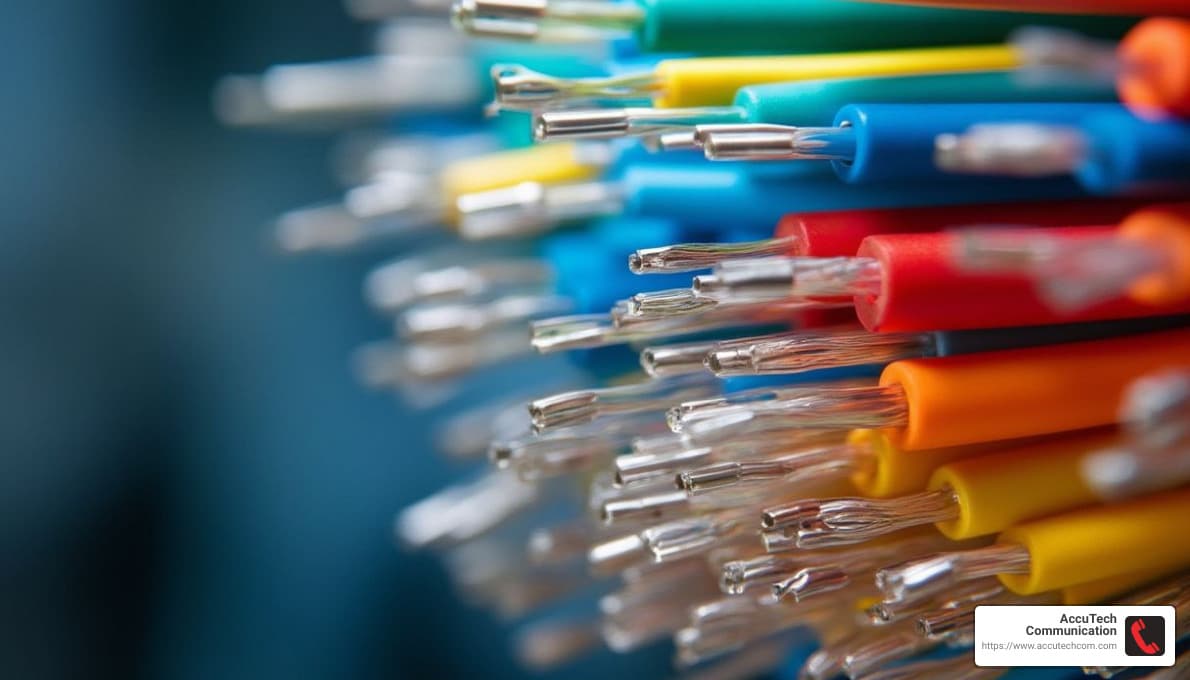

When it comes to Fiber Optic Installation, understanding the different types of cables is crucial. Fiber optic cables are the backbone of modern communication systems, providing the speed and reliability that businesses and homes need. Let’s break down the essentials.

Types of Fiber Optic Cables

Fiber optic cables are mainly categorized into two types: single-mode and multi-mode. These types differ in design and application.

- Single-Mode Fiber:

- Best for Long Distances: Single-mode fiber has a smaller core diameter, allowing light to travel directly down the fiber. This minimizes signal loss, making it ideal for long-distance transmissions.

- Higher Bandwidth: It supports higher bandwidths, which means faster data speeds over longer distances.

- Cost Considerations: Generally more expensive due to the precision required in its production and installation.

- Multi-Mode Fiber:

- Best for Short Distances: With a larger core, multi-mode fiber allows multiple light paths, making it suitable for shorter distances.

- Cost-Effective: Typically less expensive than single-mode fiber, making it a popular choice for local area networks (LANs) and data centers.

- Versatility: Used in various applications like video surveillance and audio-visual installations.

Material Composition

Fiber optic cables can also be distinguished by the materials used in their construction:

- Glass Fibers:

- High Performance: Most common in telecommunications due to their ability to carry signals over long distances with minimal loss.

- Durability: More resistant to environmental changes and physical stress.

- Plastic Fibers:

- Flexibility: Easier to handle and install, often used in consumer electronics and automotive applications.

- Shorter Range: Generally used for shorter distance communications due to higher attenuation.

