Why Understanding Low Voltage Lighting Installation Matters for Your Business

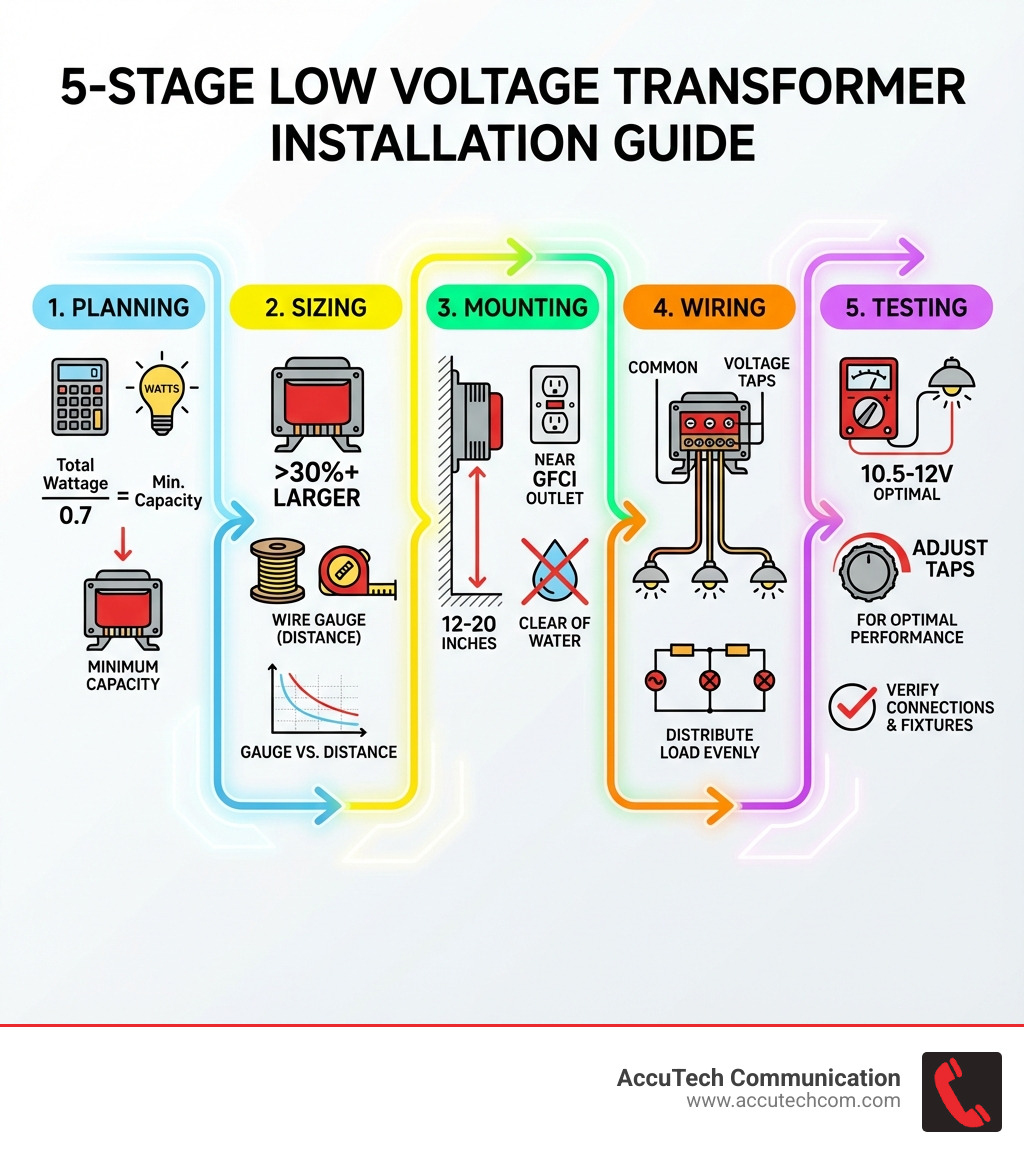

How to install a transformer for low voltage lights involves five key stages for safe, reliable operation on your commercial property:

- Planning & Sizing – Calculate total fixture load and select a transformer with at least 30% extra capacity.

- Mounting – Install the transformer vertically on an exterior wall, 12-20 inches from the ground, near a GFCI outlet.