Key Benefits of Fiber Optic Cables

- Exceptional Bandwidth: Both single-mode and multi-mode fibers offer significantly higher bandwidth compared to copper cables.

- Reduced Interference: Immune to electromagnetic interference, providing more reliable data transmission.

- Lightweight and Thin: Easier to install and manage, making them a practical choice for both commercial and residential settings.

Understanding these different types of fiber optic cables is the first step in planning a successful Fiber Optic Installation. Choosing the right cable type ensures that your network will meet your specific needs, whether it’s for a sprawling corporate campus or a small business office.

Essential Tools and Equipment for Fiber Optic Installation

When you’re ready to start a Fiber Optic Installation, having the right tools and equipment is crucial. These tools ensure that the installation is done correctly and efficiently, minimizing the risk of errors and future repairs.

Fiber Optic Cable

The fiber optic cable is the star of the show. It’s the medium through which data travels as light pulses. Different types of cables, like single-mode and multi-mode, are used based on the distance and bandwidth requirements. Always opt for high-quality cables to ensure optimal performance and longevity.

Connectors

Connectors are essential for joining fiber optic cables to other cables or devices. They need to be aligned perfectly to avoid signal loss. Using connectors from reputable manufacturers is key, as low-quality connectors can lead to poor performance.

Splicing Equipment

Splicing equipment is used to join two fiber optic cables together. This is important when you need to extend the cable or repair a section. Splicing is a delicate process that requires precision to maintain signal integrity. Tools like fusion splicers are commonly used for this task.

Fiber Optic Cleaver

A fiber optic cleaver is a tool that precisely cuts the fiber optic cable. A clean cut is vital for effective splicing. A high-quality cleaver ensures that the fibers are cut at the correct angle, minimizing signal loss during splicing.

Fiber Optic Microscope

A fiber optic microscope is used to inspect the ends of the fiber optic cables. This tool helps in checking the cleanliness and alignment of the fibers before and after splicing. Proper inspection ensures that the connection is free from dirt and defects, which can degrade performance.

Additional Tools

Depending on the specific installation requirements, you might need other tools like:

- Cable Strippers: For removing the protective outer jacket of the cable without damaging the fibers.

- Cable Ties: To organize and secure cables, preventing physical damage.

- Drills and Hammers: For securing cables in place, especially in building installations.

Having these tools and equipment ready will set you on the right path for a successful Fiber Optic Installation. They are essential for ensuring that the installation is done with precision and care, leading to a reliable and high-performance network.

Next, we’ll dive into the step-by-step guide to installing fiber optic cables, covering everything from planning to testing.

Step-by-Step Guide to Fiber Optic Installation

Once you have all the necessary tools and equipment, it’s time to start the Fiber Optic Installation. Follow these steps to ensure a smooth and efficient process.

Planning

First, plan the path for your fiber optic cable. Choose the most direct route from the origin to the destination. Consider any obstacles, such as walls or furniture, and plan how to steer around them. That fewer splices and connectors mean better performance. So, try to keep the cable path as straightforward as possible.

Splicing

If your installation requires connecting multiple sections of fiber optic cable, you’ll need to splice them together. Use the fiber optic cleaver to cut the fibers accurately. Then, use splicing equipment to join them. This step is crucial for maintaining signal strength, so take your time to ensure precision.

Connecting

Next, connect the fibers to their respective connectors. Use a fiber optic microscope to carefully align the fibers with the connectors. Follow the manufacturer’s instructions closely to avoid misalignment, which can lead to signal loss. Secure the connectors firmly to ensure a stable connection.

Organizing

Once the cables are connected, organize them neatly. Use cable ties to secure the cables and prevent them from being damaged. Proper organization not only protects the fibers but also makes future maintenance easier. Keeping the installation tidy is key to maintaining performance and avoiding costly repairs.

Testing

Finally, test the fiber optic connection to ensure it’s working correctly. Use a fiber optic tester to check the signal strength and stability. A thorough test will help you identify any issues early on, allowing you to fix them before they become bigger problems. This step is vital for ensuring a reliable and high-speed network.

By following these steps, you can complete a successful Fiber Optic Installation. Each step plays a crucial role in ensuring that the installation is efficient and effective, leading to a robust and high-performance network.

Next, we’ll explore the costs associated with fiber optic installation, helping you plan your budget effectively.

Fiber Optic Installation Costs

When planning for Fiber Optic Installation, understanding the costs involved is crucial. Here’s a breakdown of what you can expect:

Cost Per Mile

Fiber optic installation costs can vary greatly depending on the project. On average, the cost to install fiber optic cable ranges from $1 to $6 per linear foot. This means that for a mile of fiber optic cable, you might spend anywhere from $5,280 to $31,680.

Installation Cost

The overall installation cost includes not only the cable itself but also the expenses for connectors, splicing, and labor. For a commercial building with 100-200 drops, the installation could cost between $15,000 and $30,000. While this might seem steep, the benefits of high-speed, reliable internet often outweigh these initial costs.

Underground vs. Aerial

Whether the installation is underground or aerial can also impact the cost.

- Underground installation typically costs more due to the need for trenching and additional protective measures. This method is often chosen for its durability and reduced risk of damage from environmental factors.

- Aerial installation, on the other hand, is generally less expensive as it involves hanging the cables on poles. However, aerial cables can be more susceptible to weather-related damage.

Both methods have their pros and cons, so consider your specific needs and environment when making a decision.

Understanding these cost factors will help you plan your budget effectively. Next, we’ll dive into some frequently asked questions about fiber optic installation to further guide you in your decision-making process.

Frequently Asked Questions about Fiber Optic Installation

How is fiber-optic installed?

Fiber optic installation begins with selecting the right type of cable for your needs. You’ll choose between single-mode and multi-mode cables, depending on the distance and bandwidth required. Once you’ve chosen the cable, the outer jacket and inner coating need to be stripped using a fiber optic cleaver for precise cutting.

Next, the cable is run through the planned path, whether underground or aerial, and connected to the appropriate termination points. It’s essential to follow the manufacturer’s instructions carefully to ensure a successful installation. Hiring a professional contractor can simplify this process and ensure that everything is done correctly.

What is needed to install fiber optic Internet?

To install fiber optic internet, you’ll need several essential tools and equipment. These include:

- Fiber optic cables: Choose between single-mode and multi-mode based on your needs.

- Connectors: These are crucial for linking cables to devices.

- Splicing equipment: Used for joining fiber optic cables.

- Fiber optic cleaver: For precise cutting of the cable ends.

- Fiber optic microscope: To inspect the quality of splicing and connections.

Additionally, a well-thought-out plan and adherence to safety practices are vital for a smooth installation process.

How much does it cost to install fiber optic cable?

The cost of installing fiber optic cable can vary widely. On average, you can expect to pay between $1 and $6 per linear foot, translating to $5,280 to $31,680 per mile. For a commercial building with 100-200 drops, the total installation cost can range from $15,000 to $30,000, accounting for cable, connectors, splicing, and labor.

The method of installation also affects the cost. Underground installation tends to be more expensive due to trenching and protection requirements. Aerial installation is usually cheaper but more vulnerable to weather-related damage.

Understanding these costs and what the installation entails will help you make informed decisions about your fiber optic setup. Now, let’s explore how AccuTech Communications can assist you with certified service and competitive pricing.

Conclusion

At AccuTech Communications, we pride ourselves on delivering certified service, competitive pricing, and an unwavering commitment to quality in fiber optic installation. Serving businesses across Massachusetts, New Hampshire, and Rhode Island since 1993, our team of skilled technicians ensures your network infrastructure is optimized for peak performance.

Our certified services mean you can trust us to handle your fiber optic needs with precision and expertise. We understand that every business has unique requirements, and we tailor our solutions to meet those needs effectively.

Competitive pricing is at the heart of our business. We believe that quality service should be accessible, and we strive to offer solutions that fit within your budget without compromising on quality. Our long-standing relationships with clients are a testament to the value we provide.

Quality commitment is more than just a promise—it’s our way of doing business. From planning and installation to maintenance and support, we ensure every step is executed with the highest standards. Our fiber optic cabling installation services are designed to keep your business connected and running smoothly.

When you choose AccuTech Communications, you’re choosing a partner dedicated to helping your business thrive with reliable and efficient fiber optic solutions. Let’s work together to make your network stronger, faster, and more efficient.