- Wiring – Connect low-voltage cables to the transformer’s common and voltage tap terminals.

- Voltage Management – Test voltage at fixtures and adjust transformer taps to compensate for voltage drop.

- Testing – Verify all connections are secure and fixtures and controls function correctly.

Low voltage lighting improves safety and curb appeal while reducing energy costs. However, proper installation requires precise calculations, voltage management, and adherence to electrical codes to prevent hazards.

For commercial installations in Massachusetts, New Hampshire, and Rhode Island, professional installation is essential. Commercial systems involve higher loads and longer cable runs than residential projects, demanding adherence to stringent safety codes. Improper installation can lead to fire hazards, equipment failure, and costly repairs.

This guide gives business owners a clear overview of the process, from how transformers work to managing voltage drop.

I’m Corin Dolan, owner of AccuTech Communications. For decades, I’ve helped commercial clients in our three-state service area implement reliable low-voltage solutions, including understanding how to install a transformer for low voltage lights. Our expertise ensures your lighting system performs reliably for years and meets all local codes.

Important how to install a transformer for low voltage lights terms:

- how to install low voltage exterior lighting

- lv cable installation

- do you need a license to install low voltage cable

Pre-Installation Planning: Sizing and Placement

This initial phase is critical for a safe and effective lighting system. Proper planning prevents issues like overloaded circuits and dim lights, ensuring your commercial property is showcased perfectly.

Calculating the Correct Transformer Size

Sizing your transformer correctly is crucial to avoid dim lighting or system failure. An undersized unit will fail, while an oversized one is an unnecessary expense. The calculation is based on the total load of your lighting fixtures.

First, sum the wattage (or Volt-Amps, VA) of all fixtures. For example, ten 20-watt fixtures equal a 200-watt total load.

The National Electrical Code (NEC) limits continuous use circuits to 80% of their capacity. For low-voltage lighting, it’s best practice to load a transformer to only 70% of its rating to account for wire loss and ensure longevity.

Use this formula to find the minimum transformer capacity:

Total Fixture Load (watts) ÷ 0.7 = Minimum Transformer Capacity

For a 200-watt load: 200W ÷ 0.7 = 285.7 VA. You would need a 300 VA transformer, the next standard size.

For LED fixtures, you may also need to account for the power factor, which can increase the required capacity. Always check the fixture specifications. We also recommend selecting a transformer with extra capacity to accommodate future expansion.

Choosing the Optimal Mounting Location

The transformer’s location affects performance, longevity, and safety for your property in Massachusetts, New Hampshire, or Rhode Island.

Key factors for placement include:

- Proximity to GFCI Power Outlet: The transformer must plug into a GFCI-protected, outdoor-rated receptacle with an in-use weather-proof cover. Avoid using extension cords.

- Vertical Mounting and Ground Clearance: Mount the transformer vertically, with its bottom at least 12-20 inches from the ground. This ensures proper heat dissipation and prevents water entry.

- Ventilation: Ensure the location has adequate airflow. Transformers generate heat, so avoid enclosed spaces.

- Environmental Conditions: Install the unit at least 5 feet from pools/spas and 10 feet from fountains. Do not mount on combustible materials like plastic siding. In saltwater environments, protect the unit from corrosion with a weatherproof enclosure.

For more detailed information on selecting and installing low-voltage cabling, you can refer to our guide on lv cable installation.

Selecting the Right Low-Voltage Cable

The cable gauge you choose is critical for system efficiency. Thicker wires (lower gauge numbers) have less resistance and reduce voltage drop, which prevents lights from dimming over long distances.

Always use direct burial low-voltage landscape wire. For commercial applications, we recommend 12 AWG or 10 AWG wire to ensure consistent power delivery, though 16 AWG is the minimum. All installations must comply with local codes in Massachusetts, New Hampshire, and Rhode Island.

Here’s a general guide for selecting cable gauge:

| Wire Gauge (AWG) | Maximum Total Wattage (W) | Maximum Run Length (ft) |

|---|---|---|

| 16 AWG | 48 | 50 |

| 14 AWG | 70 | 75 |

| 12 AWG | 100 | 100 |

| 10 AWG | 144 | 150 |

| 8 AWG | 300 | 200+ |

Note: These are general guidelines. Precise voltage drop calculations are necessary for optimal system design.

How to Install a Transformer for Low Voltage Lights: A Step-by-Step Overview

While we recommend a professional for any commercial installation, understanding the steps is valuable. This overview covers the physical mounting and connection process.

Physically Mounting the Transformer

Proper mounting ensures the transformer is secure, ventilated, and protected.

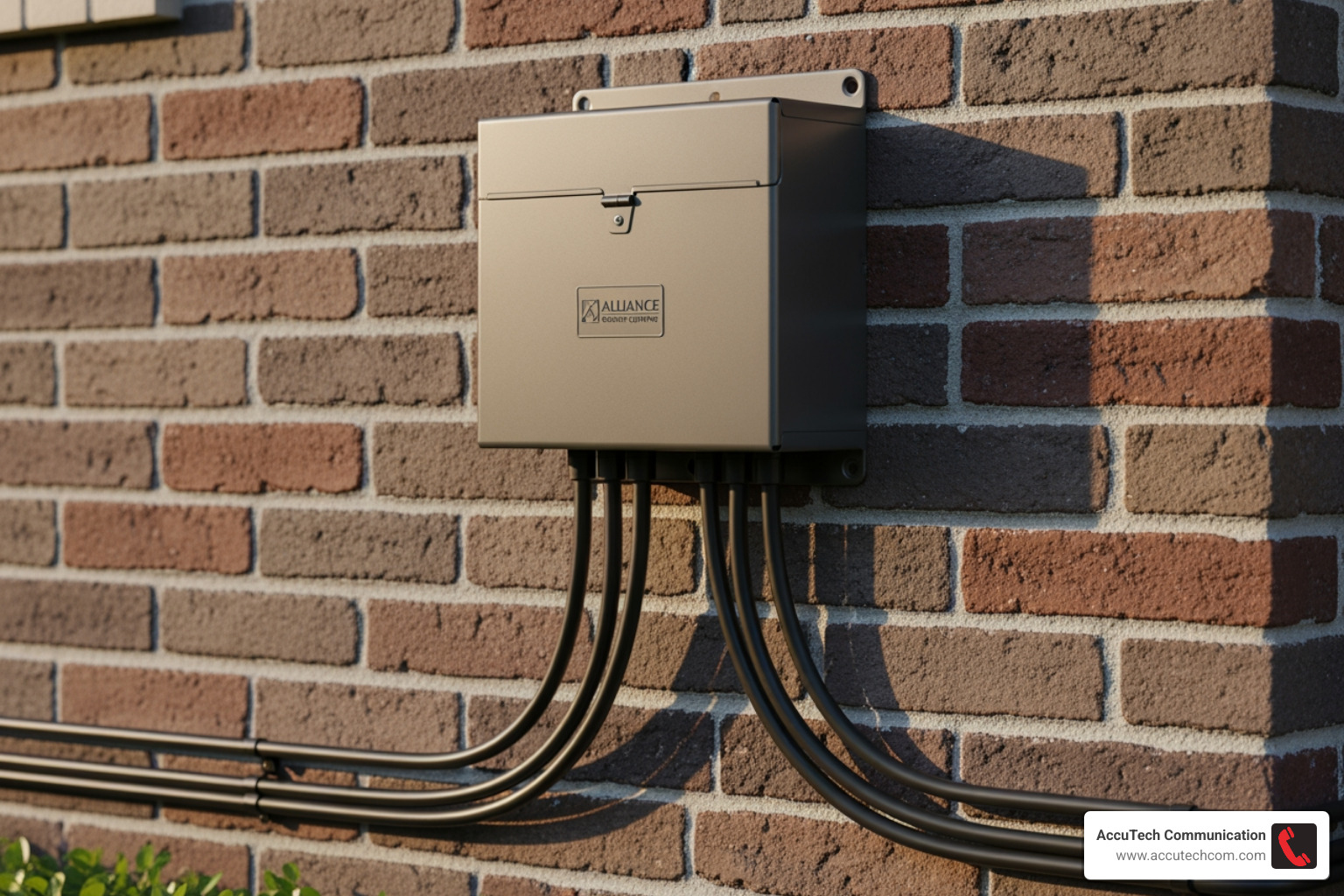

- Prepare Surface: Choose a sturdy, non-combustible surface like a brick wall. Mark the top mounting hole.

- Drill and Anchor: Drill pilot holes for wall anchors. Install the top anchor and screw, leaving a small gap.

- Hang and Secure: Hang the transformer on the top screw. Mark, drill, and install the bottom anchor and screw. Tighten both screws to secure the unit.

- Verify Position: Confirm the transformer is vertical and its bottom is 12-20 inches off the ground for proper heat dissipation and moisture prevention.

- Use Conduit (Recommended): For a clean and protected installation, run wires through a PVC conduit into a knockout at the bottom of the transformer.

How to properly connect low-voltage cables to the transformer

Precise connections to the transformer’s terminal blocks are essential for safety and reliability.

- Prepare Cables: Separate and strip about 0.5 inches of insulation from the ends of each low-voltage cable run. Twist the strands tightly. For multiple runs, label them for easier management.

- Identify Terminals: Locate the “Common” (COM) and “Voltage Tap” (e.g., 12V, 13V, 15V) terminals inside the transformer.

- Connect Wires: Loosen the terminal screws. Insert one wire from a cable run into a COM terminal and the other wire into a voltage tap terminal. Low-voltage wire has no polarity, so either wire can go to either terminal.

- Tighten Connections: Securely tighten all screw clamps. A loose connection is a fire hazard. After installation, run the system and check if any connections are hot; if so, disconnect power and re-tighten them.

Installing Optional Control Devices

Control devices like photocells and timers automate your system and save energy. Always disconnect power before installing accessories.

Installing a Photocell (Dusk-to-Dawn):

Photocells automatically turn lights on at dusk and off at dawn.

- Disconnect Power: Unplug the transformer.

- Connect Photocell: Locate the designated port on the transformer, remove any plug, and insert the photocell connector.

- Position Sensor: Place the photocell sensor where it receives natural daylight but is not affected by artificial lights.

Installing a Timer (Scheduled Lighting):

Timers operate lights on a set schedule.

- Disconnect Power: Unplug the transformer.

- Install Timer: Plug the timer module into its internal receptacle inside the transformer.

- Set Schedule: Set the current time and then program the on/off periods using the timer’s tabs or pins.

We verify all control devices during the final testing phase. For more on system setup, see our guide on how to install low voltage lighting.

Advanced Wiring Techniques and Voltage Management

Proper wiring and voltage management are key to ensuring every light in your system shines brightly and has a long lifespan. This involves choosing the right layout and compensating for natural voltage loss over distance.

Common Wiring Methods for Commercial Lighting

The right wiring method is key to distributing power efficiently and minimizing voltage drop.

- Straight Run (Daisy Chain): Fixtures are connected sequentially along one cable. Best for short runs with few fixtures, but not ideal for commercial use due to significant voltage drop at the end of the line.

- T-Method: A straight run with short branches (T-taps) to fixtures. It offers more flexibility but has similar voltage drop issues.

- Hub or Star Layout: Individual cable runs extend from the transformer to fixture groups. This is highly recommended for commercial jobs as it simplifies voltage management and isolates issues to a single run.

- Looping Method: The main cable runs from the transformer, connects all fixtures, and then loops back to the transformer. This is excellent for reducing voltage drop by allowing power to flow from two directions.

For large commercial projects, we often combine these methods for optimal voltage delivery. Understanding these layouts is part of how to install low voltage exterior lighting effectively.

How to manage voltage drop with a multi-tap transformer

Voltage drop, the loss of voltage over a cable’s length, can cause dim lights. This is a common issue in low-voltage systems, but multi-tap transformers are designed to solve it. They offer multiple output terminals (e.g., 12V, 13V, 14V, 15V) to boost the starting voltage and compensate for the loss.

Here’s how to manage voltage drop:

- Initial Connection: Connect cable runs to the 12V tap to start.

- Measure Voltage: Use a voltmeter to test the voltage at the furthest fixture on each run. The ideal range for LEDs is typically 9V to 15V. Aim for around 11V-12V for optimal performance and lifespan.

- Adjust Taps: If the voltage at a fixture is too low (e.g., 9V), move that cable run to a higher voltage tap (e.g., 14V or 15V) at the transformer. If the voltage is too high, move it to a lower tap.

- Balance Runs: Adjust each run independently until all fixtures receive the correct voltage. This ensures consistent brightness and longevity across the entire system.

Post-Installation: Testing, Troubleshooting, and Modern Alternatives

Once installed, a final check ensures everything is working correctly. It’s also important to know how to identify common issues and understand modern alternatives like Power over Ethernet (PoE) for integrated commercial systems.

Testing and Final System Checks

Thorough testing after installation is essential for safety and proper operation.

Our final check procedure includes:

- Power-Up: Plug the transformer into the GFCI outlet and ensure it doesn’t trip.

- Check Voltage: Use a voltmeter to confirm 120V at the outlet and the correct low voltage (e.g., 12V, 14V) at the transformer’s output terminals.

- Verify Fixtures: Check that all lights are on and have consistent brightness. Dim lights indicate a voltage drop issue that needs correction.

- Confirm Controls: Test timers and photocells to ensure they function as scheduled. Cover a photocell to simulate dusk and check that lights turn on.

- Check for Heat: Let the system run for five minutes, then check all low-voltage connections. Hot connections are a fire hazard; disconnect power and re-tighten them immediately.

- Bury Cables: Once the system is fully operational, bury the low-voltage cables up to 6 inches deep to protect them from damage.

Common Troubleshooting Issues

Knowing these common issues can help identify problems quickly.

- Lights are too dim: Usually caused by voltage drop. Move the affected cable run to a higher voltage tap on the transformer.

- Fixtures not turning on: Check for a tripped GFCI outlet or internal transformer circuit breaker. Also, verify control devices (timers, photocells) are working correctly and that all connections are secure.

- Circuit breaker tripping: This indicates an overload or a short circuit. Reduce the number of fixtures on the circuit or check wiring for damage.

- Flickering lights: Often caused by loose connections or a failing lamp. Tighten all connections and replace the lamp if necessary.

For commercial properties, we advise against extensive DIY troubleshooting. Professional expertise is required for safety and compliance, as detailed in our article on do you need a license to install low voltage cable.

Power over Ethernet (PoE) vs. Traditional Transformers

While traditional transformers are robust for landscape lighting, Power over Ethernet (PoE) is a modern alternative for integrated commercial systems. We help clients in Massachusetts, New Hampshire, and Rhode Island choose the best fit.

Traditional Low-Voltage Transformers:

- Pros: Cost-effective and reliable for dedicated outdoor lighting.

- Cons: Requires separate power cabling and offers limited control.

Power over Ethernet (PoE) Lighting:

PoE lighting uses standard Ethernet cables to deliver both power and data to LED fixtures, making it an Internet of Things (IoT) solution.

- Pros:

- Simplified Installation: One cable for power and data reduces complexity and cost.

- Smart Building Integration: Integrates with building management, HVAC, and security systems for centralized control and automation.

- Energy Efficiency: Offers significant energy savings through granular control and data-driven adjustments.

- Safety: Operates on safe, low-voltage DC power.

- Cons: Higher initial cost and requires network infrastructure.

When to Consider PoE: PoE is ideal for commercial projects like offices and warehouses seeking a future-proof, highly integrated lighting solution that leverages network infrastructure for smart building capabilities and advanced energy management.

Conclusion: Ensuring a Professional and Lasting Installation

Installing a low-voltage lighting transformer involves careful planning, precise calculations, and a strong understanding of electrical principles. For commercial properties in Massachusetts, New Hampshire, and Rhode Island, ensuring the system is safe, compliant with local codes, and performs reliably is paramount. While this guide provides a foundational understanding, the complexities of commercial-grade systems demand professional expertise.

At AccuTech Communications, we understand that your commercial lighting system is an integral part of your property’s security, aesthetics, and operational efficiency. Improper installation can lead to costly repairs, energy waste, and even safety hazards. Our certified technicians specialize in designing and implementing robust low-voltage solutions, including traditional transformer-based systems and advanced Power over Ethernet (PoE) lighting. We ensure every installation meets the highest standards of safety, performance, and compliance with local regulations across our service areas.

By partnering with professionals like us, you benefit from:

- Safety Compliance: Adherence to all local electrical codes and NEC standards.

- System Longevity: Proper sizing, wiring, and voltage management to maximize the lifespan of your fixtures and transformer.

- Optimal Performance: Consistent brightness and functionality across your entire lighting system.

- Integrated Solutions: Expertise in connecting lighting systems with broader network infrastructure for smart building capabilities.

For a certified, reliable, and competitively priced installation for your business, explore our low-voltage installation services. Let us illuminate your commercial space with efficiency and excellence.